Ramsey Winch CABLE TENSIONER AIR ACTUATED RPH 20000/25000 256086, 256087 User Manual

Ramsey Winch For the car

INSTALLATION INSTRUCTIONS FOR

AIR ACTUATED CABLE TENSIONER KITS #256086& 256087

These Tensioner Kits are designed specifically for the Ramsey Winch Models RPH 20,000 and RPH 25,000 Series

Winches. The Tensioners require an independent, adjustable regulated air supply of between 50 psi and 90 psi. If you

do not provide an adjustable air supply you will not be able to adjust the effort of the free-spool. If your vehicle is not

equipped with an independent, adjustable air pressure regulator (used only for the tensioner) or you are unable to adjust

it to a setting in the range indicated, order pressure regulator kit #256092 from Ramsey.

INSTALLATION PROCEDURE

Disengage the winch clutch and free spool all the cable except for the last

wrap off the winch. Lay cable out in a straight line behind the truck to pre-

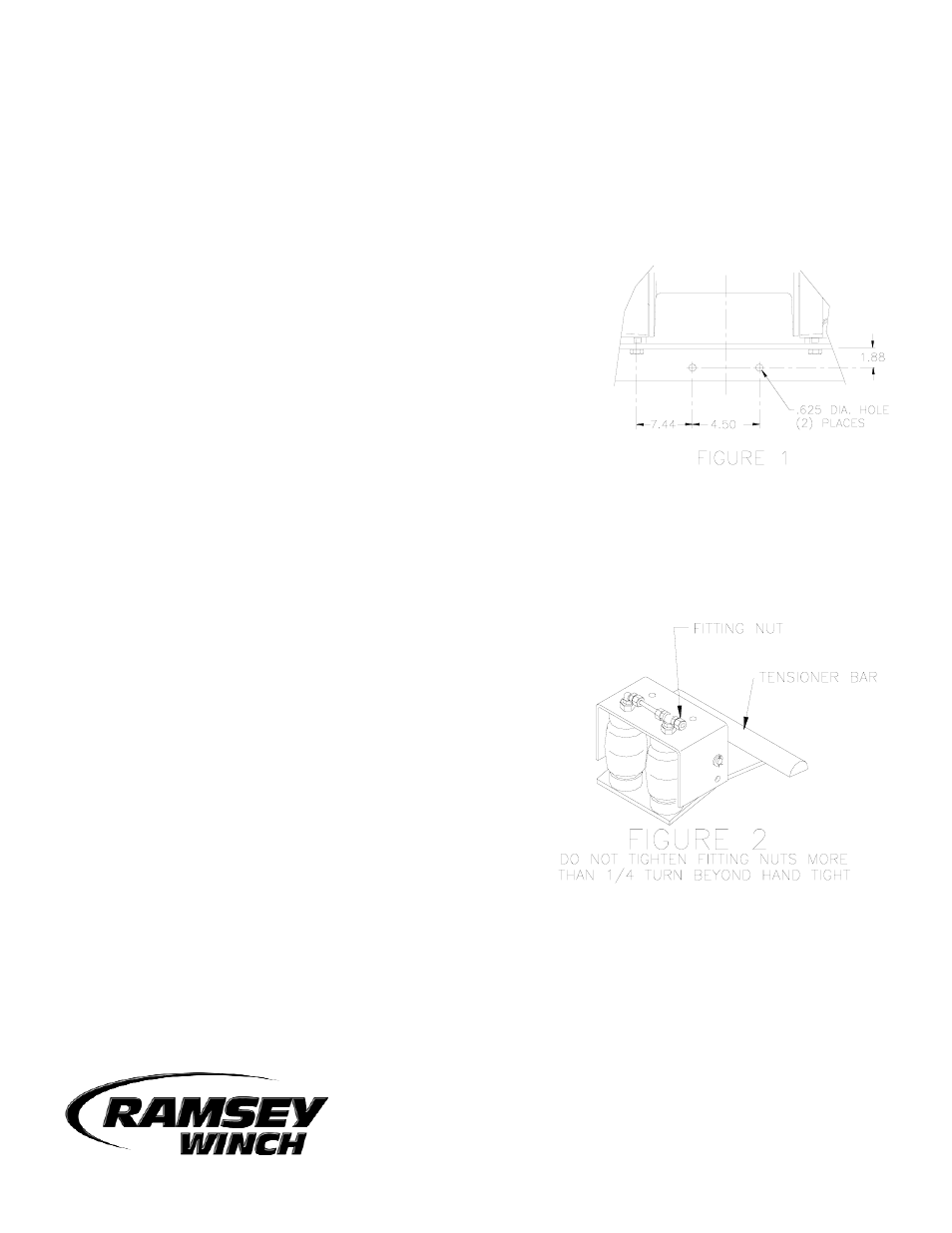

vent kinking. Mark mounting hole center's as shown in Fig. 1. Place cable

tensioner assembly over marked hole positions (for underwound installations

place assembly on top of angle). Observe location of tensioner bar and center

it between the drum flanges. Adjust hole locations as necessary to maintain

centered position. Drill two .625 diameter holes through the horizontal flange

of the angle component of the winch frame as shown in FIG. 1.

OVER-WOUND installations -- Place the supplied mounting bolts through the

mounting holes of the Tensioner bracket. Carefully position the bracket over

the previously drilled holes in the flange of the angle component of the winch

frame, allowing the bolts to fall through the holes. Loosely attach the washers

and nuts.

UNDER-WOUND installations -- clamp the tensioner in position under the previously drilled holes, place the bolts

through the bracket mounting holes and into the winch frame. Loosely attach the washers and nuts.

Center the tension bar between the drum flanges with a scale or tape measure and tighten the bolts securely (75 ft-lbs.

of torque).

If you removed the cable entirely from the winch or this is a

new installation: The cable tensioner is not intended to be ener-

gized on a bare drum. Before applying air to the cable tensioner,

engage the clutch and run the winch in the reel in direction winding

one full wrap of cable on the drum. This prevents damage to the

cable tensioner.

Attach the regulated air supply to the “T” fitting on the tensioner

(see FIG. 2). Hand tighten the nut. Do NOT tighten more than 1/4

turn beyond hand tight. Apply air to the tensioner. Engage the

clutch and run the winch in the reel in direction winding about five

wraps of cable onto the drum and stop. Using a hammer tap these

five wraps tightly over against the cable anchor flange side of the

cable drum. Finish winding all the cable onto the cable drum. As

cable winds onto the drum, watch the tensioner. Tensioner must be

free to move without obstruction to function properly. If tensioner

touches any surrounding structure, correct the problem.

Adjust the free-spool effort of the cable tensioner. Disengage the winch clutch and free spool some cable off the drum.

Adjust the air pressure to the cable tensioner to achieve the desired free spool effort that also prevents "bird nesting" of

the cable.

CAUTION: DO NOT EXCEED 100 PSI AIR PRESSURE TO THE ACTUATORS.

OPERATION

Once you have adjusted the air pressure to the desired level, only minor adjustment may be required if your pressure

regulator setting drifts.

RAMSEY WINCH COMPANY

P.O. BOX 581510

TULSA, OKLAHOMA 74158

KI-912574-1097-C