Assembly – Powermate IV7518075 User Manual

Page 5

5 - ENG

200-2909

NOTE: These units require a magnetic starter.

Magnetic starters that are not factory mounted on the

compressor can be mounted on the wall if desired. Mount as

close to compressor as possible. Size the wires, protect them with

conduit, and provide branch circuit protection per the National

Electrical Code.

This compressor was shipped with oil in the pump

crankcase. Check oil before operating the air

compressor, see Check Oil under Maintenance.

1. Unpack the air compressor. Inspect the unit for damage. If

the unit has been damaged in transit, contact the carrier

and complete a damage claim. Do this immediately

because there are time limitations to damage claims.

The carton should contain:

•

air compressor

•

operator/parts manual

2. Check the compressor’s serial label to ensure that you

have received the model ordered, and that it has the

required pressure rating for its intended use.

3. Locate the compressor according to the following

guidelines:

a. For optimum performance, locate the compressor close

to the power panel, as specified in ELECTRICAL

POWER REQUIREMENTS, and as close as possible to

the place where the air will be used. This ensures

maximum power to the compressor and maximum air

pressure to the tool.

If both of these conditions

cannot be met, it is better to locate the compressor

close to the power panel, and use a longer air hose

or distribution line to reach the usage area.

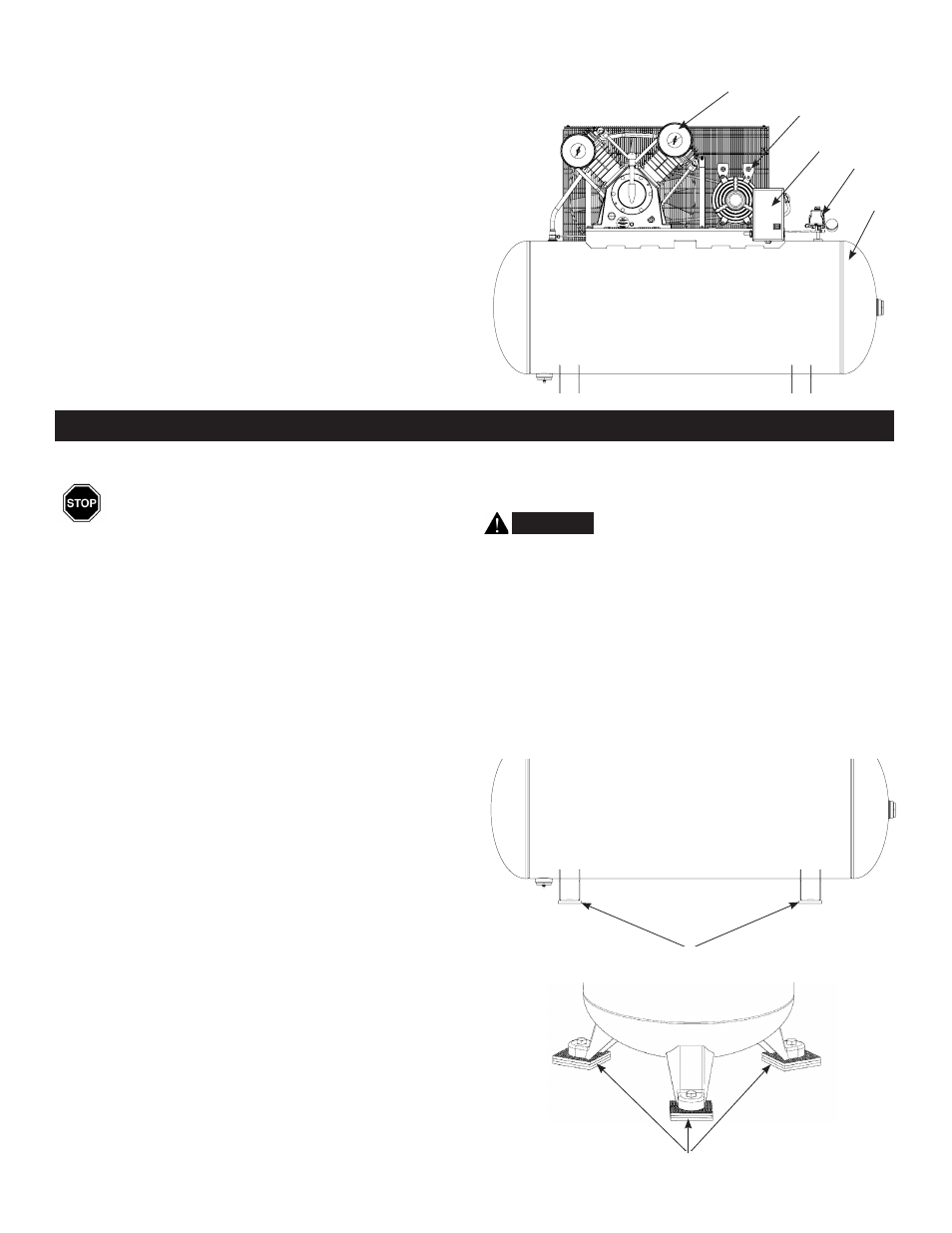

b. The flywheel side of the compressor must be at least

12 inches (31 cm) from any wall or obstruction, in a

clean, well-ventilated area, to ensure sufficient air

flow and cooling.

c. In cold climates, locate the compressor in a

heated building. This will reduce problems with

lubrication, motor starting and freezing of water

condensation.

d. Remove the compressor from the shipping pallet and

place it on the floor or a hard, level surface. The

compressor must be level to ensure proper

lubrication of the pump and good drainage of the

moisture in the tank.

CAUTION:

The shipping pallet is not designed as a

base for an operating compressor. Operating the

compressor while it is on the pallet will void your

warranty.

e.

To prevent damage to tank and pump, the tank must be

shimmed so the pump is level within 1/8” per lineal foot

maximum to distribute oil properly. Fasten to floor and

NEVER force tank feet to floor without shims when

tightening. We also recommend the use of vibration

pads (094-0137) under tank feet (

F).

4. Connect an air hose or distirbution line (not included) to the

compressor.

ASSEMBLY

ASSEMBLING THE COMPRESSOR

Fig. 2

F

Fig. 1

B

D

A

C

E

Fig. 2

F