Operation – Lincoln Electric IM10053 RANGER 305 D (AU) User Manual

Page 22

RANGER® 305D (AU)

B-7

OPERATION

B-7

Ranger® 305D (AU) settings when using the K930-2

TIG Module with an Amptrol or Arc Start Switch:

• Set the MODE Switch to the TOUCH START TIG

setting.

• Set the "IDLER" Switch to the "AUTO" position.

• Set the "WELDING TERMINALS" switch to the

"REMOTELY CONTROLLED" position. This will keep

the "Solid State" contactor open and provide a "cold"

electrode until the Amptrol or Arc Start Switch is

pressed.

When using the TIG Module, the OUTPUT control on

the Ranger® 305D (AU) is used to set the maximum

range of the CURRENT CONTROL on the TIG Module

or an Amptrol if connected to the TIG Module.

WIRE WELDING-CV

Connect a wire feeder to the Ranger® 305D (AU)

according to the instructions in INSTALLATION

INSTRUCTIONS Section.

The Ranger® 305D (AU) in the CV-WIRE mode, per-

mits it to be used with a broad range of flux cored wire

(Innershield and Outershield) electrodes and solid wires

for MIG welding (gas metal arc welding). Welding can

be finely tuned using the ARC CONTROL. Turning the

ARC CONTROL clockwise from –10 (soft) to +10 (crisp)

changes the arc from soft and washed-in to crisp and

narrow. It acts as an inductance/pinch control. The

proper setting depends on the procedure and operator

preference. Start with the dial set at 0.

Listed below are some wires suitable for use on this

machine:

• Innershield - NR-311, NS-3M, NR-207, NR-203 Ni 1%,

NR-212.

• Outershield - 0S-70, 0S-71M, 0S-71 ELITE.

• Solid wires for MIG welding - .035 (0.9 mm), and

.045 (1.1 mm), Super Arc L-50 and L-56, .035 (0.9 mm)

and

.045 (1.1 mm) Blue Max MIG 308 LS.

Contact your local authorized Lincoln Electric Distributor

or the Lincoln Electric Company for specific wires used

on certain applications with this machine.

ARC GOUGING

The Ranger® 305D (AU) can be used for limited arc

gouging. For optimal performance, set the MODE

switch to CC-STICK and the ARC CONTROL to +10.

Set the OUTPUT CONTROL knob to adjust output

current to the desired level for the gouging electrode

being used according to the ratings in the following

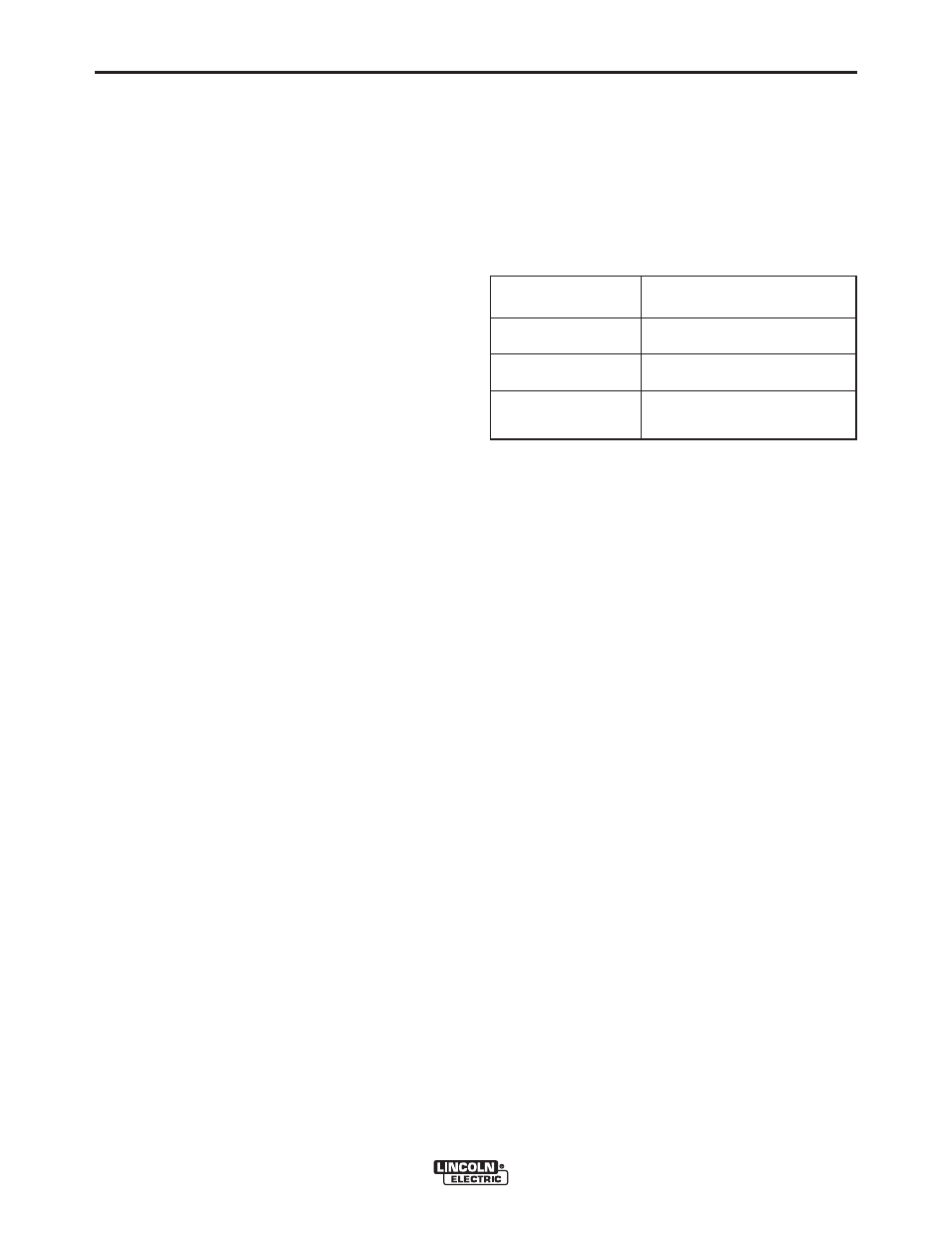

Table.

Carbon Diameter

Current Range (DC, electrode

positive)

1/8"

60-90 Amps

5/32"

90-150 Amps

3/16"

200-250 Amps