Warning – Lincoln Electric IMT10004 (4X5) SHADE 10 HELMET User Manual

Page 4

OPERATING INSTRUCTIONS

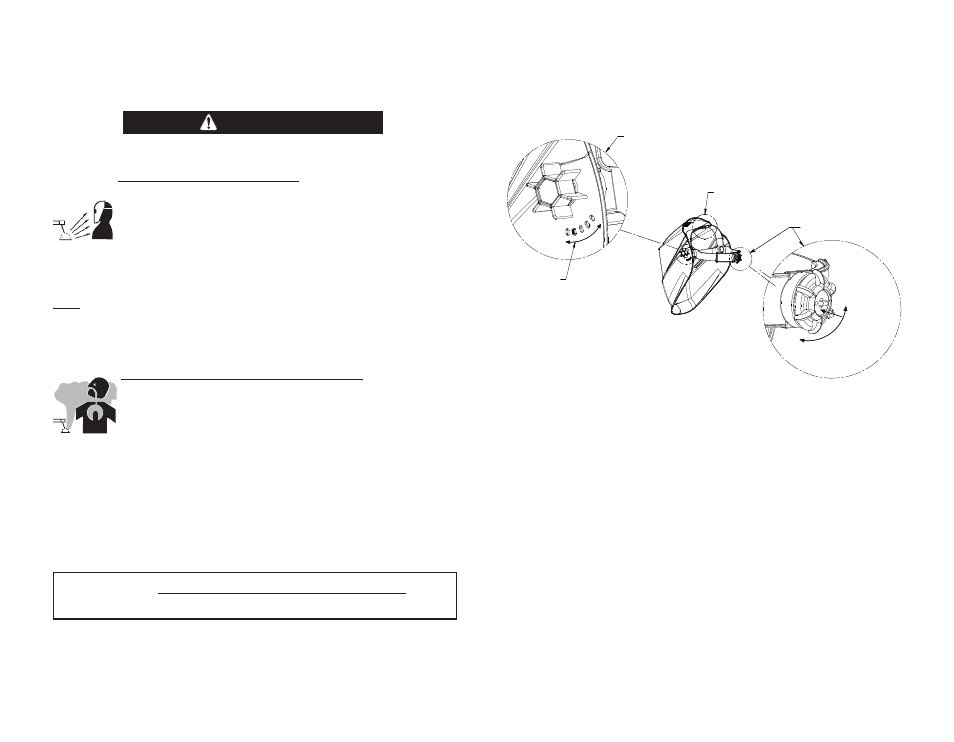

Headgear Adjustment

Head Size Adjustment:

Headband tightness is adjusted by pushing in the

ratchet knob and turning to adjust to desired comfort level.

This knob is

located at the back of the helmet. HEAD GEAR CROWN ADJUSTMENT is

made by adjusting crown strap for vertical placement on the head and snap-

ping the pin into the hole to lock securely in place.

Tilt: Tilt is adjusted on the left side of the helmet. TILT is adjusted by loos-

ening outside tension knob and releasing the adjustment lever from its cur-

rent location and moving it to another location. Retighten the outside tension

knob when finished.

2

CROWN

ADJUSTMENT

TILT ADJUSTMENT

RATCHET KNOB

PIN HOLES FOR

ADJUSTMENT

SAFETY WARNINGS – READ BEFORE USING

ARC Rays can injure eyes and burn skin

• Before welding, always inspect helmet and filter lens to be sure they are fitted

properly, in good condition and not damaged.

• Check to see that the clear lens is clean and securely attached to the helmet.

• Always wear safety glasses or goggles under the welding helmet and protective

clothing to protect your skin from radiation, burns and spatter.

• Ensure that optical radiation from other welder’s arcs in the immediate area

does not enter in from behind the helmet and auto-darkening filter.

Note: Auto-darkening filters in Lincoln helmets are designed to protect the user against harmful

ultra-violet and infrared rays both in the dark and light states. No matter what shade the filter is

set to, the UV/IR protection is always present.

FUMES AND GASES can be dangerous to your health.

• Keep your head out of fumes.

• Use enough ventilation or exhaust at the arc or both to keep fumes and gases

from your breathing zone and general area.

• When welding with electrodes which require special ventilation such as

stainless or hard facing (see instructions on container or MSDS) or on

lead or cadmium plated steel and other metals or coatings which pro-

duce highly toxic fumes, keep exposure as low as possible and within

applicable OSHA PEL and ACGIH TLV limits using local exhaust or

mechanical ventilation. In confined spaces or in some circumstances,

outdoors, a respirator may be required. Additional precautions are also

required when welding on galvanized steel.

1

WARNING

Refer to http://www.lincolnelectric.com/safety

for additional safety information.