Panther™ push pull gun - operating instructions, Drive roll groove selection – Lincoln Electric IM10033 PANTHER K2874-1, K2874-2, K2874-3, K2875-2 User Manual

Page 13

PANTHER™ Push Pull Gun - OPERATING INSTRUCTIONS

6

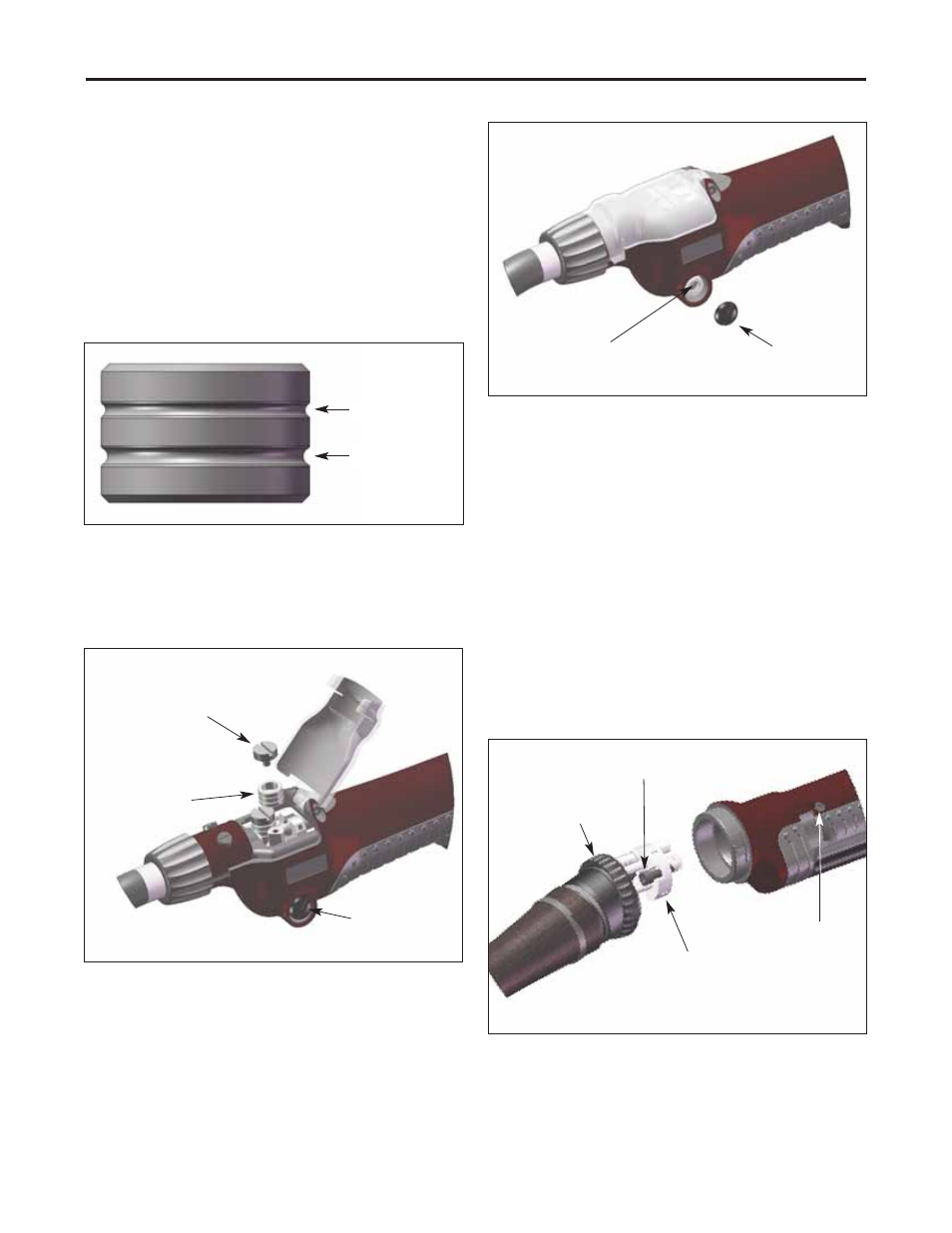

Drive Roll Groove Selection

The drive rolls have two grooves. A wider groove for feeding

3/64” (1.2mm) wire and a narrow groove for feeding .035”

(0.9mm) wire to accommodate changes in the wire size used.

Changing between the grooves simply requires reversing the

drive roll.

A. Drive Roll Orientation

1. Drive rolls are scribed with wire groove size. For appropri-

ate groove orientation, ensure desired size callout is facing

up and visible.

B. Changing Drive Rolls

1. Flip lid open

2. Unscrew thumb screw and remove drive roll. Pressure may

have to be applied to drive roll tension access cover.

D. Cable Assembly Removal

1. Split leather cable cover at velcro opening approximately

24" (60.96cm) from strain relief.

2. Turn strain relief locking ring counter-clock-wise and slide

down cable assembly approximately 24" (60.96cm).

3. Loosen rear handle screw and pull back ball joint strain

relief to access connections.

4. Disconnect black 8-position electrical connector between

handle and cable assembly - cut off safety connection wire,

then disconnect connector (safety wire can be .035 or 3/64"

aluminum wire).

5. Loosen (2) cable assembly front block retaining screws.

6. Pull cable assembly from rear of gun, assuring not to snag

the 8-pin electrical connector.

DRIVE ROLL

RETAINING

THUMB SCREW

DRIVE ROLL

DRIVE ROLL

TENSION

ACCESS COVER

DRIVE ROLL

TENSION

ACCESS COVER

DRIVE ROLL

TENSION

ADJUSTING

SCREW

STRAIN RELIEF

LOCKING RING

RETAINING

SCREWS (2x)

HANDLE

SCREW

CABLE

ASSEMBLY

FRONT BLOCK

.035"

3/64"

C. Drive Roll Tension Adjustment

NOTE: Drive roll tension is factory set and does not typi-

cally require adjustment. Over-tightening tension can result

in distortion of welding wire.

1. Unscrew drive roll tension access cover.

2. Using M4 allen wrench supplied in tool kit, rotate drive roll

tension adjustment screw clockwise to increase tension,

counter-clock-wise to descrease tension.

NOTE: Make sure to lubricate o-rings before installing cable.