Superwinch TALON SERIES WINCH Installation User Manual

Page 4

4

Improper mounting

can cause personal

injury. Improper mounting could

damage your winch and void the war-

ranty.

MINIMUM ELECTRICAL REQUIREMENTS

A 60 amp. alternator and battery with

440 cold-cranking amperes capacity

are the minimum recommended power

sources. If the winch is in heavy use, an

auxiliary battery is recommended.

Under some circumstances, it may be

appropriate to install additional circuit

protection devices (circuit breakers). If in

doubt, seek appropriate advice.

Superwinch recommends that all winch

electrical systems can be readily and

quickly isolated from their electrical sup-

ply in the event of an emergency. The

winch electrical’s system should always

be isolated when the winch is not in use.

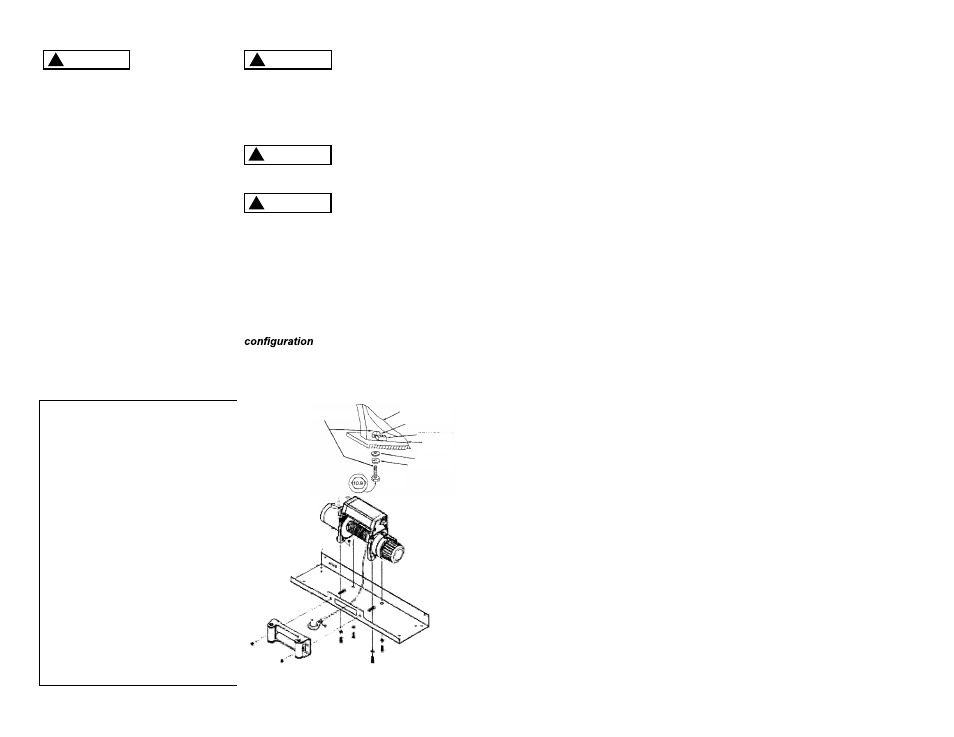

1. Install mounting kit or structural sup-

port for the winch.

2. Mount the winch to a mounting plate

or to a mount that you have properly

designed.

Your winch is a very

powerful machine.

To protect yourself and property, the

winch must be properly mounted to a

structural support capable of with-

standing the high pulling capacity of

the winch.

Do not substitute

any strength grade

weaker than SAE Grade 8 (ISO 10.9).

When mounting

your winch in a foot

- forward position, the solenoid pack

can be rotated to be on top of the

motor or can be remote-mounted. To

rotate the solenoid box, remove the

two motor screws and solenoid box

bracket screws. Rotate the motor and

solenoid box upwards and reinstall

the screws. If remote mounting, the

solenoid pack may be mounted in any

EXCEPT inverted

(i.e. solenoid studs facing down).

Inverted mounting may cause erratic

operation. Use properly sized wire or

contact Superwinch for remote mount

kit options.

!

WARNING

!

!

WARNING

!

!

WARNING

!

CAUTION

!

INSTALLATION

Figure 2

25

(NOTES,

NOTAS)

If not using a Superwinch mounting

accessory, follow the general

guidelines listed below.

For 9.5 and 12.5 models:

(see Fig 2 insert)

Mounting plate must be minimum 1/4”

(6.3mm) thick. Mounting bolt threads must

fully engage nut, but bolt must not contact

opposite side of nut pocket in casting. All 4

mounting bolts must be used to secure the

winch.

For 14.0 and 18.0 models:

Mounting hardware suppied with winch is

sized for a 5/16” (8mm) thick mounting plate.

For thicker mounting plates, minimum 18mm

(0.700”) bolt engagement in casting is

required. Bolts must not bottom out in the

tapped holes before being fully tightened. All

8 mounting bolts should be used when

possible. Minimum of 4 bolts required.

6.5” x 10” (165.1mm x 254mm) pattered is prefered

4.5“ x 10” (114.3mm x 254mm) pattern is acceptable.

M

(Must not touch)

Support Casting

Mounting Pocket

Nut

Mounting Plate

Flat Washer

Lock Washer

Bolt