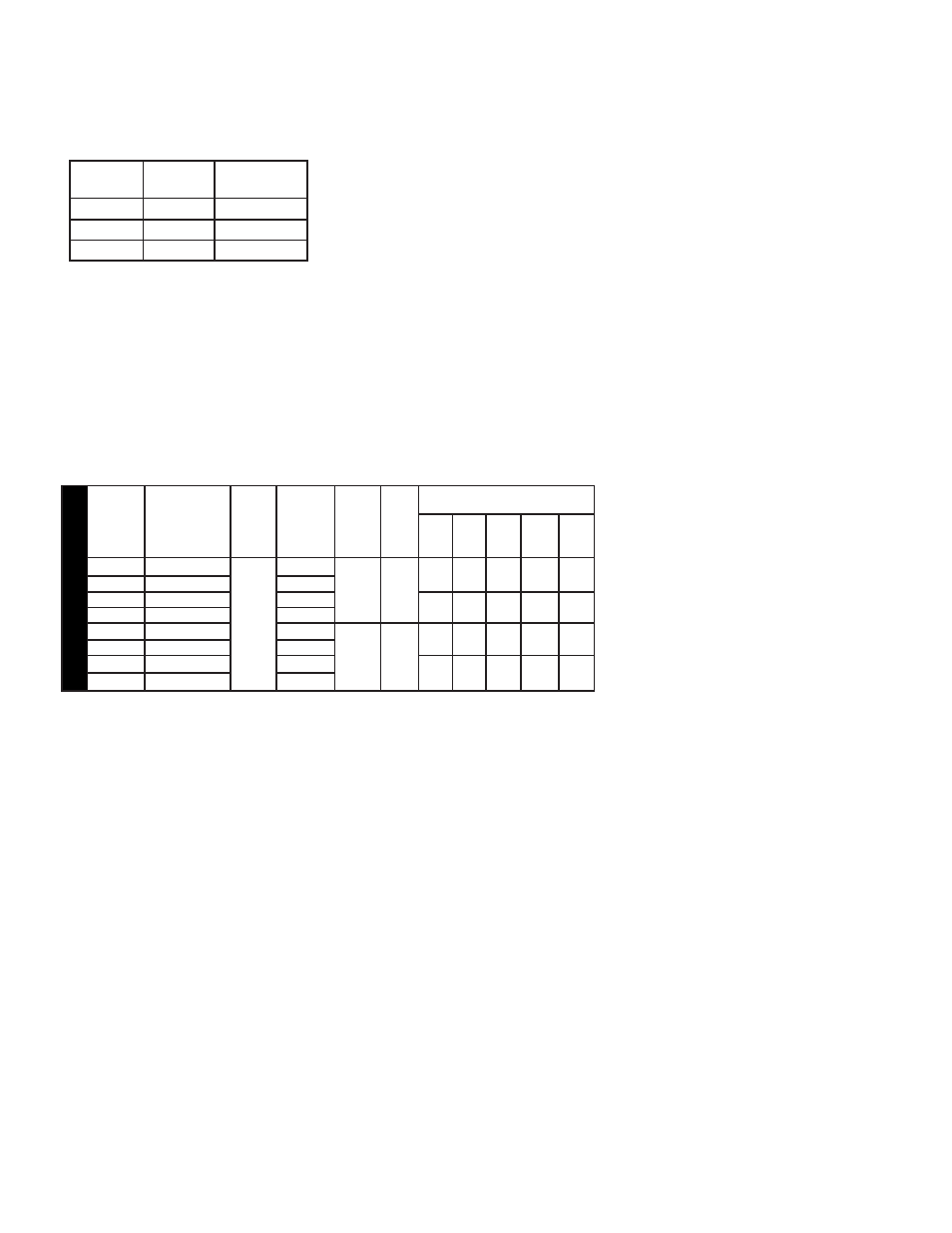

4p art numbers – LEESON 210 C-Face Motors User Manual

Page 4

4

P

ART NUMBERS

Leeson

Part Num-

ber

Stearns Part

Number

Brake

Coil

Rating

(VAC)

NEMA

Enclosure

Brake

Bore &

Shaft

Dia.

(U/X)

NEMA

Frame

Size

Dimensions (Inches)

A

C

A

E

A

G

A

H

175583.00 1087721011QG

230/460

2

1-1/8”

180

8.38

2.81

2.12

0.19

2.62

175584.00 1087722B11QG

4X

175585.00 1087731011QG

2

8.38

2.81

2.12

0.19

2.62

175586.00 1087732B11QG

4X

175587.00 1087741031QG

2

1-3/8”

210

8.38

2.81

2.12

0.19

3.12

175588.00 1087742B31QG

4X

175589.00 1087751031QG

2

8.88

3.31

2.62

0.44

3.12

175590.00 1087752B31QG

4X

18. If a heater is supplied and excess rusting

has occurred in brake, check power source

to heater to be sure it is operating and that

heater is not burned out.

19. If stopping time is more than two seconds

(rule of thumb) and/or the application is

more than five stops per minute, check

thermal requirements of load versus ther-

mal rating of brake.

20. Use Loctite

®

242 to secure link screw nut

to link screw if vibration causes nut to

loosen.

B. If brake hums, solenoid pulls in slow-

ly, or coil burns out, check the following:

1. Voltage supply at coil versus coil rating.

2. Is solenoid air gap excessive?

(See

Self-Adjust Maintenance

.)

3. Shading coils may be broken.

4. Plunger guides may be excessively worn.

Does solenoid plunger rub on solenoid

frame laminations? If so, replace plunger

guides.

5. Solenoid frame and plunger may be exces-

sively worn.

6. Is solenoid dirty?

7. Solenoid mounting screws may have

become loose, causing frame to shift and

plunger to seat improperly.

8. Sector gear and pinion teeth may be jam-

ming due to excessive tooth wear.

9. Excessive voltage drop when motor starts.

Check size of lead wires for motor starting

current and solenoid inrush current. See

Section IV-A, Item 11, 12, 14 and 15.

C. If brake is noisy during stopping:

1. Check mounting face run out, mounting rab-

bet eccentricity and shaft run out. See

Installation Procedure

, Section I, Note 1.

Correct as required.

2. Check for signs of the outside diameter of

the friction disc(s) rubbing on the inside

diameter of the endplate. This would indicate

brake is eccentric with respect to the motor

shaft and/or the shaft is deflecting during a

stop. Check alignment and shaft diameter.

Also check for worn motor bearings. If

realignment does not correct the problem, a

larger diameter shaft may be required. Shaft

deflection may also be caused by excessive

overhang of brake from motor bearing.

Additional shaft support may be required.

3. Check for bad motor bearings. Replace

if necessary. Check for excessive shaft end-

float. Correct as required.

Color

Torque

(lb-ft)

Compressed

Spring Length

White

15

3-1/4”

Orange

25 & 50

3-1/4”

Purple

35

3-1/4”