Periodic preventive maintenance, Preventive maintenance schedule – WARN 30XL Series User Manual

Page 12

12

WARN Industrial Winches

• Keep winch free of dirt, oil, grease, water

and other substances. Remove any

overflow grease from bearings.

• Check all mounting bolts and make sure

they are tightened to proper torque.

Replace any damaged fasteners.

• Periodically check all hydraulic connections

to be sure they are tight and free of

corrosion.

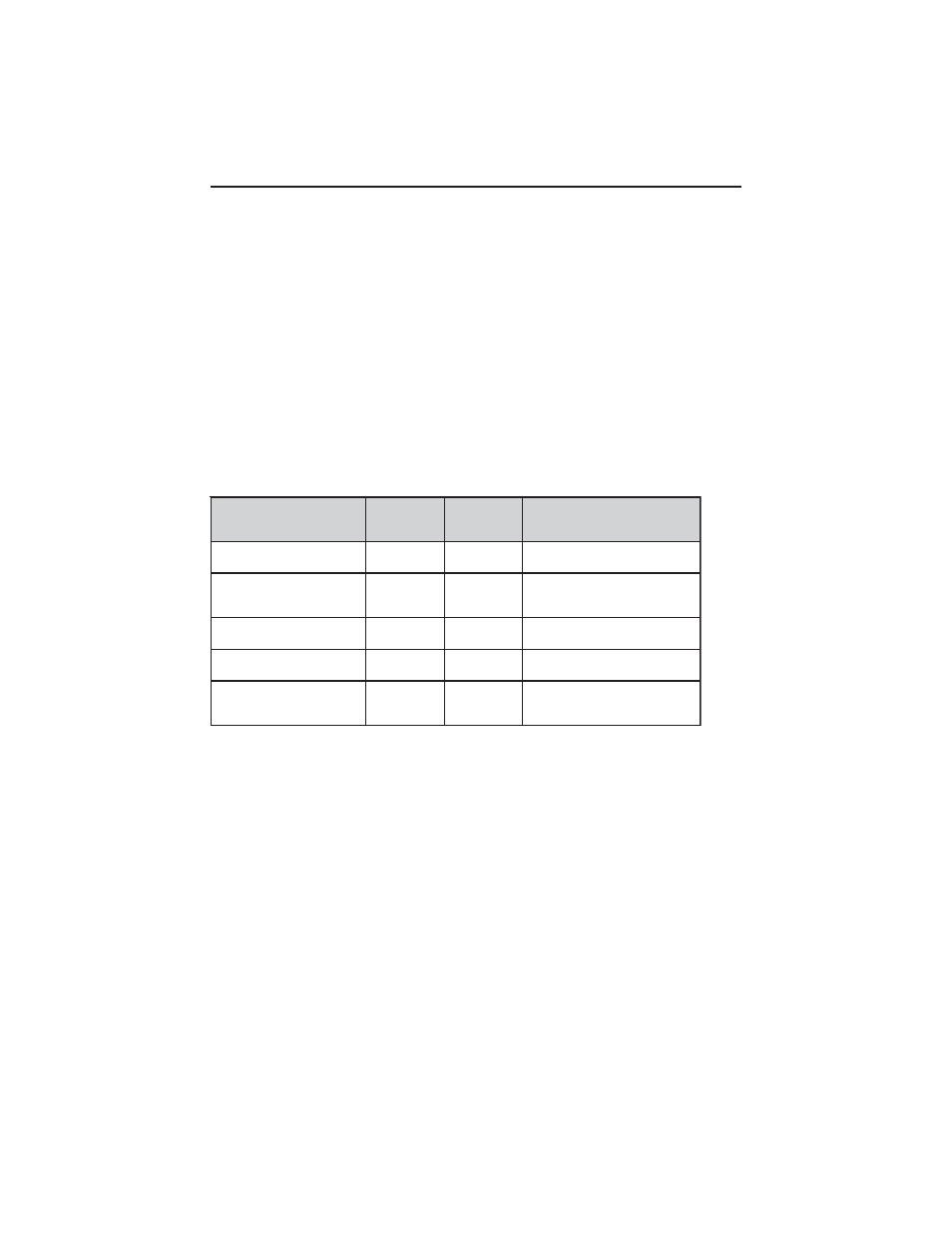

Preventive maintenance schedule

Periodic Preventive Maintenance

• Check rope for visible damage every time

winch is operated. Examples of damage

are: cuts, knots, mashed or frayed portions,

and broken strands. Replace rope

immediately if damaged. Failure to replace

a damaged rope could result in breakage.

• If winch drum continues to turn after

controls are released, brake may need to

be replaced.

NOTE: Hydraulic system failures typically follow the same pattern: a gradual or sudden loss of

pressure or flow resulting in a loss of motor power. Any one of the system components may be at fault.

Refer to the table for general recommendations. If necessary, consult a knowledgeable hydraulics

representative.

NOTE: See product data sheet for hydraulic specifications.

y

t

i

v

i

t

c

a

e

c

n

a

n

e

t

n

i

a

M

t

s

r

i

f

r

e

t

f

A

n

o

i

t

a

r

e

p

o

e

r

o

f

e

B

e

s

u

h

c

a

e

h

c

a

e

r

e

t

f

a

r

o

y

l

l

a

u

n

n

a

-

i

m

e

S

n

o

i

t

a

r

e

p

o

f

o

s

r

u

o

h

5

2

s

r

e

n

e

t

s

a

f

k

c

e

h

C

X

X

c

il

u

a

r

d

y

h

k

c

e

h

C

s

n

o

i

t

c

e

n

n

o

c

X

X

e

p

o

r

k

c

e

h

c

d

n

a

t

u

o

l

o

o

p

S

X

s

e

h

s

u

r

b

r

o

t

o

m

k

c

e

h

C

X

h

c

n

i

w

f

o

k

c

e

h

c

l

a

u

s

i

V

e

v

l

a

v

l

o

r

t

n

o

c

d

n

a

X

X

X