Service & maintenance – Yuh Dak SIC-A series User Manual

Page 23

7. Service & Maintenance

7. Service & Maintenance

7-1

All repair work should be done by qualified personnel only to avoid damage

the machine or personnel injury.

to

In order to operate the machine rightly and safely, please caution the matter

follows:

1) Do not turn off the main power switch to stop the machine,except emergency

situation.

2) When failures set in and the machine stop work with buzzer sound, first press

the main power switch of the machine (alarm indicator will die)

then go

the reason of the failures, do not force the machine on before remove

3) please check periodicaly to prolong the life of the machine and prevent the

accident to appear.

4) water supply should be processed, because the high PH can corrode the copper

pipe acute. This must reduce the life of the heating and cooling implement, PH

water supply must be between 7.0

8.5.

5) keep the machine room dry,clean and vent.

6) the operation and service of the machine should be done by qualified technician

only.

(

!)

as

down

to check

the failures.

safety

of the

Please take notice that the disassembly and the inspection of the machines are

hazardous when the machines are running

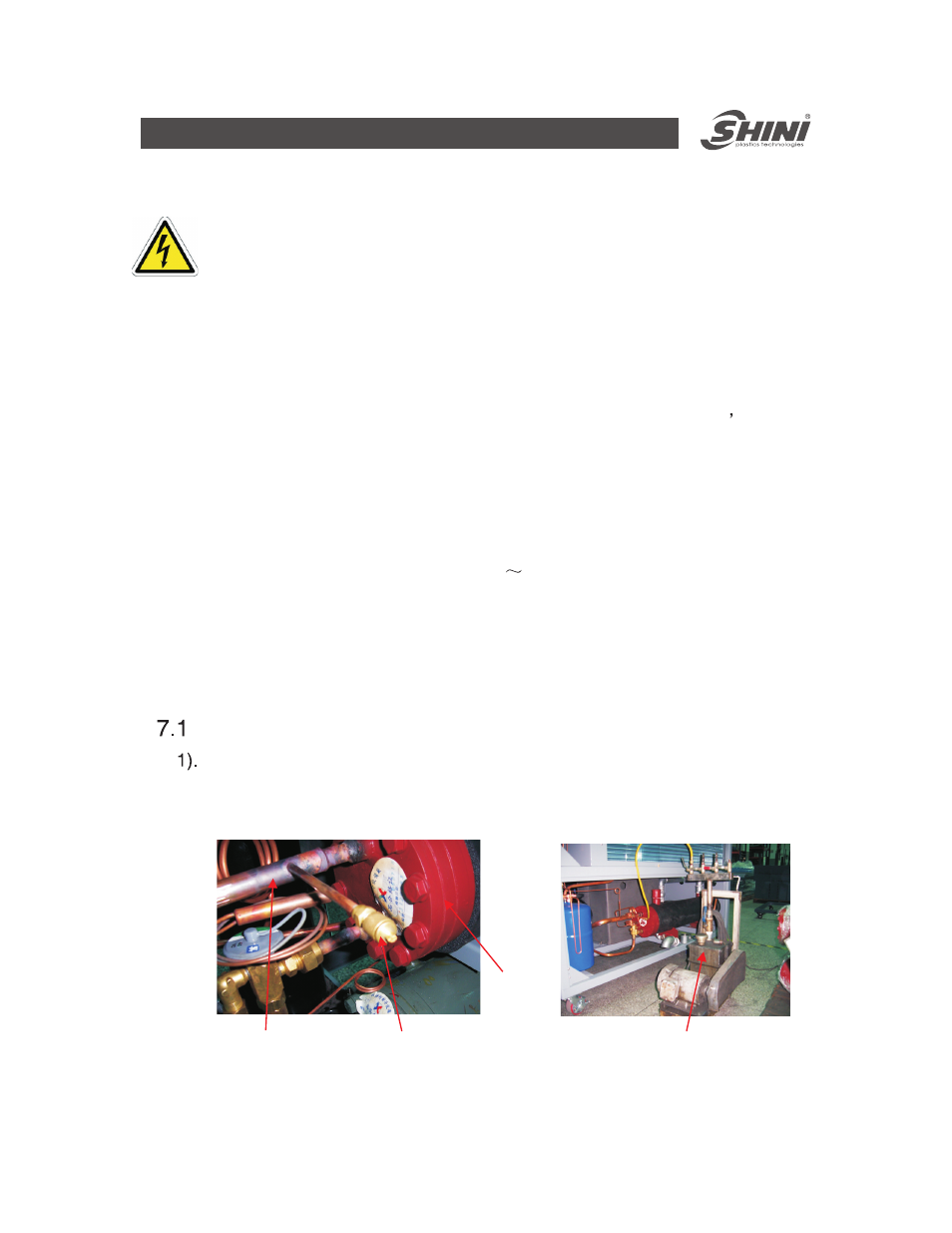

Screw off the end cap of the liquid filling thimble valve, and connect the air

suction pipe of the vacuum pump to the liquid filling thimble valve to take the

vacuum pumping, and this process may take one to two hours.

Fill in the refrigerant

The end cap of the

liquid filling thimble valve

The

evaporation

The air return pipe

The vacuum pump