Operation, Setting up and making a flux-cored weld – Lincoln Electric IMT10135 WIRE FEEDER WELDER 180 User Manual

Page 12

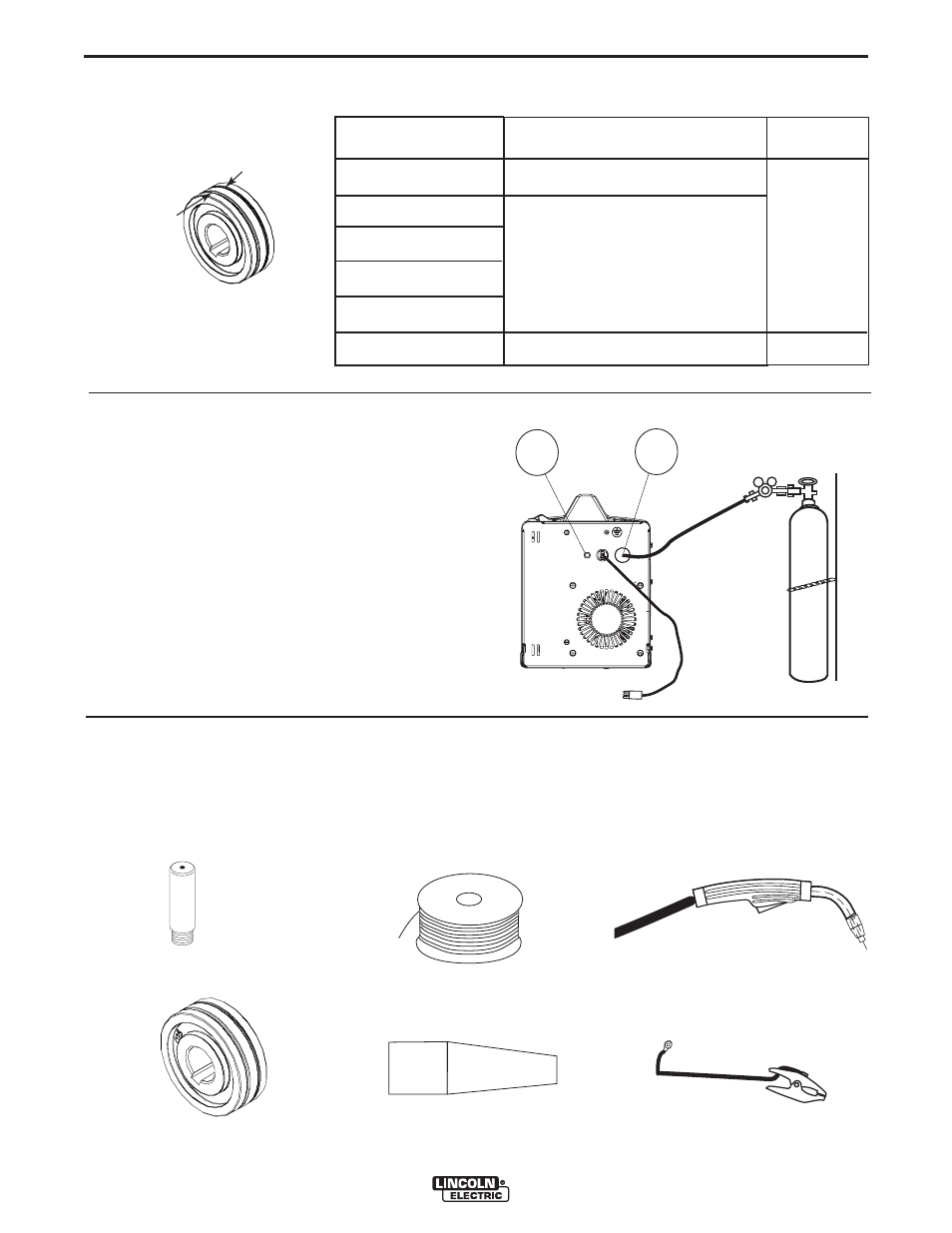

A. ITEMS NEEDED FOR

FLUX CORED WELDING

1. .035”(0.9mm) Contact Tip

2. Dual Groove Drive Roll.

3. .035”(0.9mm) NR-211MP Flux-

Cored Wire

4. Black Flux Cored gun nozzle

5. Welding Gun

6. Work Cable & Clamp

.035

.035 NR-211 MP

FLUX-CORED WIR

E

SETTING UP AND MAKING A FLUX-CORED WELD

B-4

OPERATION

B-4

WIRE FEEDER WELDER (180 MODEL)

TABLE B.1

DRIVE ROLLS

Wire Diameter & Type

.025”(0.6mm) MIG wire

.030”(0.8mm) MIG wire

.035”(0.9mm) MIG wire

.030”(0.8mm) flux-cored

.035”(0.9mm) flux-cored

.045”(1.1mm) flux-cored

Smooth Drive Roll

(Dual Grooves)

Use .025”(0.6mm) Drive Roll Groove

Use .035”(0.9mm) Drive Roll Groove

Use .045”(1.1mm) Drive Roll Groove

Drive Roll

Part Number

KP2948-1

KP3285-1*

See Figure B.6

12. CIRCUIT BREAKER – If the rated input current of

the machine is exceeded this circuit breaker will trip.

Press to reset.

13. GAS INLET – Shielding gas connects to this inlet.

12

13

FIGURE B.6

.0

25

.025 GROOVE*

.035 GROOVE*

*KP3285-1 May also be used to feed .030”(0.8mm) and .035”(0.9mm) flux-cored wire.

- Invertec V310-T DC (2 pages)

- VANTAGE 500 (CE) 11575 (50 pages)

- INVERTEC V350-PRO SVM152-A (155 pages)

- IMVERTEC V160-T (36 pages)

- IDEALARC CV-300 (112 pages)

- INVERTEC POWER WAVE 450 SVM112-B (293 pages)

- AUTO-DARKENING HELMET IM10001 (12 pages)

- IM10111 IDEALARC R3R-500-I (28 pages)

- IM10110 IDEALARC R3R-400 (25 pages)

- IM10051 INVERTEC V311-T AC_DC (38 pages)

- IM10059 SQUARE WAVE TIG 175 (30 pages)

- IM10096 POWER MIG 256 (37 pages)

- IM10096 POWER MIG 256 (38 pages)

- IM10105 POWER MIG 350MP (47 pages)

- IM10115 FLEXTEC 650 (42 pages)

- IM10132 FLEXTEC 650 (56 pages)

- IM10132 FLEXTEC 650 (36 pages)

- IM10018 IDEALARC DC-600 VRD (55 pages)

- IM10107 IDEALARC DC-400 (40 pages)

- IM10062 FLEXTEC 450 (72 pages)

- IM10091 FLEXTEC 450 CE (40 pages)

- IM10094 RED-D-ARC FX450 (31 pages)

- IM10157 12_24V 10A Auto HF Household Charger (16 pages)

- IM10139 JUMP STARTER (12 pages)

- IM10149 POWER WAVE ADVANCED MODULE (46 pages)

- IM10102 AIR VANTAGE 650 (60 pages)

- IM10103 AIR VANTAGE 700 (AU) (57 pages)

- IM10065 AIR VANTAGE 500 CUMMINS (54 pages)

- IM10066 AIR VANTAGE 500 (AU) (56 pages)

- IM10041 VANTAGE 500 CUMMINS (56 pages)

- IM10128 AIR VANTAGE 500 KUBOTA (AU) (56 pages)

- IM10090 ARC TRACKER (48 pages)

- IM10147 AUTO-DARKENING HELMET (12 pages)

- IM10087 AutoDrive 19 CONTROLLER (28 pages)

- IM10125 AutoDrive 19 TANDEM (34 pages)

- IM10069 AutoDrive 4R100 (32 pages)

- IM10145 AUTOPRO 20 (24 pages)

- IM10025 BIG RED 500 (40 pages)

- IM10019 BIG RED 600 (41 pages)

- IM10005 BULLDOG 140 (46 pages)

- IM10074 BULLDOG 5500 (56 pages)

- IM10067 CENTURY AC120 (20 pages)

- IM10109 CIRCULATOR (33 pages)

- IM10109 CIRCULATOR (36 pages)

- IM10153 CLASSIC 300 HE (60 pages)