Maintenance, Warning – Lincoln Electric IM10059 SQUARE WAVE TIG 175 User Manual

Page 18

D-1

MAINTENANCE

D-1

SQUARE WAVE™ TIG 175

ELECTRIC SHOCK can kill.

• Only qualified personnel should

perform this maintenance.

• Turn the input power OFF at the

disconnect switch or fuse box

before working on this

equipment.

• Do not touch electrically hot

parts.

To avoid receiving a high frequency shock, keep the

TIG torch and cables in good condition.

1.

Disconnect power supply lines to machine before

performing periodic maintenance.

2.

Periodically clean the inside of the machine with a

low pressure air system. Be sure to clean the

following components thoroughly.

• Main Transformer

• Electrode/Gas Output Receptacle

• Polarity Switch

• Rectifier Assembly

• Arc Starter/Spark Gap Assembly

• PC Boards

• Fan Blades

3.

Inspect welder output and control cables for

fraying, cuts, and bare spots.

4.

Keep TIG torch and cables in good condition.

5.

Clean air louvers or brickwork to ensure proper air

flow and cooling.

6.

The fan motor has sealed ball bearings which

require no maintenance.

7.

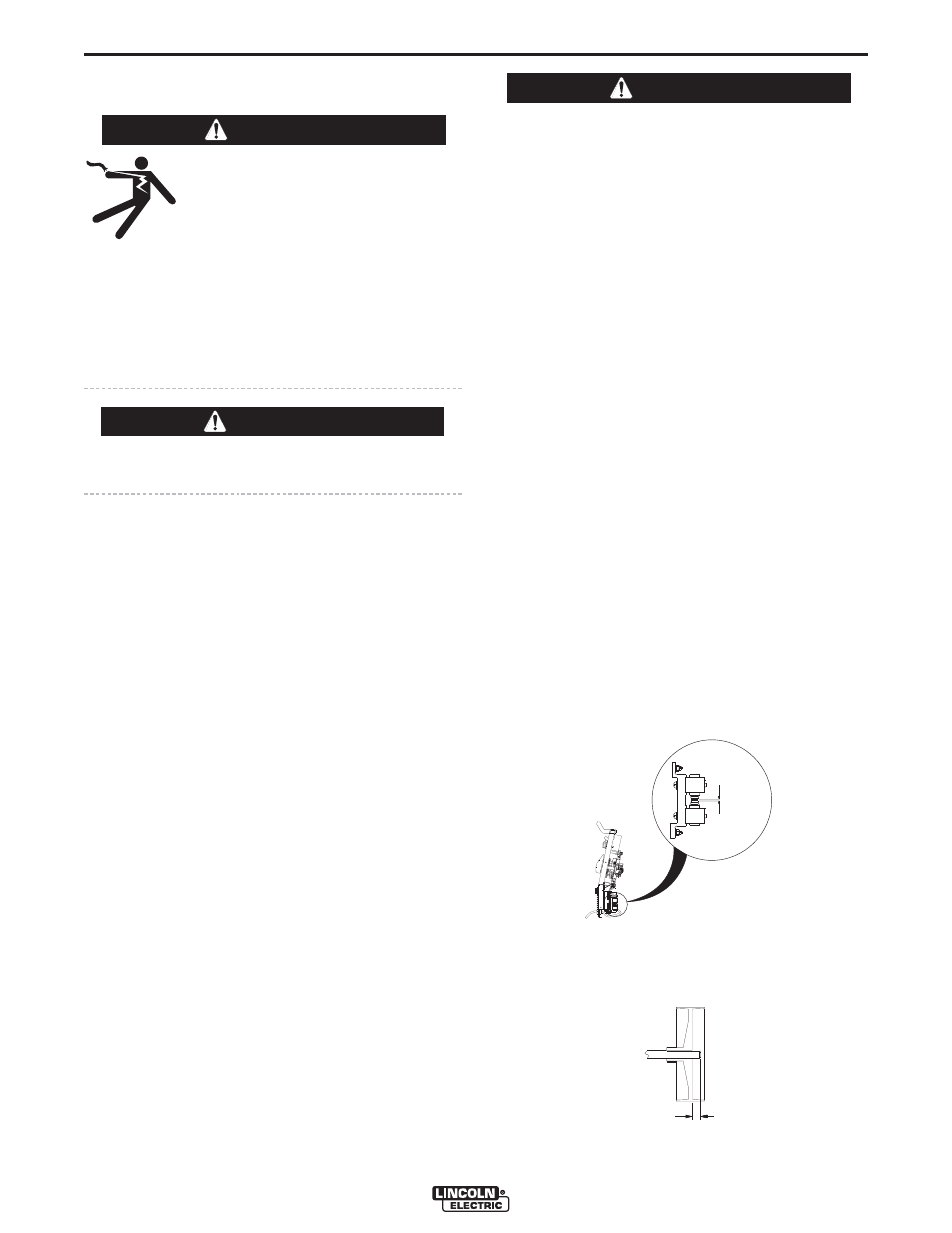

SPARK GAP ADJUSTMENT

The spark gap is set at the factory to a gap of

0.015 inches (0.4mm) See Figure C.1. This setting

is adequate for most applications. Where less high

frequency is desired, the setting can be reduced to

0.008 inches (0.2mm).

SAFETY PRECAUTIONS

ROUTINE AND PERIODIC MAINTENANCE

WARNING

WARNING

Use extreme caution when working with circuit of the high

frequency. The high voltages developed can be lethal. Turn

the input power off using the disconnect switch or fuse box

before working inside machine. This is particularly impor-

tant when working on the secondary circuit of the high volt-

age transformer (T3) because the output voltage is danger-

ously high.

Refer to figure C.1. Note in highly dirty environments where

there is an abundance of conductive contaminants, use a low

pressure air stream or a firm piece of paper to clean the spark

gap. Do not disturb the factory setting.

To check the spark gap:

- Turn off input power as specified above.

- Remove the (wraparound Code 11691) or (right case side

Code 11826) from the machine, the spark gap is located

on the lower right side.

- Check the spark gap with a feeler gauge.

If adjustment is needed:

- Adjust the gap by loosening the allen head screw in one of

the aluminum blocks, and tighten the screw in the new

position.

If the gap is correct:

- Replace the (wraparound Code 11691) or (right case side

Code 11826).

8.

Inspect gas hose and inlet fitting for cracks or leaks.

9.

Replace any unreadable labels or decals.

10. Verify that the machine and welding circuit is properly

grounded.

.015 Spark Gap

RIGHT SIDE OF MACHINE

FIGURE C.1 SPARK GAP

FAN MOTOR OR FAN BLADE REPLACEMENT

When installing a new fan blade or fan motor be sure

to maintain proper shaft spacing per Figure C.2 below.

.30

Figure C.2

WARNING