Installation – Lincoln Electric IM10115 FLEXTEC 650 User Manual

Page 13

A-6

INSTALLATION

FLEXTEC™ 650

A-6

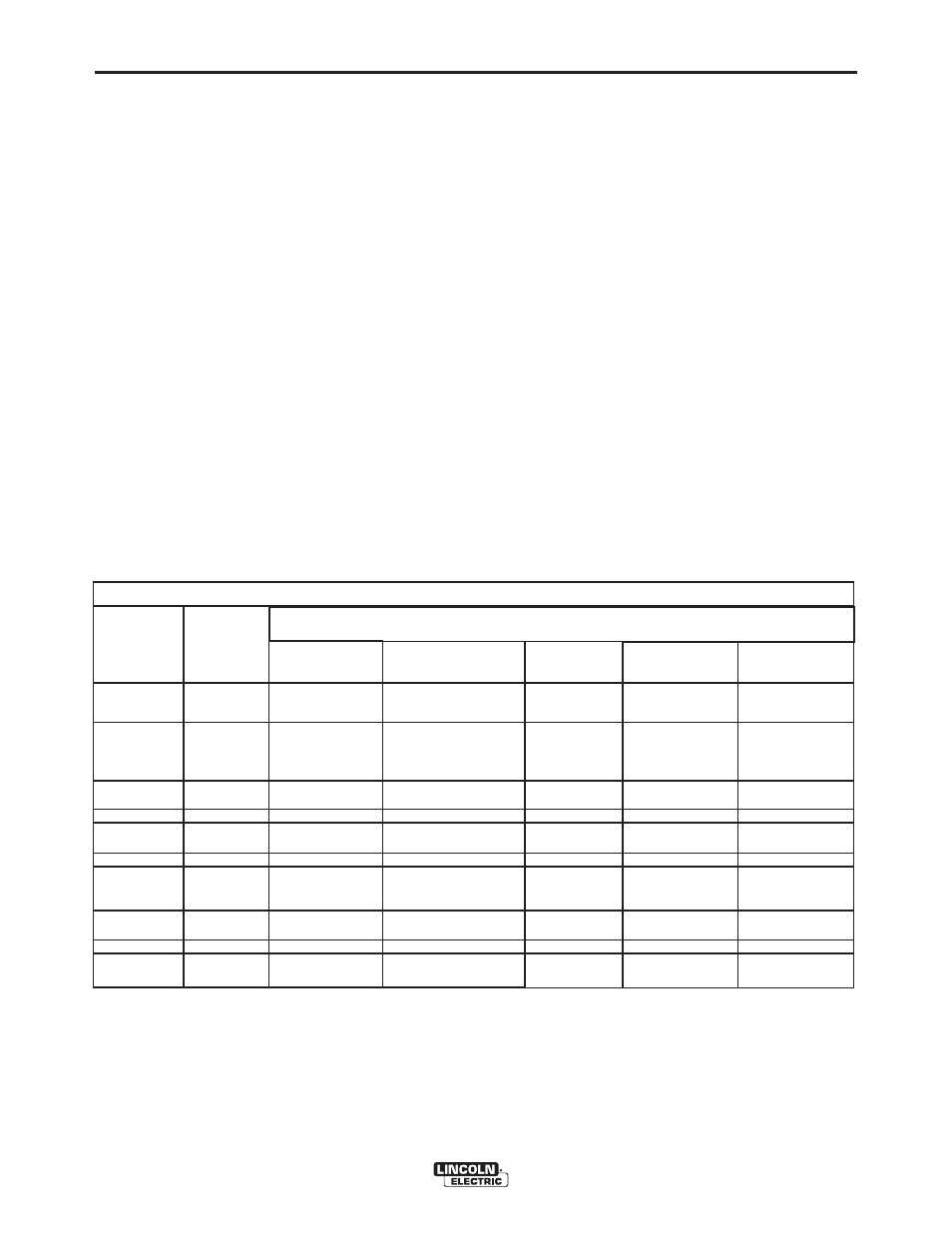

RECOMMENDED ELECTRODE AND

WORK CABLE SIZES FOR ARC WELDING

General Guidelines

Connect the electrode and work cables between the

appropriate output studs of the FLEXTEC™ 650 per

the following guidelines:

• Most welding applications run with the electrode

being positive (+). For those applications, connect

the electrode cable between the wire drive feed

plate and the positive (+) output stud on the power

source. Connect a work lead from the negative (-)

power source output stud to the work piece.

• When negative electrode polarity is required, such

as in some Innershield applications, reverse the out-

put connections at the power source (electrode

cable to the negative (-) stud, and work cable to the

positive (+) stud).

The following recommendations apply to all output

polarities and weld modes:

• Select the appropriate size cables per the

“Output Cable Guidelines” (See Table A.1).

Excessive voltage drops caused by undersized

welding cables and poor connections often result in

unsatisfactory welding performance. Always use the

largest welding cables (electrode and work) that are

practical, and be sure all connections are clean and

tight.

Note: Excessive heat in the weld circuit indicates

undersized cables and/or bad connections.

• Route all cables directly to the work and wire

feeder, avoid excessive lengths and do not coil

excess cable. Route the electrode and work cables

in close proximity to one another to minimize the

loop area and therefore the inductance of the weld

circuit.

• Always weld in a direction away from the work

(ground) connection.

** Tabled values are for operation at ambient temperatures of 104°F(40°C) and below. Applications above 104°F(40°C) may require cables

larger than recommended, or cables rated higher than 167°F(75°C).

OUTPUT CABLE GUIDELINES

CABLE SIZES FOR COMBINED LENGTHS OF ELECTRODE AND WORK CABLES

(RUBBER COVERED COPPER - RATED 167°F or 75°C)**

AMPERES

200

200

250

250

250

250

300

300

350

400

400

500

600

600

600

650

650

700

800

800

PERCENT

DUTY

CYCLE

60

100

30

40

60

100

60

100

40

60

100

60

60

80

100

60

80

100

80

100

0 to 50Ft.

(0 to15m)

2

2

3

2

1

1

1

2/0

1/0

2/0

3/0

2/0

3/0

2-1/0

2-1/0

3/0

2-1/0

2-2/0

3-1/0

2-3/0

50 to 100Ft.

(15 to 30m)

2

2

3

2

1

1

1

2/0

1/0

2/0

3/0

2/0

3/0

2-1/0

2-1/0

3/0

2-1/0

2-2/0

3-1/0

2-3/0

100 to 150 Ft.

(30 to 46m)

2

2

2

1

1

1

1

2/0

2/0

2/0

3/0

3/0

3/0

2-1/0

2-1/0

4/0

2-1/0

2-3/0

3-1/0

2-3/0

150 to 200 Ft.

(46 to 61m)

1

1

1

1

1

1

1/0

2/0

2/0

3/0

3/0

3/0

4/0

2-2/0

2-2/0

2-2/0

2-2/0

2-3/0

2-3/0

2-3/0

200 to 250 Ft.

(61 to 76m)

1/0

1/0

1/0

1/0

1/0

1/0

2/0

3/0

3/0

4/0

4/0

4/0

2-3/0

2-3/0

2-3/0

2-3/0

2-3/0

2-4/0

2-4/0

2-4/0

TABLE A.1