Troubleshooting, Caution – Lincoln Electric IM10115 FLEXTEC 650 User Manual

Page 33

E-2

TROUBLESHOOTING

E-2

FLEXTEC™ 650

Observe all Safety Guidelines detailed throughout this manual

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

CAUTION

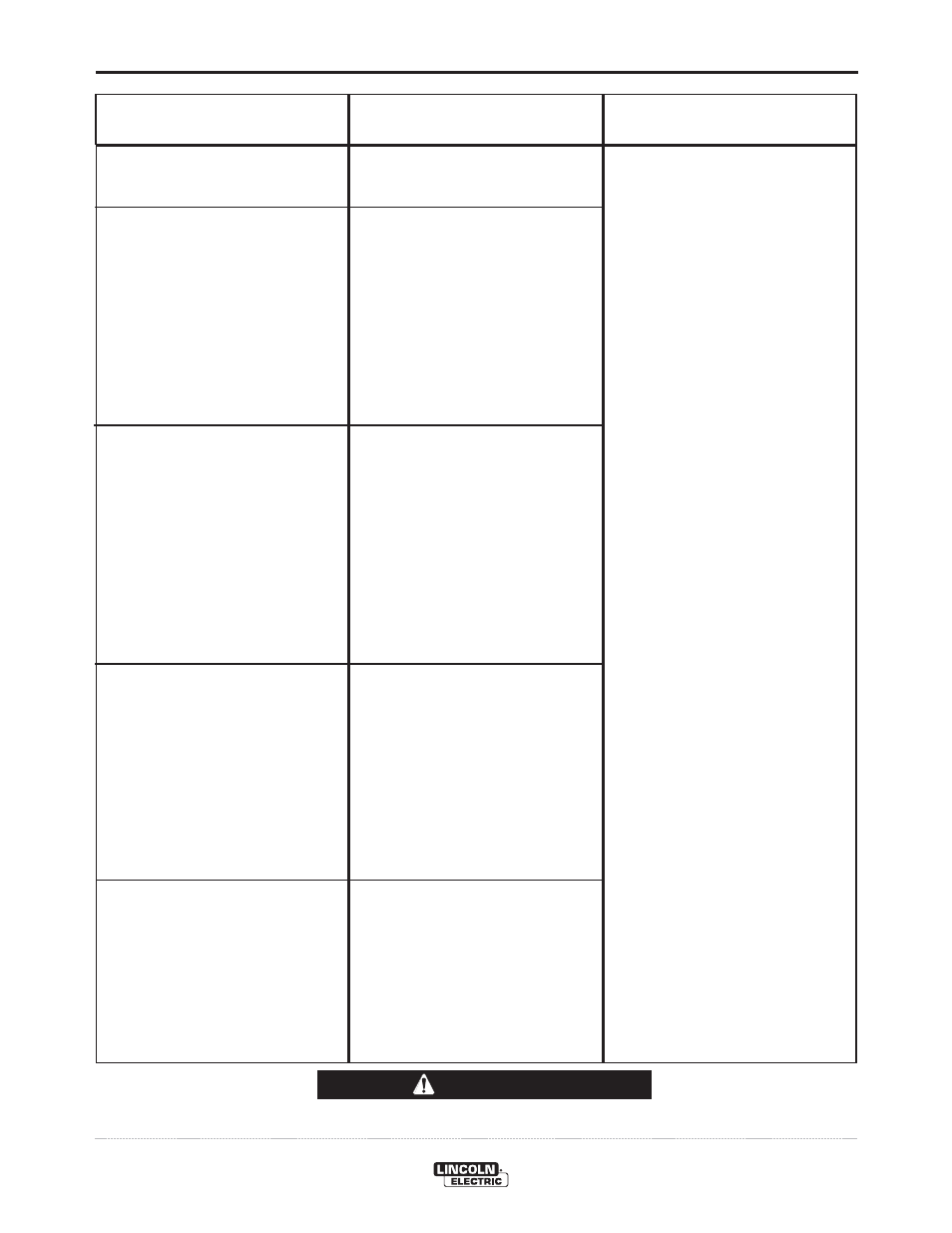

PROBLEMS

(SYMPTOMS)

POSSIBLE

CAUSE

RECOMMENDED

COURSE OF ACTION

Major physical or electrical damage

is evident when the sheet metal

covers are removed.

Machine wonʼt weld, canʼt get any

output.

Thermal LED is lit.

Wire feeder wonʼt work. Apparently

no power to wire feeder

1. Contact your local authorized

Lincoln Electric Field Service facil-

ity for technical assistance.

1. If the displays show an Err ###

see the fault section for corrective

action.

2 If the thermal LED is lit refer to the

thermal section.

3 If the output terminals are in

remote control switch to "ON" and

check for output voltage. If output

voltage is now present check for

correct remote control connection

and operation.

1. Check for proper fan operation.

• Check for material blocking

intake or exhaust louvers.

• Blow air in the rear louvers to

clear dirt from the fan.

Note: The Fan As Needed circuitry

automatically shuts off the fan

5 minutes after welding has

stopped.

2. Welding output ratings may have

been exceeded. Allow the

machine to cool down and reset.

1. Check the 115/42V wire feeder

switch (located on the case front)

to make sure it is properly set for

the input voltage requirement of

the wire feeder.

2. Check circuit breakers by the wire

feeder receptacles on the front of

the machine. Reset if required.

3. Check the control cable between

the power source and the wire

feeder for continuity.

1.If all recommended possible areas

of misadjustment have been

checked and the problem persists,

Contact your local Lincoln

Authorized Field Service

Facility.