Rope inspection – Ramsey Winch ATV-3000 W_SYNTHETIC ROPE User Manual

Page 7

7

Rope Inspection

When rope is first used, the outer filaments of the rope will quickly fuzz up. This is the result

of these filaments breaking and this roughened surface will actually protect the fibers under-

neath. The condition should stabilize, not progress. If the surface roughness increases,

excessive abrasion is taking place and strength is being lost.

Look closely at both the inner and outer fibers. When either is worn the rope is obviously

weakened. Open the strands and look for powdered fiber--this is a sign of internal wear.

Rope should be replaced when

·

Rope bulk anywhere along the length is reduced by 25% or more by abrasion

·

Two or more adjacent strands are cut.

·

Flat areas or lumps are found that are not eliminated by flexing rope.

·

Excessive fused or melted fibers are found. Any such areas will be stiff and the

rope will have a glazed appearance.

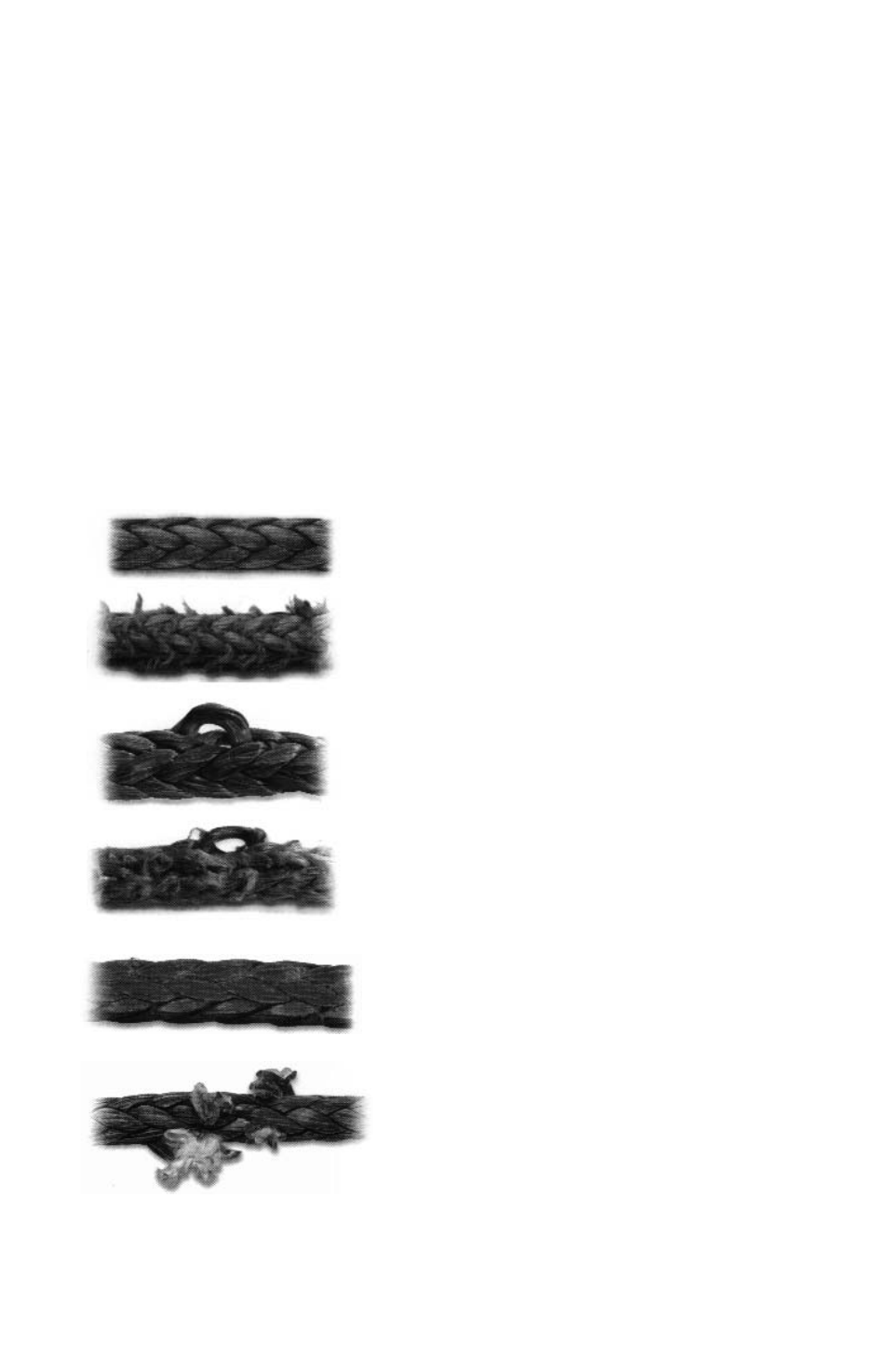

Examples:

Rope with original bulk

Rope displaying 25% strand volume reduction from abra-

sion--rope should be replaced.

Rope strand showing full volume

Rope strand reduced by 25% abrasion--rope should be

replaced.

Rope exhibits fiber-set from compression. A slight

sheen is visible. This is not a permanent characteristic

and can be eliminated by flexing the rope.

Rope displays two adjacent cut strands--rope should

be replaced.