Ramsey Winch RE-12000 SPECIAL FOR H-1 HUMMVEE MOUNTING KIT User Manual

Page 5

Spool the cable properly on the drum when storing between

each usage.

Check the oil level in the gear boxes every six months.

At the same time, check electrical connections and mounting

bolts--tighten if necessary.

Corrosion on electrical connections will reduce performance

or may cause a short. Clean all connections, especially in

remote switch receptacle. In salty environments use a silicon

sealer to protect from corrosion.

Be sure the winch has plenty of battery power available.

Replace oil annually or more often if winch is used frequently.

Fill the worm gear box with 3/4 pint of SAE 140 EP oil.

Use 1/2 pint of SAE 20 for spur gear box. Apply cup grease to

lube fitting at top of clutch housing. Should winch be sub-

merged for a brief period, drain oil, flush and replace oil in

gear boxes, and grease all fittings (See Troubleshooting Guide

below).

To minimize corrosion of the internal motor components that

may occur due to condensation, power the winch in or out

periodically. Energizing the motor will generate heat, which will

dissipate any moisture buildup in the motor. This should be

performed at periodic intervals (such as with each oil change

of your vehicle).

Lubricate cable periodically using light penetrating oil. Inspect

for broken strands and replace if necessary. Install new cable

per “Cable Installation” on page 4.

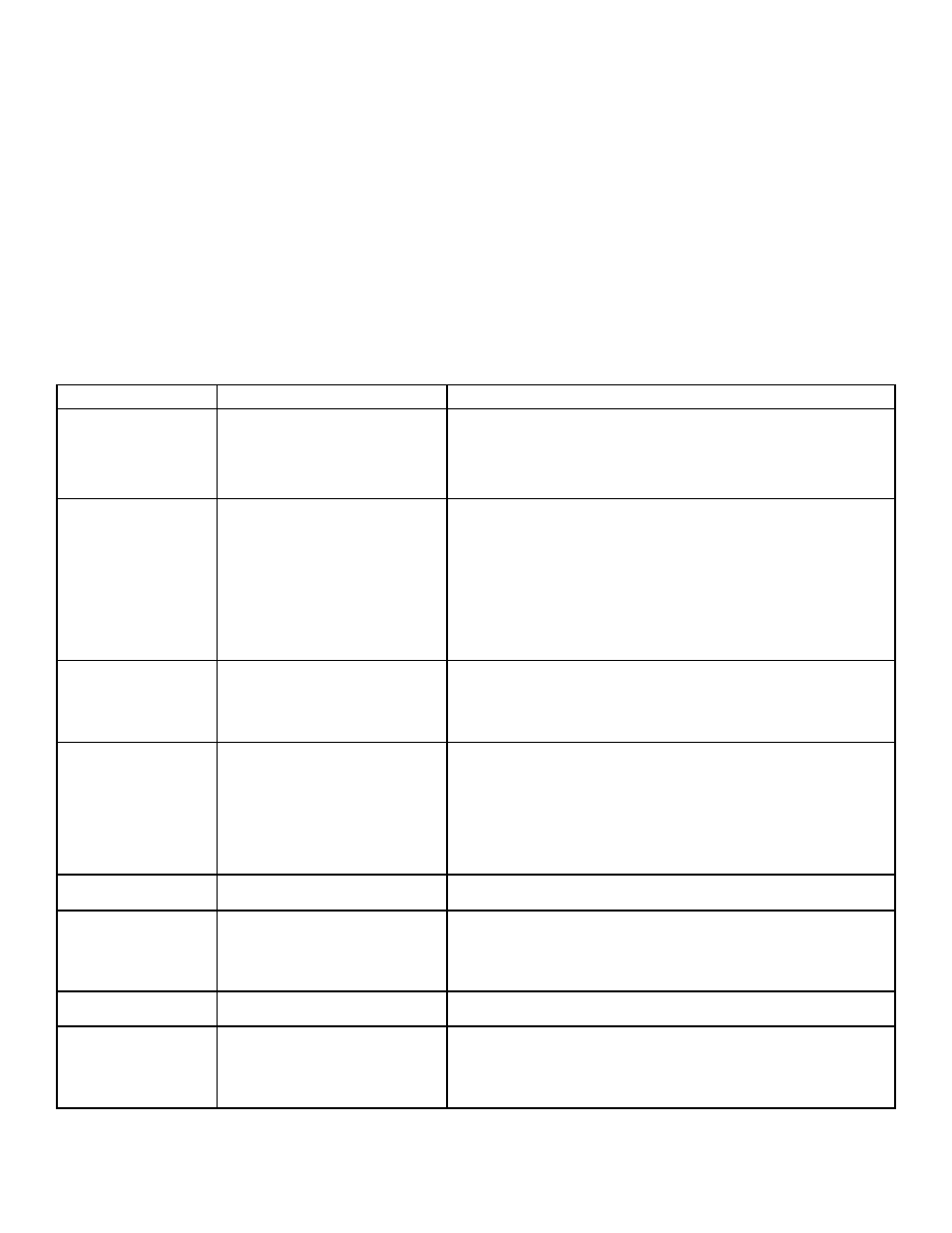

Troubleshooting Guide

CONDITION

POSSIBLE CAUSE

CORRECTION

MOTOR RUNS IN ONE

DIRECTION ONLY.

(1) Inoperative solenoid or stuck solenoid. (1) Jar solenoid to free contacts. Check by applying 24 volts to coil terminal (it

should make an audible click when energized).

(2) Inoperative remote control switch.

(2) Disengage winch clutch, remove remote control switch plug from the socket

and jump pin at 8 and 4 o’clock. Motor should run. Jump pins at 8 and 10 o’clock.

Motor should run.

MOTOR RUNS EXTREMELY

HOT

MOTOR RUNS, BUT WITH

INSUFFICIENT POWER, OR

WITH LOW LINE SPEED.

(1) Long period of operation.

(1) Cooling off periods are essential to prevent overheating.

(2) Insufficient battery.

(2) Check battery terminal voltage under load. If 20 volts or less, replace or parallel

another battery to it.

(3) Electrical cable from battery to winch

or ground strap from engine block to vehi-

cle chassis too small.

(3) Must be #2 gauge or larger if longer than 15 ft.

(4) Bad electrical connections.

(4) Check all connections for looseness or corrosion; tighten, clean and grease.

(5) Insufficient charging system.

(5) Replace with larger capacity charging system.

MOTOR RUNS, BUT DRUM

DOES NOT TURN.

(1) Clutch not engaged.

(1-4) If clutch is engaged but symptom persists, it will be necessary to disassem-

ble winch to determine cause and repair.

(2) Sheared drum shaft key.

(3) Stripped bronze gear.

(4) Parted shaft.

MOTOR WILL NOT OPER-

ATE.

(1) Inoperative solenoid or stuck solenoid. (1) Jar solenoid to free contacts. Check by applying 24 volts to coil terminal (it

should make an audible click when energized).

(2) Inoperative remote control switch.

(2) Disengage winch clutch, remove remote control switch plug from the socket

and jump pin at 8 and 4 o’clock. Motor should run. Jump pins at 8 and 10 o’clock.

Motor should run.

(3) Inoperateve motor.

(3) If solenoids operate, check for voltage at armature post; replace motor.

(4) Loose connections.

(4) Tighten connections on bottom side of hood and on motor.

MOTOR WATER DAMAGED. Submerged in water or water from high

pressure car wash.

Allow to drain and dry thoroughly, then run motor without load in short bursts to

dry windings.

CLUTCH INOPERATIVE OR

BINDS UP.

(1) Dry or rusted shaft.

(1) Clean and lubricate.

(2) Bent yoke.

(2) Replace yoke or shifter assembly.

(3) Keys pulled out of shape by overload. (3) If drum shaft keyways are rounded or damaged replace shaft and keys. If not,

file off burrs and replace keys.

CLUTCH SPRING DOES NOT

OPERATE.

Broken spring.

Replace spring.

OIL LEADS FROM HOUSING (1) New seal.

(1) New seals sometimes leak until seated to shaft.

(2) Seal damaged or worn.

(2) Replace.

(3) Too much oil.

(3) Drain excess oil per lubrication instructions above.

(4) Damaged gasket.

(4) Replace.

5