LEESON 210 C-Face Motors User Manual

Page 3

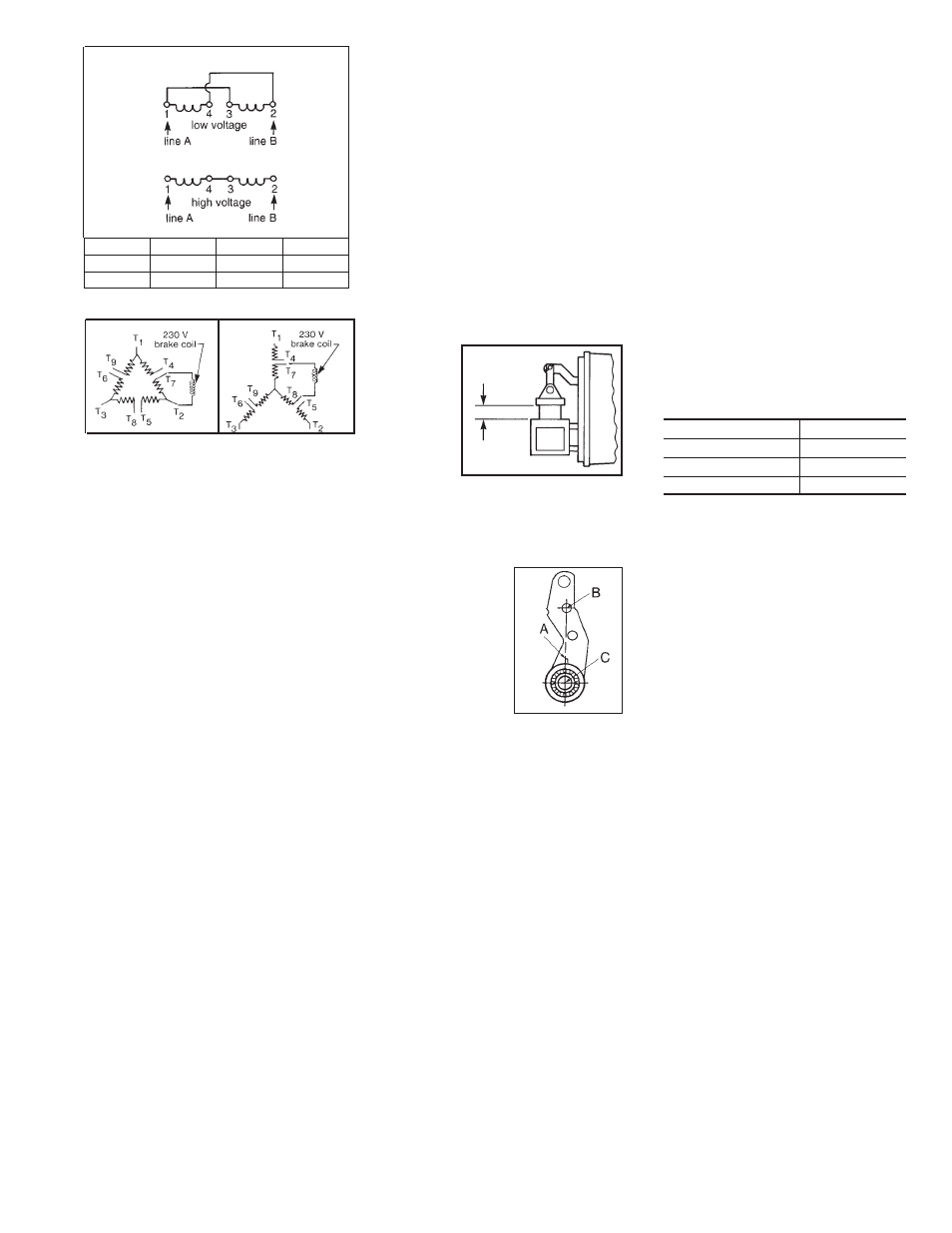

connected as shown in figures 4 and 5 the

motor can be operated on either 230 volts or

460 volts with no effect on brake operation.

III. General Maintenance

Warning!

Any mechanism or load held in posi-

tion by the brake should be secured to prevent

possible injury to personnel or damage to

equipment before any disassembly of the

brake is attempted or the manual release lever

is operated on the brake. Observe all

cautions

listed at the beginning of this manual.

Note 1:

Replacement part kits for many items

are available and contain retrofit instructions.

Note 2:

Do not lubricate any part of the brake

as this may cause a malfunction and/or loss of

torque.

A. Coil replacement

All standard NEMA AC voltage coils are avail-

able in kits. Select coil kit from appropriate

replacement parts list for the particular brake

series being serviced.

B. Friction disc replacement

Note: Replace friction discs in single disc

brakes when wear surface area is one half the

original disc thickness (1/4

″). In multiple disc

brakes, replace all friction discs when throat of

lever arm is within 1/16

″ of touching teeth of

pinion.

C. Self-adjust maintenance

Since the self-adjust brake automatically

adjusts itself for friction disc wear, maintenance

is held to a minimum. The solenoid is factory

set with a 13/16

″ to 15/16″ air gap, and

requires no resetting, even when changing fric-

tion discs. The gap is determined by the posi-

tion of wrap spring stop (76). Should air gap

change, follow the steps listed below:

1. If (stop) screws (76S) had been loosened

and retightened, the air gap may require

resetting. The gap is measured between

mating surfaces of plunger (29) and solenoid

frame (79), and may be increased by raising

slightly, or decreased by lowering slightly,

wrap spring stop (76). Be sure to retighten

(stop) screws (76S). Manually lift plunger to

maximum travel and release. Depress

plunger, manually or electrically, and allow it

to snap up. Repeat several times, then

recheck air gap for factory setting of 13/16

″

to 15/16

″.

Note:

To measure solenoid air gap on verti-

cally mounted brakes, grasp solenoid link to

hold plunger in a free horizontal position and

move toward solenoid frame until spring

pressure is felt. Holding firmly in this position

measure air gap between mating (ground)

surface on solenoid frame and solenoid

plunger. Adjust to proper gap as directed in

Self-Adjust Maintenance. Check gap by

again holding plunger as directed.

2. Tang of wrap spring must be below, and

must make contact with, wrap spring stop

(76) when

solenoid lever

(28) is manual-

ly raised. If

stop is bent

outward, allow-

ing tang to

bypass it,

rebend to

square posi-

tion, assemble

correctly, and reset solenoid air gap as

described in Paragraph 1.

3. Should air gap have decreased or disap-

peared, the solenoid lever and pinion

assembly (8) may have

become contaminated

due to lubrication or

residue as a result of

overheating of brake.

For reference purposes

refer to Figure 7. Tang A

should align with the

centerline of hole B.

Use kit #5-66-7371-00 if

replacement is neces-

sary.

4. Check condition and positioning of

pinion and rack assembly. Replace parts as

necessary with complete assemblies.

D. Solenoid lever and pinion assembly

replacement

If pinion teeth are worn, replace entire assem-

bly. Consult appropriate parts list for kit num-

ber. Check sector gear of lever arm for wear.

If sector gear teeth of lever arm are worn,

replace entire lever arm assembly available as

a kit from appropriate repair parts list. Also

check pinion teeth for wear.

E. Drain plug removal (WASHGUARD

brakes only)

If moisture has accumulated inside the brake

enclosure, remove the drain plug (location

shown in Figure 1). Replace plug after fluid has

drained.

IV. Troubleshooting

A. If brake does not stop properly or

overheats, check the following:

1. Is manual release engaged, and is motor

energized?

2. Friction discs may be excessively worn,

charred or broken.

3. Hub may have become loose and shifted

on shaft.

4. Is hub clean and do friction discs slide

freely?

5. Are controls which govern start of brake

cycles operating properly?

6. Are limit switches, electric eyes, etc. func-

tioning properly?

7. On vertically mounted brakes, are

springs in place in disc pack?

See P/N 8-078-937-06.

8. Have mounting faces loosened?

9. Pressure spring may be improperly assem-

bled or broken.

10. Is solenoid air gap adjusted correctly?

(See

Self-Adjust Maintenance

,

Section III, Item D.)

11. Check linkage for binding. The approximate

pressure applied to the top of the solenoid

link to move plunger is:

If excessive force is required, determine

cause of binding and correct. Do not over-

look bent, worn or broken plunger guides

as a possible cause for binding.

12. Solenoid lever stop (22) must be in place

on support plate.

13. Solenoid may not be energizing and releas-

ing the brake. Check voltage at the coil and

compare to the coil and/or nameplate volt-

age rating.

14. A voltage drop may be occurring. If exces-

sive drop in voltage is noted, check wire

size of power source. Correct as needed.

Note:

A method to check voltage at coil is

to insert a block of wood of the approxi-

mate thickness of the solenoid air gap

between the solenoid frame and plunger.

(The block will prevent brake from releas-

ing when coil is energized.) Connect volt-

meter leads at the coil terminals or lead

wires. Energize coil. Voltmeter needle will

not fluctuate and reading can be taken.

Reading should be taken immediately and

the coil de-energized to prevent over-heat-

ing of the coil. Compare voltage reading

with coil rating.

15. Check slots of endplate for wear at the

areas where stationary discs are in contact.

Grooves in the slots can cause hang-up or

even breakage of ears of stationary discs.

If grooving is noted, replace endplate.

16. Check that heads of mounting bolts do not

extend above wear surface of endplate.

17. Check pressure spring length to insure cor-

rect compressed height. Approximate origi-

nal spring lengths are given in the following

table so that correct setting may be verified

and corrected if necessary. With worn fric-

tion discs, add amount of wear to the

approximate spring length shown in table.

Figure 6

Figure 7

16 lbs

#8 coil

9 lbs

#6 coil (25 lb-ft)

5-1/2 lbs

#6 coil (15 lb-ft)

3 lbs

#5 coil

3

AC Voltage Coil Connection

Figure 3

3 and 4

2

1

High voltage

–

2 and 4

1 and 3

Low voltage

Tie Leads

Power Line B

Power Line A

For

Figure 4

Figure 5

Class B Coil (black)

Air

gap