Troubleshooting, Maintenance procedures, precautions and safety, Continued) – Rapid-Air SMART MINI-SERVO FEED CUT-TO-LENGTH: SMS2, SMS4, SMS8 User Manual

Page 7: Problem cause remedy, Maintenance procedures precautions and safety

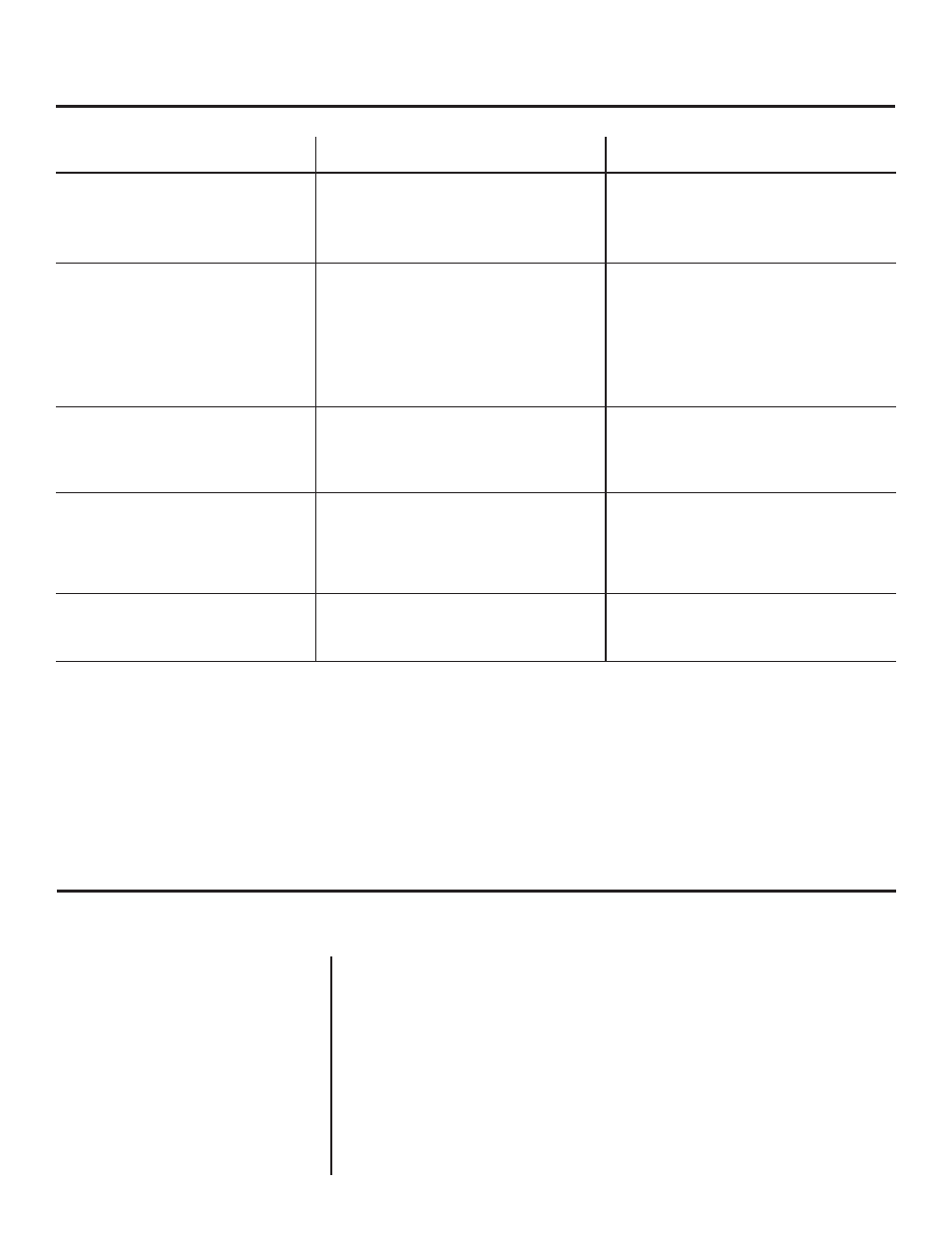

Problem Cause Remedy

troubleshooting

(continued)

Material feeds off center

No automatic cycle

Servo squeals

Fault signal on drive is displayed

Cannot program unit from display

– Edge guides not set properly.

– Material not centered to feed.

– Bad material.

– No cutter signal.

– Controller fault.

– Servo fault.

– Program error.

– Servo velocity gain too high.

– Belt too loose or tight.

– Servo fault.

– Material jam.

– Power surge / failure.

– Program fault.

– Set edge guides.

– Center material.

– Try new roll of material.

– Check cutter prox. SW. input to

servo control.

– Check lights on drive.

– Check parameters on display.

– Consult factory.

– Readjust belt tension.

– Recycle power.

– Check cutter.

– Check / recycle power.

– Check drive and call factory.

maintenance Procedures, Precautions and safety

DAILY

Wipe off feed rolls.

Clean any dirt from servo unit.

Clean any dirt from operators pendant.

wEEkLY

Check wear pattern of rolls.

MONThLY

Check cables for cuts or wear.

NEVER – Put screwdrivers or foreign materials in feed rolls.

NEVER – Hold onto material as it is being fed through the servo.

NEVER – Wear neckties around the servo feed rolls.

NEVER – Force the rolls open by prying on them.

NEVER – Modify the mechanical aspects of the servo feed.

CAUTION – Contact the factory before drilling any holes in the unit.

CAUTION – Wear proper eye protection when working around the servo.

CAUTION – Do not wear loose clothing around the servo feed rolls.

Maintenance Procedures

Precautions And Safety