Operation, Opera t or ʼs manual – Lincoln Electric IMT10135 WIRE FEEDER WELDER 180 User Manual

Page 11

OPERA

T

OR

ʼS

MANUAL

B-3

OPERATION

B-3

WIRE FEEDER WELDER (180 MODEL)

See Figure B.3

8. WELDING GUN CONNECTOR BUSHING &

THUMBSCREW – Provides electrical power to the

welding gun. The thumbscrew holds the welding

gun into the connector block. (Front Cover and Side

Door have been removed for clarity of Items 8 and

9).

9. OUTPUT TERMINALS - Connections to these ter-

minals determines the welding polarity, depending

on whether the process being used is flux-cored

welding or MIG welding.

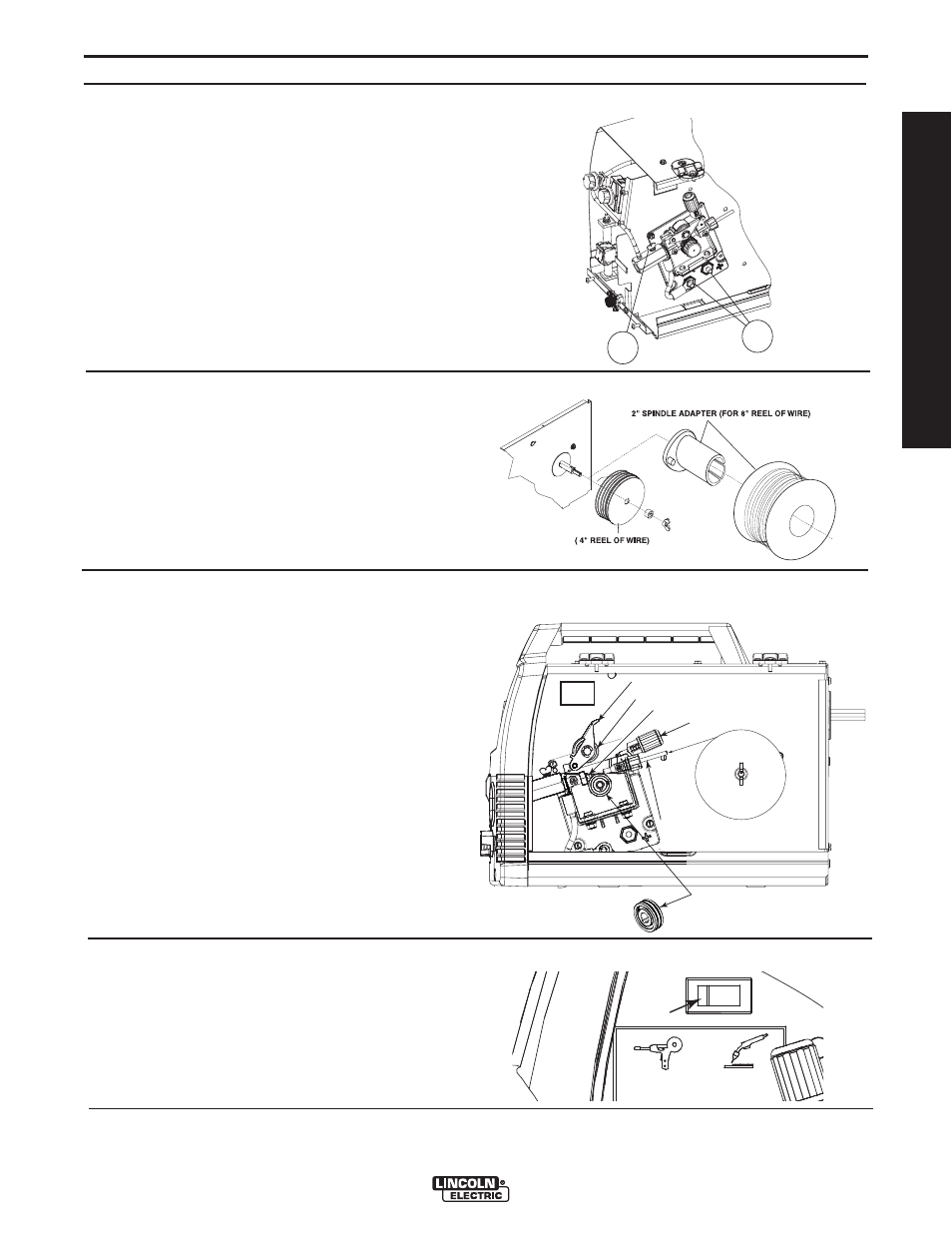

See Figure B.4

10. WIRE SPOOL SPINDLE AND BRAKE – Holds a

4”(102mm) diameter spool. Use the 2”(51mm)

spindle adapter included with the machine for

8”(203mm) diameter spools. The wing nut sets

the brake friction to prevent the spool from over

rotating when the trigger is released. Tightening

the wing nut will prevent the spool from rotating

when the trigger is released.

See Figure B.5

11. WIRE DRIVE & COMPONENTS – Feeds wire

from the wire spool through the drive and through

the welding gun to the work piece.

a. Drive Roll – Drives the wire through the drive

system. The drive roll has grooves to match the

specific wire type and diameter. Refer to Table

B.1 for available drive rolls.

b. Incoming & Outgoing Guide – The wire is fed

through both guides. The Pivot Arm Assembly,

Tension Arm Assembly and Drive Roll keep

pressure on the wire in the groove.

c. Tension Arm Assembly – Turning clockwise

increases the forward force on the wire and turn-

ing counterclockwise decreases the force.

8

9

FIGURE B.3

FIGURE B.4

FIGURE B.5

FIGURE B.5a

WIRE SPOOL

.035" (0.9mm)

NR-211-MP

DRIVE ROLL

PIVOT ARM ASSEMBLY

TENSION ARM ASSEMBLY

OUTGOING GUIDE

INCOMING GUIDE

BEARING

See Figure B.5a

Magnum 100SG / Magnum 100L Switch - The

Magnum 100SG Spool Gun can be purchased at

authorized retailers. The part number is K2532-1.

MAGNUM 100SG

SWITCH

MAGNUM 100L