Pressure washer, Caution, Diagram a: not grounded to frame – Pumptec PRESSURE WASHER User Manual

Page 5: Inlet condition checklist, Inlet supply, Inlet line size, Inlet pressure

5

Version 110112

Pumptec Operating Instructions and Parts Manual

PRESSURE WASHER

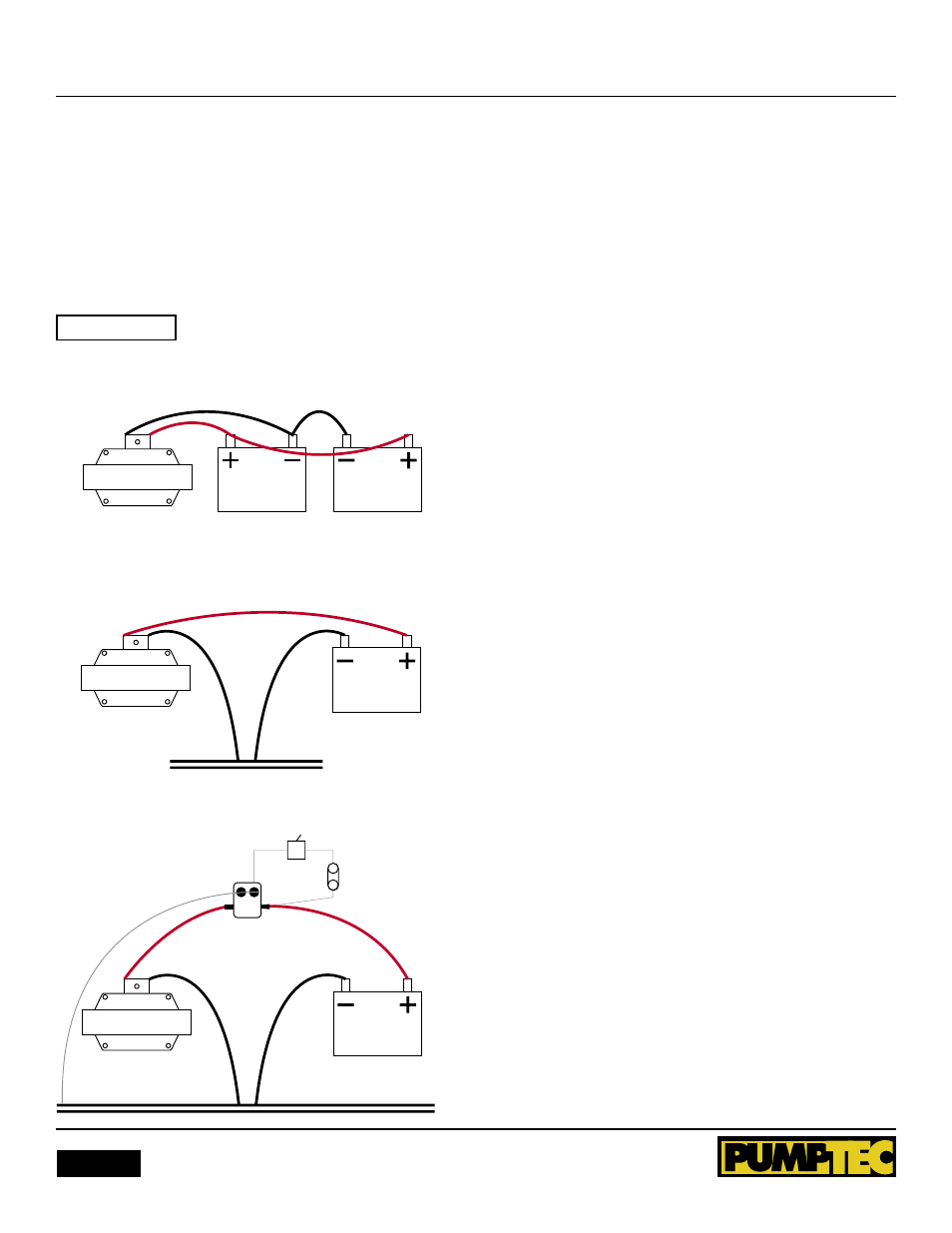

systems problem. Almost every other problem will be related

to electrical issues.

The most common electrical problems are poor connections.

Among those: Corroded battery terminals, corroded ground

wire, corroded wire connector, inadequate wire size for load

and damaged wire.

Our 12 volt motors with switches have circuit breakers built

into the switch box.

cAutIoN!

CIRCUIT BREAKERS WILL AUTOMATICALLY

RESET. THE MOTOR WILL RESTART AUTOMATICALLY.

DIAgRAM A: nOT gROUnDED TO FRAME

ONͳOFF SWITCH

& CIRCUIT BREAKER

MOUNTED ON MOTOR

DEEP CYCLE BATTERY

TRUCK BATTERY

ONͳOFF SWITCH

& CIRCUIT BREAKER

MOUNTED ON MOTOR

TRUCK BATTERY

TRUCK FRAME

ONͳOFF SWITCH

& CIRCUIT BREAKER

MOUNTED ON MOTOR

TRUCK BATTERY

TRUCK FRAME

GROUND

FUSE

REMOTE CONTROL

SWITCH

DIAgRAM B: gROUnDED TO FRAME

DIAgRAM C: REMOTE SWITCH

IMPortANt:

Warranty void if you connect electrical wires

backwards. Red is positive (+). Black is negative (-). Retrace

electrical wires to battery to be absolutely certain (+) terminal

on battery goes to red motor wire. Black wire on motor goes

directly to (-) terminal on battery or truck frame.

iNLEt CONDitiON CHECkLiSt

Inadequate inlet conditions can cause serious malfunctions in

the best designed pump. Surprisingly, the simplest of things

can cause the most severe problems or go unnoticed to the

unfamiliar or untrained eye. REVIEW THIS CHECKlIST BEFORE

OPERATIOn OF AnY SYSTEM. Remember, no two systems are

alike so there can be no OnE best way to setup a system. All

factors must be carefully considered.

iNLEt SUPPLy

should exceed the maximum flow being

delivered by the pump to assure proper performance.

• Open inlet shut-off valve and turn on water supply to avoid

starving the pump. DO nOT RUn PUMP DRY.

• Avoid closed loop systems especially with high temperature,

ultra-high pressure or large flows. Conditions vary with

regulating/unloader valve.

• When using an inlet supply reservoir, size it to provide

adequate liquid to accommodate the maximum output of

the pump, generally a minimum of 6-10 times the gPM

(however, a combination of system factors can change this

requirement).

iNLEt LiNE SizE

should be adequate to avoid starving the

pump

• line size must be a minimum of one size larger than the pump

inlet fitting. Avoid tees, 90-degree elbows or valves in the

inlet line of the pump to reduce the risk of flow restriction

and cavitations.

• The line MUST be a FlEXIBlE hose, nOT a rigid pipe, and

reinforced on SUCTIOn systems to avoid collapsing.

• The simpler the inlet plumbing the less the potential for

problems. Keep the length to a minimum, the number of

elbows and joints to a minimum (ideally no elbows) and the

inlet accessories to a minimum.

• Use pipe sealant to assure airtight, positive sealing pipe

joints.

iNLEt PrESSUrE

should fall within the specifications of

the pump.

• High RPM, high temperatures, low vapor pressures or high

viscosity may increase acceleration loss of liquids.

• Optimum pump performance is obtained with +20 PSI (1.4

BAR) inlet pressure. With adequate inlet plumbing, most

pumps will perform with flooded suction.

ONͳOFF SWITCH

& CIRCUIT BREAKER

MOUNTED ON MOTOR

DEEP CYCLE BATTERY

TRUCK BATTERY

ONͳOFF SWITCH

& CIRCUIT BREAKER

MOUNTED ON MOTOR

TRUCK BATTERY

TRUCK FRAME

ONͳOFF SWITCH

& CIRCUIT BREAKER

MOUNTED ON MOTOR

TRUCK BATTERY

TRUCK FRAME

GROUND

FUSE

REMOTE CONTROL

SWITCH

ONͳOFF SWITCH

& CIRCUIT BREAKER

MOUNTED ON MOTOR

DEEP CYCLE BATTERY

TRUCK BATTERY

ONͳOFF SWITCH

& CIRCUIT BREAKER

MOUNTED ON MOTOR

TRUCK BATTERY

TRUCK FRAME

ONͳOFF SWITCH

& CIRCUIT BREAKER

MOUNTED ON MOTOR

TRUCK BATTERY

TRUCK FRAME

GROUND

FUSE

REMOTE CONTROL

SWITCH