Operation, Setting up and making a flux-cored weld, Drive roll and wire guides – Lincoln Electric IMT10106 POWER MIG 180 DUAL User Manual

Page 12

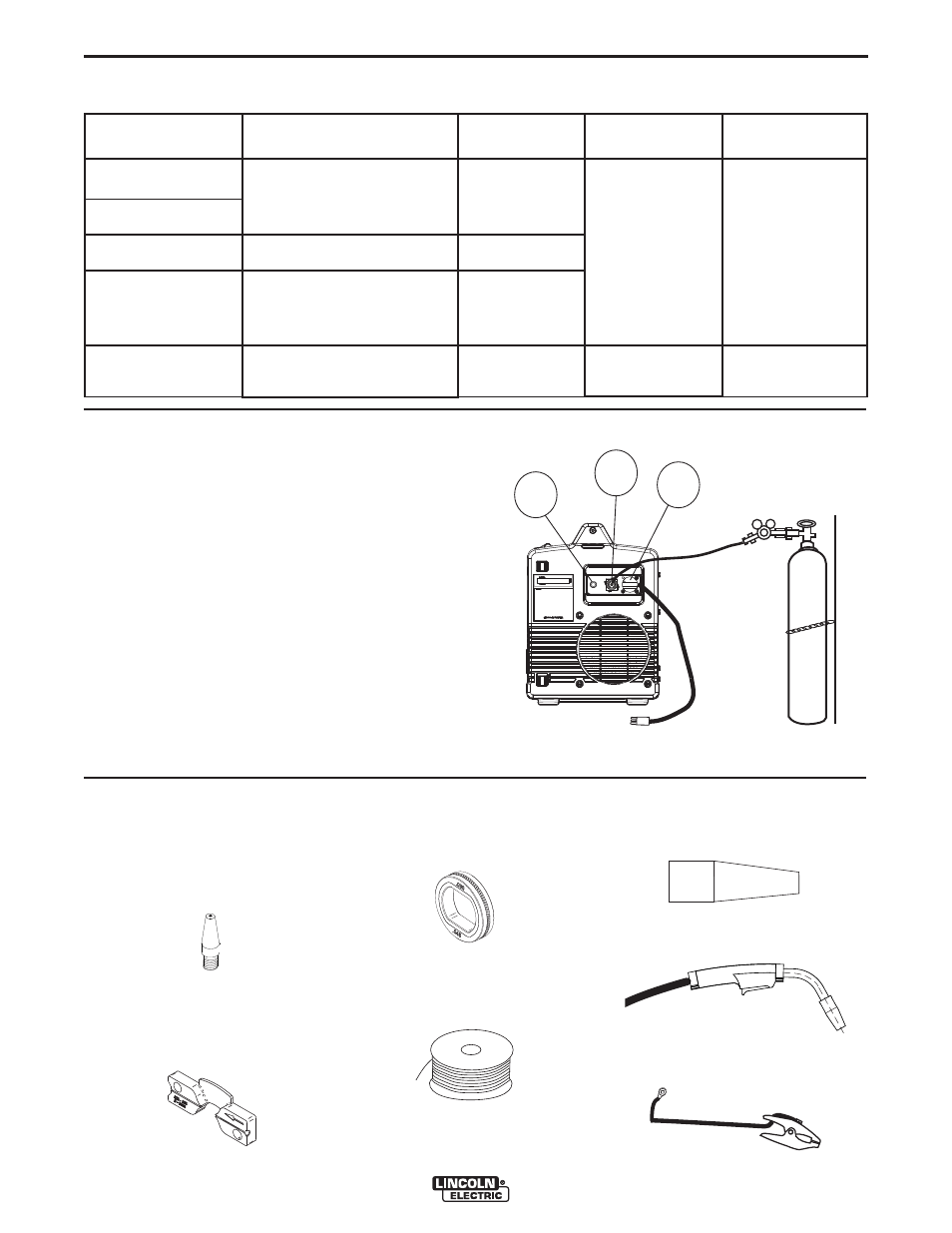

A. ITEMS NEEDED FOR

FLUX CORED WELDING

1. 035”(0.9mm) Contact Tip

2. .025”-.035”(0.6mm-0.9mm) wire

guide

3. Knurled Drive Roll

4. .035”(0.9mm) NR-211MP Flux-

Cored Wire

5. Black Flux Cored gun nozzle

6. Welding Gun

7. Work Cable & Clamp

.035

.035 NR-211 MP

FLUX-CORED WIR

E

SETTING UP AND MAKING A FLUX-CORED WELD

B-4

OPERATION

B-4

POWER MIG® 180 DUAL

(See Figure B.6 for the following Items.)

12. CIRCUIT BREAKER – If the rated input current of

the machine is exceeded this circuit breaker will

trip. Press to reset.

13. GAS INLET – Shielding gas connects to this inlet.

14. POWER CORD CONNECTION - Ensure power

cord is diconnected from input voltage supply prior

to connecting or removing the cord from the

machine. Connect the circular connector present

on either input cord (120V or 230V) to the recepta-

cle on the back of the machine. The power cord

connector is secured to the receptacle by rotating

the connectorʼs coupling ring clockwise, until the

coupling ring latches on to the receptacle. Use

only the appropriate (120V or 230V) power cords

supplied by the Lincoln Electric Company.

12

13

14

FIGURE B.6

TABLE B.1

DRIVE ROLL AND WIRE GUIDES

Wire Diameter &

Type

.025”(0.6mm) MIG wire

.030”(0.8mm) MIG wire

.035”(0.9mm) MIG wire

.030”(0.8mm) flux-cored

.035”(0.9mm) flux-cored

.045”(1.1mm) flux-cored

Drive Roll

.025”/.030” (0.6mm/0.8mm)

Smooth Drive Roll

.035”(0.9mm) Smooth Drive Roll

.030”/.045” (0.8mm/1.1mm)

Knurled Drive Roll

.030”/.045” (0.8mm/1.1mm)

Knurled Drive Roll

Inner Wire Guide

.025”-.035”

(0.6mm-0.9mm)

Steel Wire Guide

.045”(1.1mm) Steel

Wire Guide

Inner Wire Guide

Part Number

KP2531-1

KP2531-2

Drive Roll Part

Number

KP2529-1

KP2529-2

KP2529-3

KP2529-3

INNER WIRE GUIDE

.025-.035 (.6-.9mm)