Maintenance – Powermate PM0558023.01 User Manual

Page 11

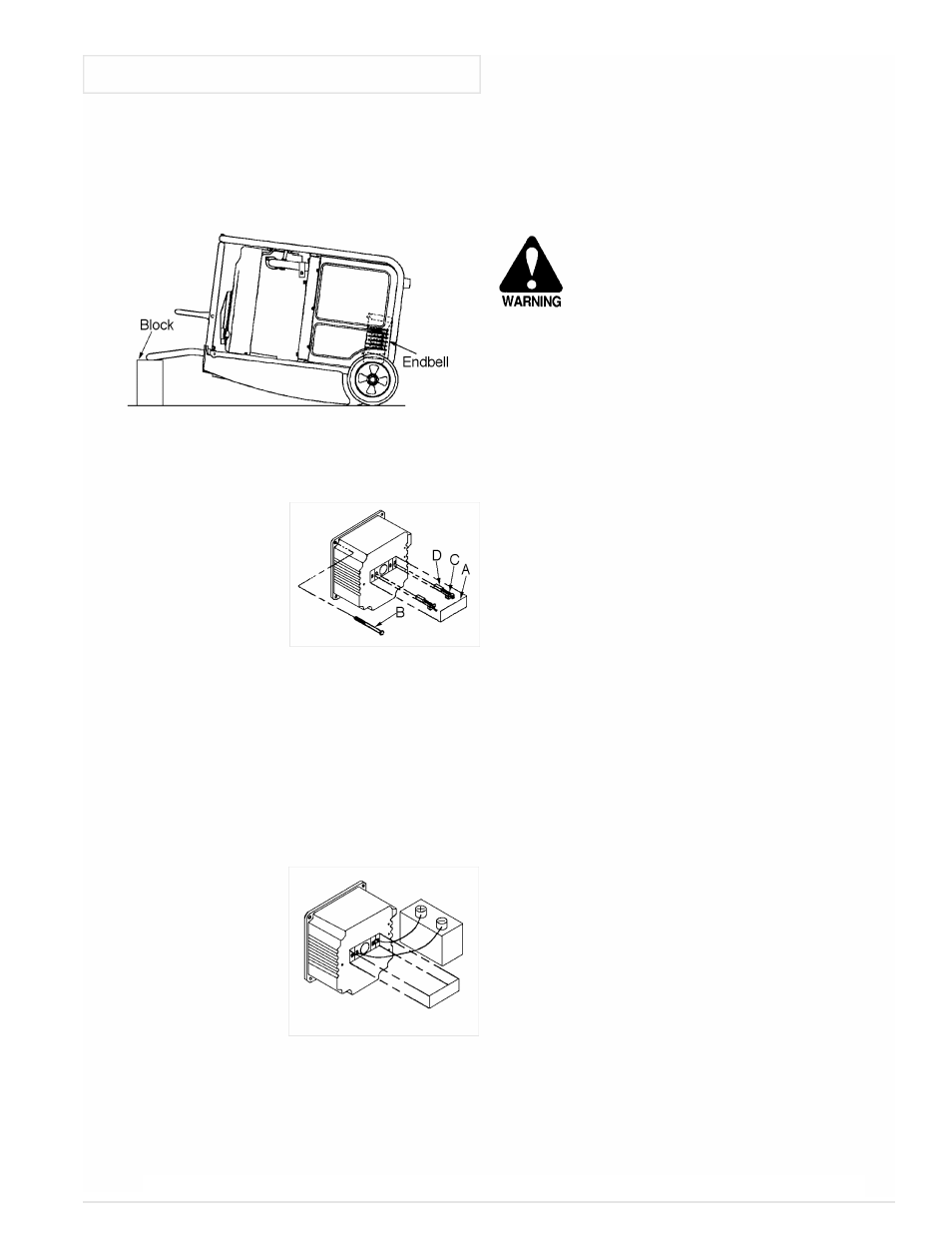

GENERATOR: Brushes

The brushes in the generator should be inspected once

every year for chips and cracks. Brushes should be replaced

when they are worn to 1/4 inch (7mm).

NOTE: Replace brushes in sets only, never separately.

INSPECTING THE BRUSHES

1.

Remove cover plate (A).

2.

Remove 4 stator bolts (B)

and endbell.

3.

Disconnect the green (-) or

blue (+) brush wires from

the tab.

4.

Remove brush mounting

screws (C).

5.

Slide brushes (D) from

holders.

6.

Replace if worn to 1/4 inch (7mm).

7.

Do not over tighten screws.

NOTE: Replace only with brushes specified in parts

list. Other brushes may appear to be identical but may

have completely different mechanical and electrical

characteristics.

EXCITING THE GENERATOR

If there is a loss of residual magnetism (voltage will not

build up), it may be necessary to re-excite the unit.

1.

Use a 6-volt lantern battery

(dry cell).

2.

Remove the brush cover.

3.

Attach the "-" lead of the

battery to the negative

brush. Very briefly, touch

the "+" lead of the battery to

the positive brush as

shown.

4.

Replace the brush cover,

tip the generator to an

upright position and start the engine. Measure output

voltage by using a plug-in voltmeter. If voltage is not

present, turn the engine off and repeat the excitation

procedure.

HEAT SHIELD

Inspect to ensure that all heat shields and heat deflectors

are intact and in place.

ENGINE: Carburetor Icing

During the winter months, rare atmospheric conditions may

develop which will cause an icing condition in the carburetor. If

this develops, the engine may run rough, loose power, and may

stall. This temporary condition can be overcome by deflecting

some of the hot air from the engine over the carburetor area.

WARNING: If a deflector is used, it must be

made of metal.

BATTERY MAINTENANCE

Read all cautions and warnings provided by the battery

manufacturer before doing maintenance on your battery.

For Batteries with Filler Openings: Check battery fluid

level by removing the filler caps. If necessary, fill the battery

with distilled water to the indicator fill level only.

Use a terminal post brush to clean the battery terminal

posts and terminals. Good, clean terminals are necessary for

good contact.

ENGINE MAINTENANCE

NOTE: Refer to the engine manufacturer's manual for

service and maintenance of the engine.

MAINTENANCE

11

English

Tip unit as shown to access the endbell.

Place a block under the handle to prevent

damage to the fuel tank.