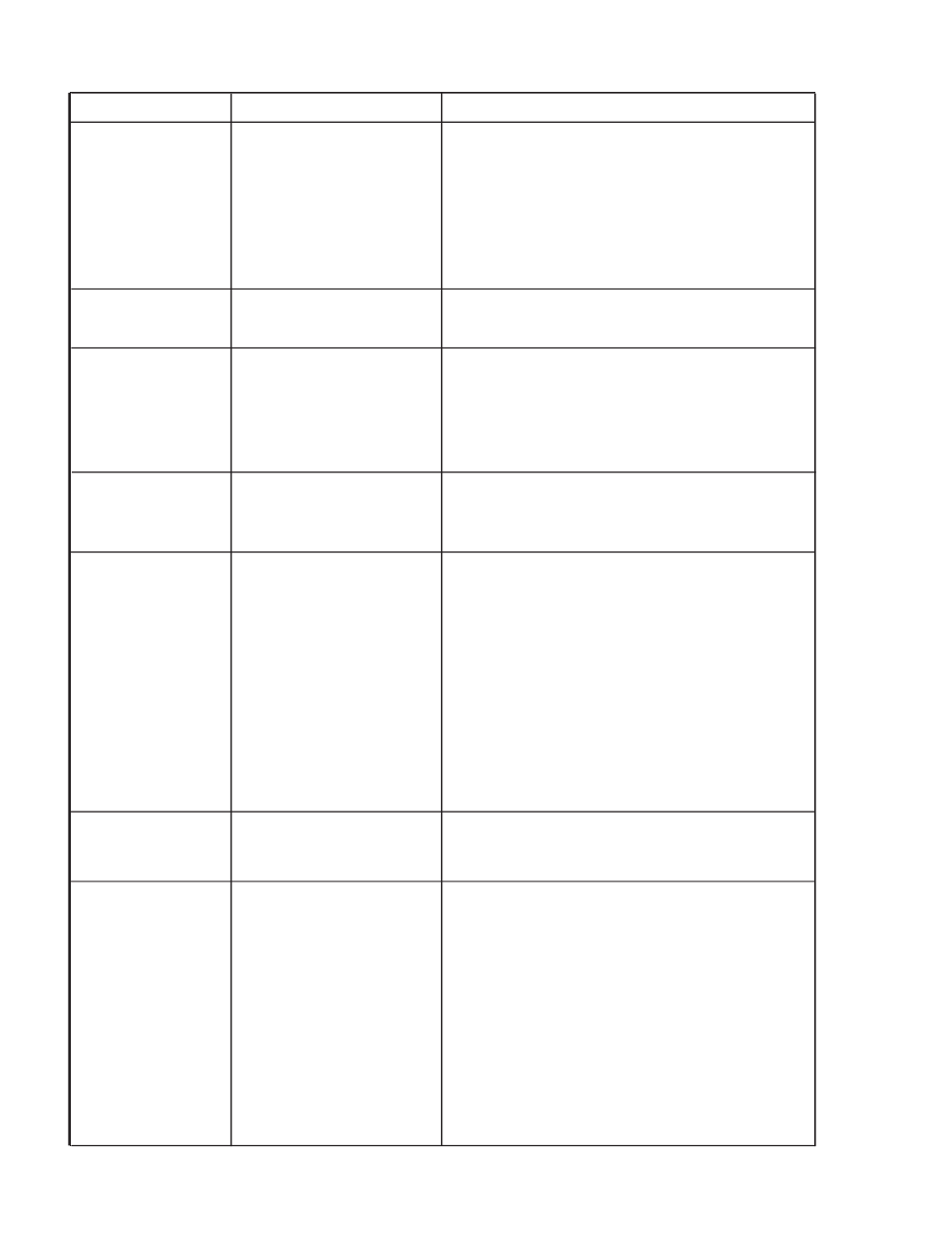

Troubleshooting guide – Ramsey Winch REP-5000 (SERIES WOUND MOTOR) User Manual

Page 6

MOTOR RUNS

EXTREMELY HOT

MOTOR RUNS,

BUT DRUM DOES

NOT TURN

MOTOR WATER

DAMAGE

D

CABLE DRUM WILL

NOT FREESPOOL

OR IS DIFFICULT

TO FREESPOOL

Troubleshooting Guide

MOTOR RUNS

IN ONLY ONE

DIRECTION

MOTOR RUNS,

BUT WITH

INSUFFICIENT

POWER OR WITH

LOW LINE SPEED

MOTOR WILL

NOT OPERAT

E

6

Long period of operation

Cooling-off periods are essential to prevent

overheating.

Check battery terminal voltage under load. If 10

volts or less for a 12 volt battery or 20 volts or less for a

24 volt battery, replace or parallel another battery to it.

Insufficient battery

Bad Connection

Insuff cient charging system

Check battery cable for corrosion; clean and grease.

Replace with larger capacity charging system.

Clutch not engaged

Defective remote control

switch

Defective Motor

Loose connections

If solenoids operate, confirm defective motor by

checking for voltage at armature post; replace motor.

Tighten connections on bottom side of hood

and on

motor.

If clutch engaged but symptom still exists, it will be

necessary to disassemble winch to determine cause

and repair.

Defective solenoid or

stuck solenoid

Jar solenoid assembly to free contacts. Confirm

defective solenoid by applying 12 or 24 volts as

appropriate to coil terminal (it should make an audible

click when energized).

To confirm, disengage winch clutch, remove

remote control switch from the socket and jump

pins at 8 and 4 o’clock. Motor should run.

Submerged in water or

water from high pressure

car wash.

Allow to drain and dry thoroughly, then run motor

without load in short bursts to dry windings.

Clutch not disengaged

Winch not mounted square-

ly causing end bearing to

bind drum

Some or all of the (6)

414861 f at capscrews

attaching the 479007 ring

gear retainer are too tight

Check clutch operation according to nameplate.

Make sure clutch shifter knob is fully at “OUT” posi-

tion.

Check mounting to see that the installation instruc-

tions on page 4 have been followed.

Remove the gear housing cover, 413018, and all

gears from inside the gear housing. Disengage the

clutch and check to see that the ring gear will rotate

by hand. If it will not, using a hex

wrench, slightly loosen all six capscrews and then

snugly retighten.

Jar solenoid assembly to free contacts. Confirm

defective solenoid by applying 12 or 24 volts as

appropriate to coil terminal (it should make an audible

click when energized).

To confirm, disengage winch clutch, remove remote

control switch from the socket and jump pins at 8 and

4 o’clock. Motor should run. Jump pins at 8 and 10

o’clock. Motor should run.

Defective solenoid or stuck

solenoid

POSSIBLE CAUSE

CONDITION

CORRECTION