Shade guide, Warning, Lens replacement – Lincoln Electric IM10000 Cool-Shield Helmet User Manual

Page 7

SHADE GUIDE:

If your helmet does not include any one of the shades referenced above, it is

recommended you use the next darker shade.

• DO NOT WELD WITH A DAMAGED OR DEFECTIVE LENS, i.e.

cracked, pitted, etc.

ALWAYS TEST TO BE SURE THE ADF CARTRIDGE IS CHARGED

BEFORE WELDING. The helmet can be placed in sunlight to charge. Do not

store the helmet in a dark cabinet or other storage area for extended periods.

While welding the Arc also charges the ADF cartridge.

5

WARNING

GUIDE FOR SHADE NUMBERS

OPERATION

ELECTRODE SIZE

ARC

MINIMUM

SUGGESTED(1)

1/32 in. (mm)

CURRENT (A)

PROTECTIVE

SHADE NO.

SHADE

(COMFORT)

Shielded metal arc

Less than 3 (2.5)

Less than 60

7

–

welding

3-5 (2.5–4)

60-160

8

10

5-8 (4–6.4)

160-250

10

12

More than 8 (6.4)

250-550

11

14

Gas metal arc

Less than 60

7

–

welding and flux

60-160

10

11

cored arc welding

160-250

10

12

250-500

10

14

Gas tungsten arc

Less than 50

8

10

welding

50-150

8

12

150-500

10

14

Air carbon

(Light)

Less than 500

10

12

Arc cutting

(Heavy)

500-1000

11

14

Plasma arc welding

Less than 20

6

6 to 8

20-100

8

10

100-400

10

12

400-800

11

14

Plasma arc cutting

(Light)

(2)

(2)

(2)

Less than 300

8

9

(Medium)

300-400

9

12

(Heavy)

400-800

10

14

Torch brazing

–

–

3 or 4

Torch soldering

–

–

2

Carbon arc welding

–

–

14

PLATE THICKNESS

in.

mm

Gas welding

Light

Under 1/8

Under 3.2

4 or 5

Medium

1/8 to 1/2

3.2 to 12.7

5 or 6

Heavy

Over 1/2

Over 12.7

6 or 8

Oxygen cutting

Light

Under 1

Under 25

3 or 4

Medium

1 to 6

25 to 150

4 or 5

Heavy

Over 6

Over 150

5 or 6

(1)

As a rule of thumb, start with a shade that is too dark, then go to a lighter shade which gives sufficient view of the weld zone without going

below the minimum. In oxyfuel gas welding or cutting where the torch produces a high yellow light, it is desirable to use a filter lens that absorbs

the yellow or sodium line the visible light of the (spectrum) operation

(2)

These values apply where the actual arc is clearly seen. Experience has shown that lighter filters may be used when the arc is hidden by the

workpiece.

.

Data from ANSI Z49.1-2005

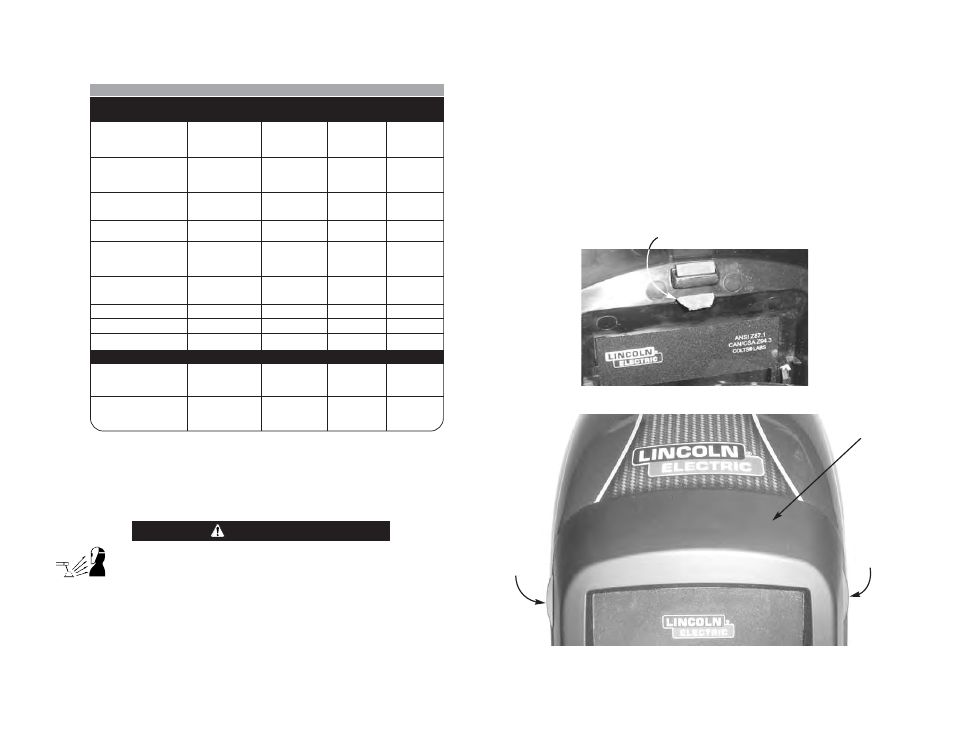

LENS REPLACEMENT

Outside Protective Cover Lens Replacement:

Press down on the Tab inside the top of the helmet while also pressing in on

the Finger Tabs on both sides of the bezel piece on the front of the helmet.

Pull the bezel outward to remove. Remove the polycarbonate protective

lens. Place the new polycarbonate lens in the recessed lens area. Be sure

the cover lens is properly seated. Then, simply insert the lower tabs of the

bezel back into the helmet shell and rotate up, snapping the bezel into place.

Ensure all three tabs have been correctly snapped in. Never use the Auto-

Darkening FILTER without the inside and outside cover lens properly

installed.

Lens Removal

6

OUTSIDE

TAB

OUTSIDE

TAB

BEZEL

INSIDE TAB