Typical layout, Sch 2,900, Sch 3,600 – Ramsey Winch SCH-4900 User Manual

Page 5

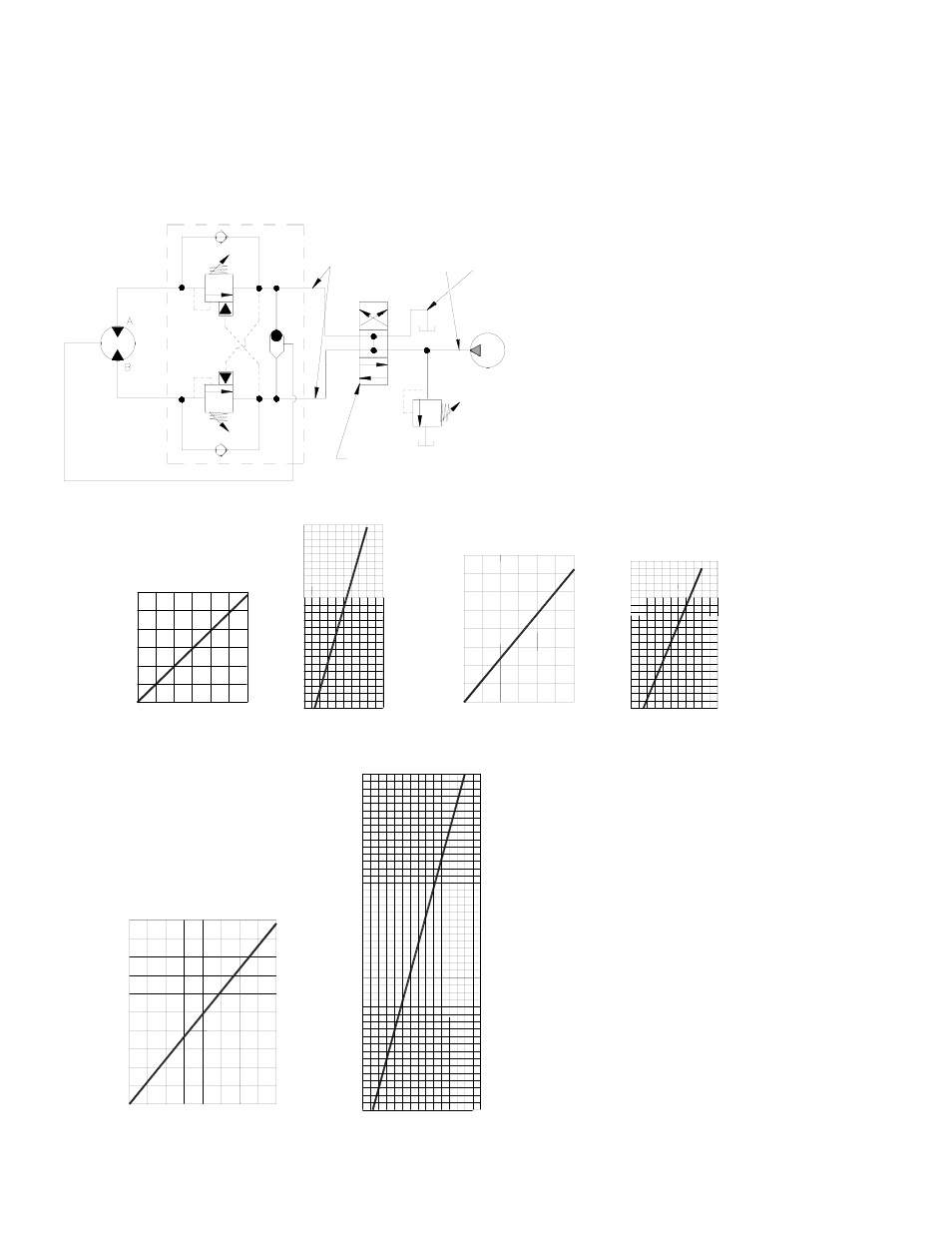

TYPICAL LAYOUT

PUMP

(.75 I.D. MINIMUM)

LOW PRESSURE LINE

(.50 I.D. MINIMUM)

HIGH PRESSURE LINE

SEE PERFORMANCE

RATED LOAD:

PRESSURE AT

MAX. FLOW &

(MOTOR SPOOL)

4 WAY VALVE

3 POSITION

RELIEF

SYSTEM

PORT

BRAKE

MOTOR

WITH BRAKE RELEASE SHUTTLE

DUAL-A & B PORT CONTROL

CHARTS BELOW

60

50

40

20

30

L

INE PULL

-F

IRST L

AYER (

L

B.)

L

INE SPEED-

F

IRST LAYER (

F

PM

)

WORKING PRESSURE, PSI

0

0

600

1,000

2,000

1,800

1,200

10

3,000

FLOW (GPM)

5

0

10

SCH 2,900

10

0

5

FLOW (GPM)

4,000

3,000

10

1,200

1,800

2,000

1,000

600

0

0

WORKING PRESSURE, PSI

L

INE SPEED-

F

IRST LAYER (

F

PM

)

L

INE PULL

-F

IRST L

AYER (

L

B.)

30

20

40

50

SCH 3,600

50

40

45

5,000

1,600

15

10

0

5

FLOW (GPM)

4,000

3,000

5

800

1,200

2,000

1,000

400

0

0

WORKING PRESSURE, PSI

L

INE SPEED-

F

IRST LAYER (

F

PM

)

L

INE PULL

-F

IRST L

AYER (

L

B.)

15

10

35

20

25

30

SCH 4,900

9.6 cu.in. Motor

11.9 cu.in. Motor

18.7 cu.in. Motor

3

PERFORMANCE CHARTS

HYDRAULIC SYSTEM REQUIREMENTS

Refer to the performance charts below to properly match your hydraulic system to the winch performance. The

charts consist of: (1) first layer line pull (LB) vs. working pressure (PSI) and (2) first layer line speed (FPM) vs. flow

(GPM). A motor spool directional control valve is required.