Installation, Electrical connections and operations, Cable installation – Ramsey Winch RE 8000/10000/12000T User Manual

Page 4: Operating instructions, Maintenance

Installation

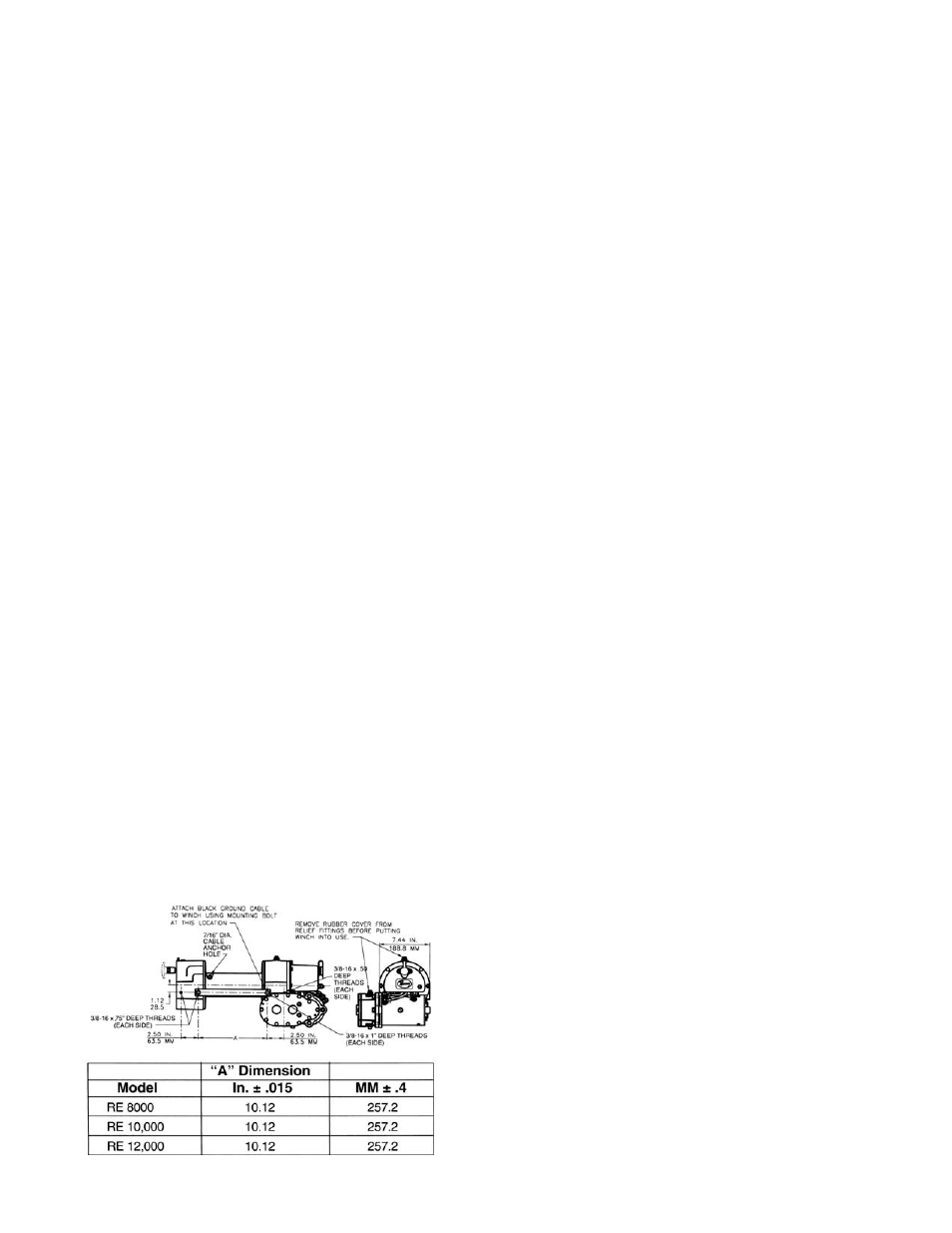

It is recommended that Ramsey mounting kits be used to

mount the winch. They are designed to align the winch and dis-

tribute up to the full rated load correctly to avoid possible dam-

age to the winch or the vehicle. NOTE: If Ramsey kits are not

used, the winch must be mounted to angles (3/8 x 2 1/2 x 3

min.) or in a frame with both sides of the clutch housing and

gear housing bolted to the angles or frame. See below for

dimensions.

Substitution of attaching hardware items (bolts, nuts, or wash-

ers) different from those supplied with your winch mounting kit

can lead to failure causing damage or serious injury. (Use SAE

grade 5 bolts or better). See diagram below for recommended

mounting dimensions.

Electrical Connections and Operations

For normal self recovery work, your existing electrical system is

adequate. Your battery must be kept in good condition. A fully

charged battery and proper connections are essential. Run the

vehicle engine during winching operation to keep the battery

charged.

An emergency stop switch (reference Ramsey part number

282053 is required between the positive (+) battery terminal

and the red battery cable from winch. An overload device is

required to prevent winch from exceeding the rated line pull.

Connect red cable to battery positive (+) terminal and stud on

plastic solenoid cover on winch. IMPORTANT: Hold inner nut

with open end wrench while tightening outer nut.

Connect black cable to negative (-) terminal of battery and to

winch mounting bolt nearest drum, as shown below. A good

electrical ground is required for proper performance.

The remote control switch is water proof and practically inde-

structible. It has push button stations on either side. It is

designed this way to prevent quick winch reversals which lead

to solenoid failure. Make sure the winch motor has stopped

fully before reversing.

When first setting up your winch, follow the directions for

inserting the proper “IN” or “OUT” sign in the thumb button.

The switch is also color coded to aid you in not having to guess

at the direction your winch will run. DO NOT LEAVE SWITCH

PLUGGED IN WHEN WINCH IS NOT IN USE.

Cable Installation

1. Unwind cable by rolling it out along the ground to prevent

kinking. Securely wrap end of cable opposite hook, with plas-

tic or similar tape to prevent fraying.

2. Insert the end of the cable, opposite hook end, under drum

and into the 7/16” dia. hole in drum barrel. Secure cable to

drum barrel, using setscrew provided with winch. TIGHTEN

SETSCREW SECURELY.

3. Carefully run winch in the “reel-in” direction. Keeping ten-

sion on end of cable, spool all the cable onto drum, taking care

to form neatly wrapped layers.

Inspect the cable frequently. If the cable becomes frayed with

broken strands, replace immediately. Cable and hook assem-

blies may be purchased from a Ramsey distributor.

Operating Instructions

The RAM-LOK

TM

semi-automatic clutch provides free spooling

and clutch engagement with cable drum. With the clutch dis-

engaged, the cable can be pulled off the drum by hand. For

winching in the load, the clutch must be fully engaged with the

drum.

To disengage the clutch, run the winch in the reverse (reel-out)

direction until the load is off the cable and the cable drum stops

turning. Pull outward on the clutch handle, rotate it counter-

clockwise 90° and release. The clutch is now locked out and the

cable may be pulled off by hand. (Note: If the clutch handle can

not be pulled out, again run the winch momentarily in reverse to

relieve pressure on the clutch jaws). Warning: Do not attempt

to disengage the cable drum when there is a load on the cable.

Maintenance

Check monthly the action of the sliding clutch, making sure it is

fully engaging and disengaging with the cable drum. With the

clutch in the engaged position, remove the plastic plug in top of

the housing and observe if the clutch is fully engaging. If clutch

is not fully engaging, inspect clutch shifter assembly parts,

check for damage or excessive wear and replace as necessary.

Observe the jaws on both the clutch and cable drum, checking

for rounding of the drive faces. If rounding has occurred, they

should be replaced immediately.

4

T

T

T