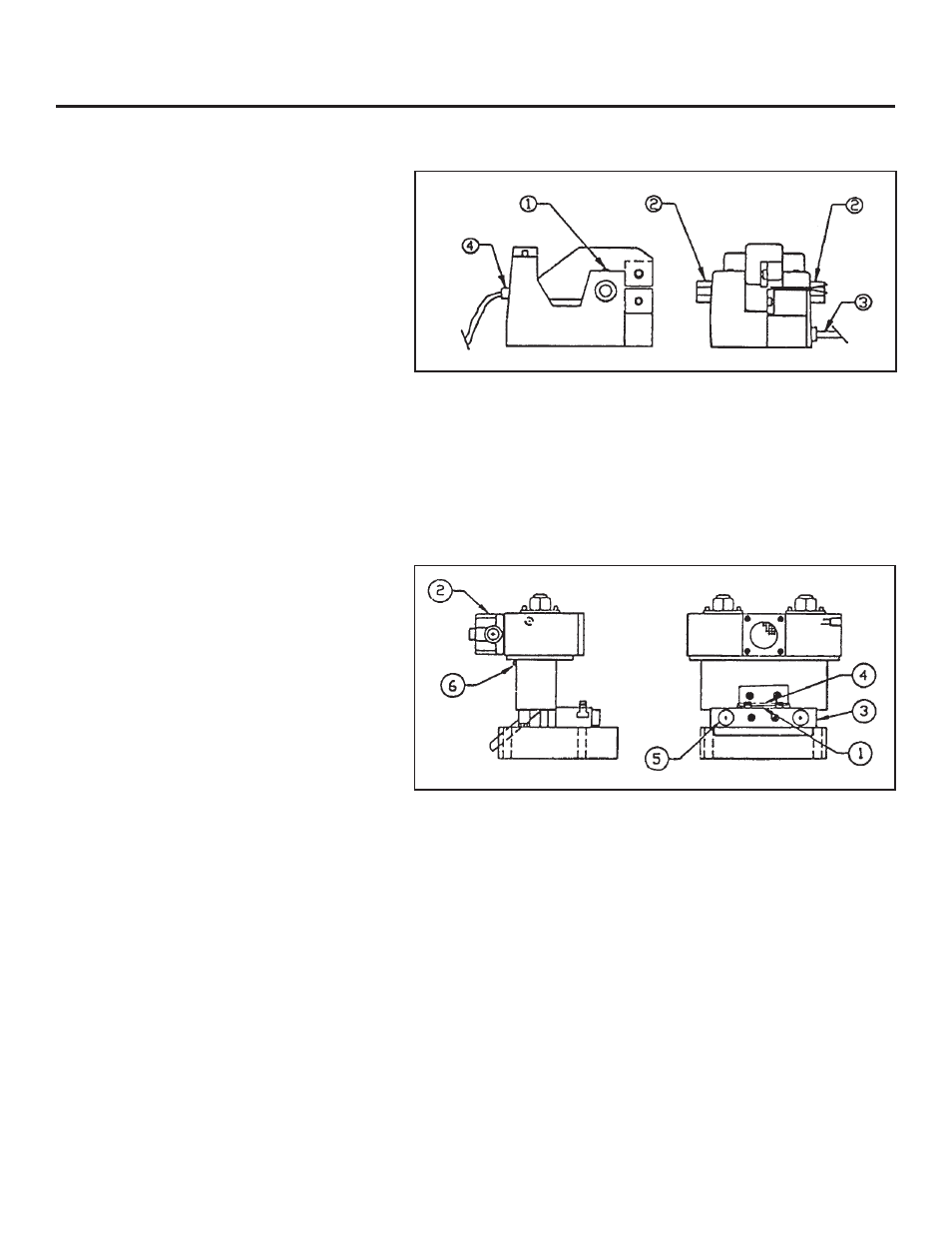

Cutter maintenance, Small cutter, Large cutter – Rapid-Air SMART MINI-SERVO FEED CUT-TO-LENGTH: SMS2, SMS4, SMS8 User Manual

Page 8

CUTTER DATA: See specific cutter specifications.

OPERATIONS: The solenoid valve, which is remote

mounted, is attached to the cutter (item #3) by a

plastic hose and advances the cutter into the mate-

rial. Compression springs return the blade to the

raised position. The cutter raised position is moni-

tored by a proximity switch mounted on the rear of

the cutter (item #4).

ADJUSTMENTS: The cutter blade may be lowered

manually by pushing down on the head of the cutter. The upper half of the cutter is attached to an adjustable slide. The

cutter clearance can be adjusted by loosening 2 screws (item #1) and rotating the hex nuts (item #2). To adjust, loosen one

side and tighten the opposite side corresponding to the side you want to adjust in order to line up the blades. Retighten the

top screws (item #1). When greasing, use Mobilux No. 2 or equivalent.

cutter maintenance

Small Cutter

CUTTER DATA: Material opening (item #1); see

specific cutter specifications.

OPERATIONS: The solenoid valve (item #2)

advances the cutter into the material and the

compression springs return the blade to the

raised position.

ADJUSTMENTS: The blade may be lowered

manually with an eccentric cam screw (item #6)

located on the upper blade assembly just under

the solenoid valve.

Large Cutter

The lower half of the cutter is attached to an adjustable slide (item #3). The cutter clearance is adjusted by loosening (2)

hex screws (item #4) on the adjusting slides and turning (2) knurled knobs (item #5) to move the lower blade horizontally in

and out.