Warning, Installation final check, Installing the wire rope – WARN 30XL Series User Manual

Page 9

9

WARN Industrial Winches

Installation Final

Check

• Recheck mounting hardware for loose bolts,

etc.

• Be sure all hydraulic system components

and connections are correct

• Be sure all connections are tight and secure

• Check motor rotation: The drum should

rotate counterclockwise when viewed from

the motor end when hydraulic fluid is

supplied to Port A of the motor.

• To ensure maximum hydraulic motor life,

the winch should be operated for one hour

at no more than 30% of rated load before

application of full load.

The wire rope may be spooled on the winch drum

in either direction. Always follow the guidelines

for pull direction listed under Mounting the Winch.

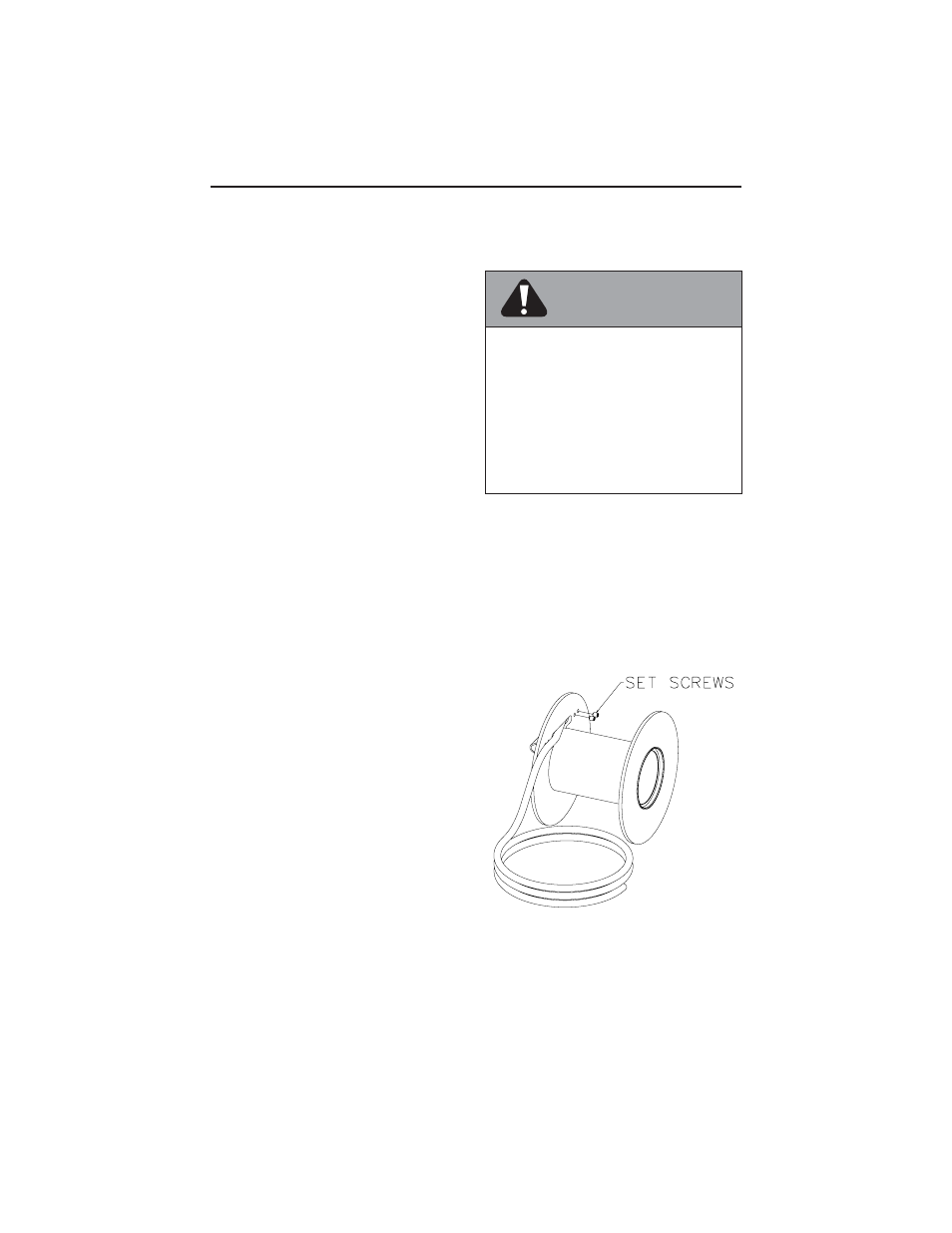

1 Insert the end of the wire rope into the anchor

hole in the drum flange. NOTE: A small

piece of tape around the end of the wire rope

will make installation much easier. The wire

rope must extend to the other end of the hole.

2 Torque the set screws to 12-15 lb-ft (16-20 N-

m). Do not overtighten as this may cause the

screw threads to be damaged. Ensure both

(2) set screws secure the wire rope. Ensure

both (2) set screws do not protrude from the

drum flange.

3 With end of rope securely installed, carefully

wind the rope evenly onto the drum. Keep

the rope under tension at all times.

4 Always maintain a minimum of five (5) wraps

of rope on the drum. Fewer wraps may cause

the end of the rope to pull free of the drum

and drop the load.

Installing the Wire

Rope

Anchoring Wire Rope on Drum

WARNING

Failure to observe these instructions could

lead to property damage, severe injury, or

death.

• Always maintain a minimum of five (5)

wraps ofrope on the drum.

• Always use wire rope specified on the

product data sheet.

• Always install rope according to the

illustration below.