Typical installation – Powermate IV7518075 User Manual

Page 6

6 - ENG

200-2909

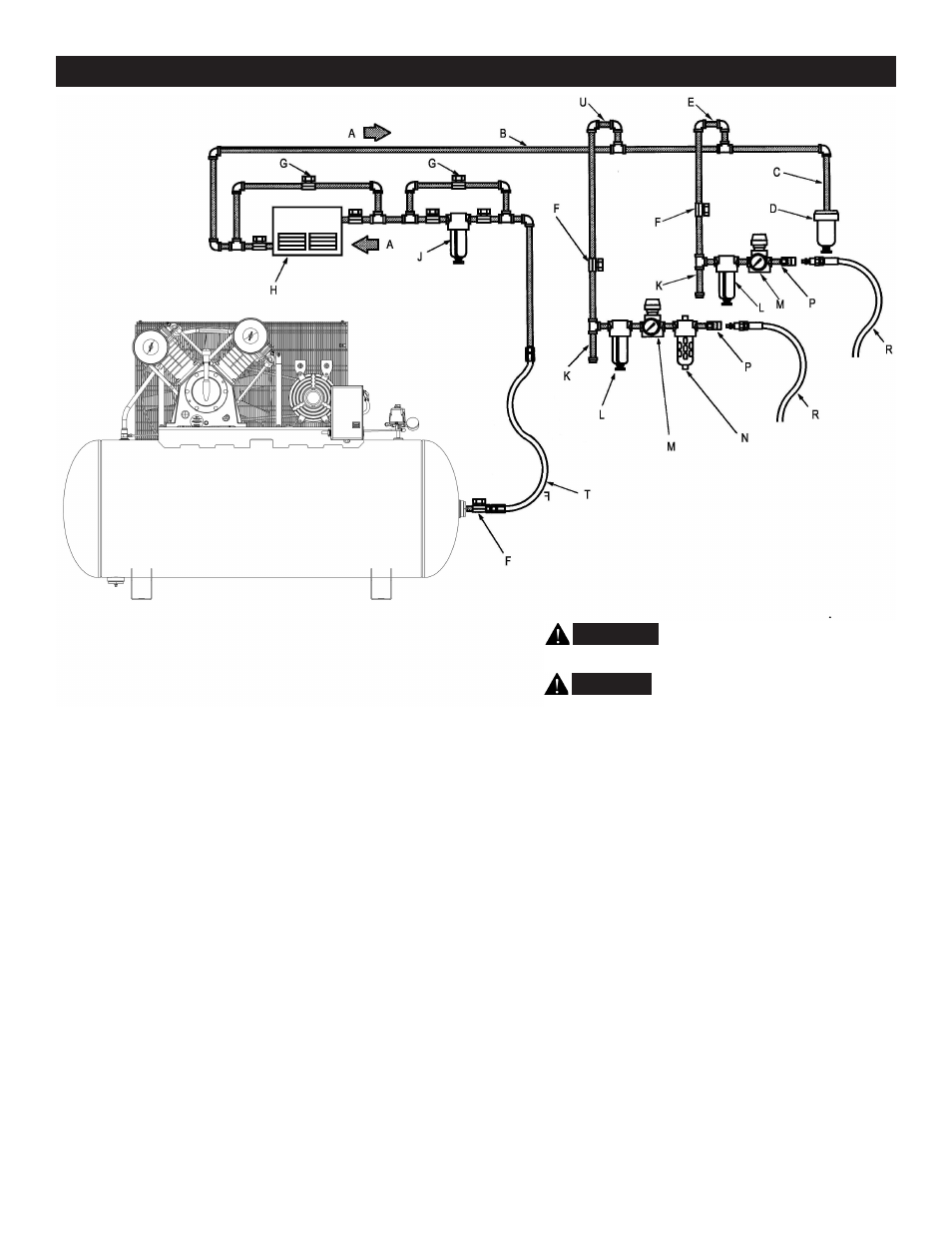

TYPICAL INSTALLATION

Risk of bursting, resulting in injury.

Never use plastic pipe for compressed air.

Never use lubricator for paint spraying

or similar applications.

WARNING:

CAUTION:

Air dryers and after coolers

An air dryer or aftercooler is installed directly in the air line.

Moisture removal and air filtration

As the air cools, moisture will condense in the lines. This

moisture must be removed before it reaches the tool being used.

To remove this moisture, run the main air line downhill to a

moisture trap and drain. Air/water filters should also be installed

in the positions shown.

Air pressure regulation

The air pressure gauge on the pressure switch measures air

pressure inside the tank, not pressure in the air line. Install an air

regulator in the drop line for each tool, to regulate air pressure to

that tool. Never exceed the maximum pressure rating of the tool.

Air lubrication

Install an air lubricator only for those tools requiring

lubrication. Do not use a lubricator for paint spraying or similar

applications. The oil will contaminate the paint and ruin the job.

Shut–off valves

Install shut–off valves in each drop line, to isolate the tool

and its accessories for servicing. You can also install a bypass

line around an accessory.

A

Air flow

B

Feeder line

C

Drain leg

D

Moisture trap with drain

E

Non–lubricated supply line

F

1/4 turn valve

G

Bypass

H

Air dryer or aftercooler

J

Line filter

K

Drip tee with drain

L

Air/water filter with petcock

M

Regulator

N

Lubricator

P

Quick coupler

R

Air hose to tool

T

Flexible air line

U

Lubricated supply line

Compressor may vary from one shown.