General description – Lincoln Electric IM10168 K3355-,K3356-,K3357-,K3358- MAGNUM PRO AL Push Pull Gun User Manual

Page 11

B - 1

OPERATION

MAGNUM

®

PRO AL Gun

GENERAL DESCRIPTION

The Lincoln Electric Magnum

®

Pro

AL Gun

gun maintains a

constant, steady, uniform wire feed speed. The constant push

exerted by the motor in the cabinet, combined with the pull of the

the wire conduit. The 24VDC gun motor is controlled by a three

and three-quarter (3 3/4) turn potentiometer in the gun handle.

CONTROLS AND SETTINGS

Potentiometer:

• The laterally-positioned potentiometer is located in the gun

body, providing up to 800 ipm with 3 3/4 turns.

Micro Switch:

• The micro switch assembly consists of the micro switch, and

leads.

Trigger Sensitivity:

• The amount of trigger level travel can be shortened for a

"quicker" or "more responsive" action.

• A more sensitive trigger lever is produced by reducing the

gap between the trigger lever and the micro switch lever.

• By turning-in the Trigger Sensitivity Adjustment Screw, it

closes the gap between the trigger lever and the micro switch

lever - this enables the operator to increase the sensitivity of

the trigger lever.

Sensitivity Adjustment:

• With the wire feeder turned on (with or without welding wire

loaded), turn the screw in until the micro switch is activated.

• Once activated, the gun and wire feeder motors will begin

feeding wire.

• Retract the screw accordingly until the system is deactivated

and adjusted to the operators' liking.

DRIVE ROLL AND IDLER ROLLS

Drive Roll Installation and Removal:

NOTE: Neither of the handles needs to be removed to access

the Drive or Idler Rolls.

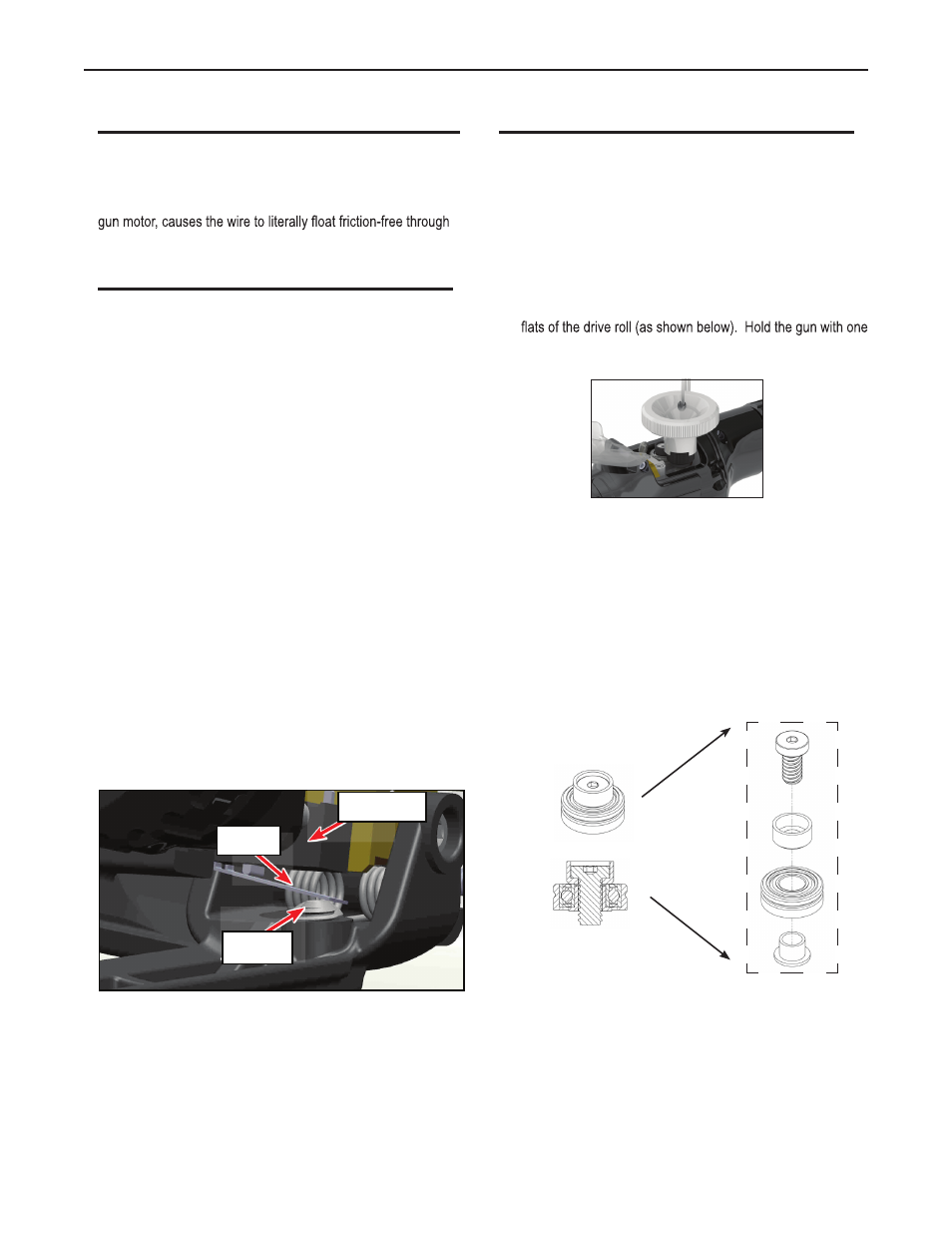

1. Pull the Cam Lever away from the idler roll. This will relieve

the pressure against the drive roll.

2. Align the Drive Roll Removal Tool (P/N K3987-1) over the

hand or on a table top, with the other hand give the Removal

Tool a quick snap-turn in the CLOCKWISE DIRECTION.

3. Once the drive roll is loose, continue to spin drive roll in the

clockwise direction to remove the drive roll from the gun.

4. Install a new drive roll on the left-hand threaded shaft. The

drive roll will self-tighten when it is feeding wire.

Idler Roll Installation and Removal:

Please use the following drawing as a guide when needing to

reassemble prior to installing into the welding gun.

Screw adjusted out of trigger, pre-setting the micro switch lever for

shorter trigger motion sensitivity.

Set Screw

Lever

Micro Switch