LEESON 210 C-Face Motors User Manual

Page 2

General Description

The 87,700 Series coupler is a spring-set, elec-

trically released, self adjusting brake. The dou-

ble C-face allows the brake to directly couple a

C-face motor to a C-face gear reducer. Or, for

in-line application, the brake can be mounted

directly to a foot mounted

C-face motor, using the bearing mounted output

shaft as an in-line drive shaft.

Note: Coupler brake is designed for in-line

applications only. Do not apply overhung or side

load to brake output shaft.

I. Installation Procedure

Note 1:

Check face of motor to which brake is

to be mounted, to be sure NEMA dimensions of

0.004

″ T.I.R. on concentricity and face run out

are met. Shaft run out is to be within 0.002

″

T.I.R. Maximum shaft end float is 0.020

″. Use

standard length NEMA shaft.

Note 2:

The effectiveness of the dust-tight

waterproof brake enclosure depends on a fully

enclosed motor C-face as the brake face is not

sealed.

A. Remove hub (16) from brake assembly. With

key (not furnished) in place on motor shaft,

slide hub onto shaft to 1” (

± 1/32”) of stan-

dard motor C-face. Tighten the three set

screws over the motor shaft to 290 in-lb (on

single disc brake, the set screw over the

keyway should be tightened to 87 in-lb).

Note 3:

On most applications, particularly in

vertical position, a set screw dimple drilled

into shaft is recommended.

B. Remove housing bolts (15), lock washers

(15W) and housing (7).

C. Depress solenoid plunger (29) and tie

plunger to frame (79).

D. Remove entire support plate assembly (142)

by evenly unscrewing screws (142S).

Remove screws, conical spring washers

(142W), and flat washers (142X).

E. Remove pressure plate (5), friction disc (4)

and stationary disc (3).

F. Attach endplate (2) to NEMA C-face of

motor using four 1/2-13 socket head cap

screws and medium spring lock washers

(not supplied) torque per manufacturer’s

specifications. (Head of cap screws must

not project above friction surface.)

Note 4:

If motor, with or without reducer, is

to be ceiling mounted after assembly, entire

brake will have to be rotated 180

° or upside

down so it will be positioned with solenoid

plunger (29) above frame when final assem-

bly is mounted on ceiling. Similarly, for hori-

zontal wall mounting, rotate 90

°.

G. Reassemble friction discs (be sure

friction discs slide freely, file I.D. if neces-

sary), springs (if vertical), stationary discs,

and pressure plate in correct sequence and

position. All parts must

slide freely. The universal mounting pressure

plate presently used has three tapered reliefs

on outboard face.

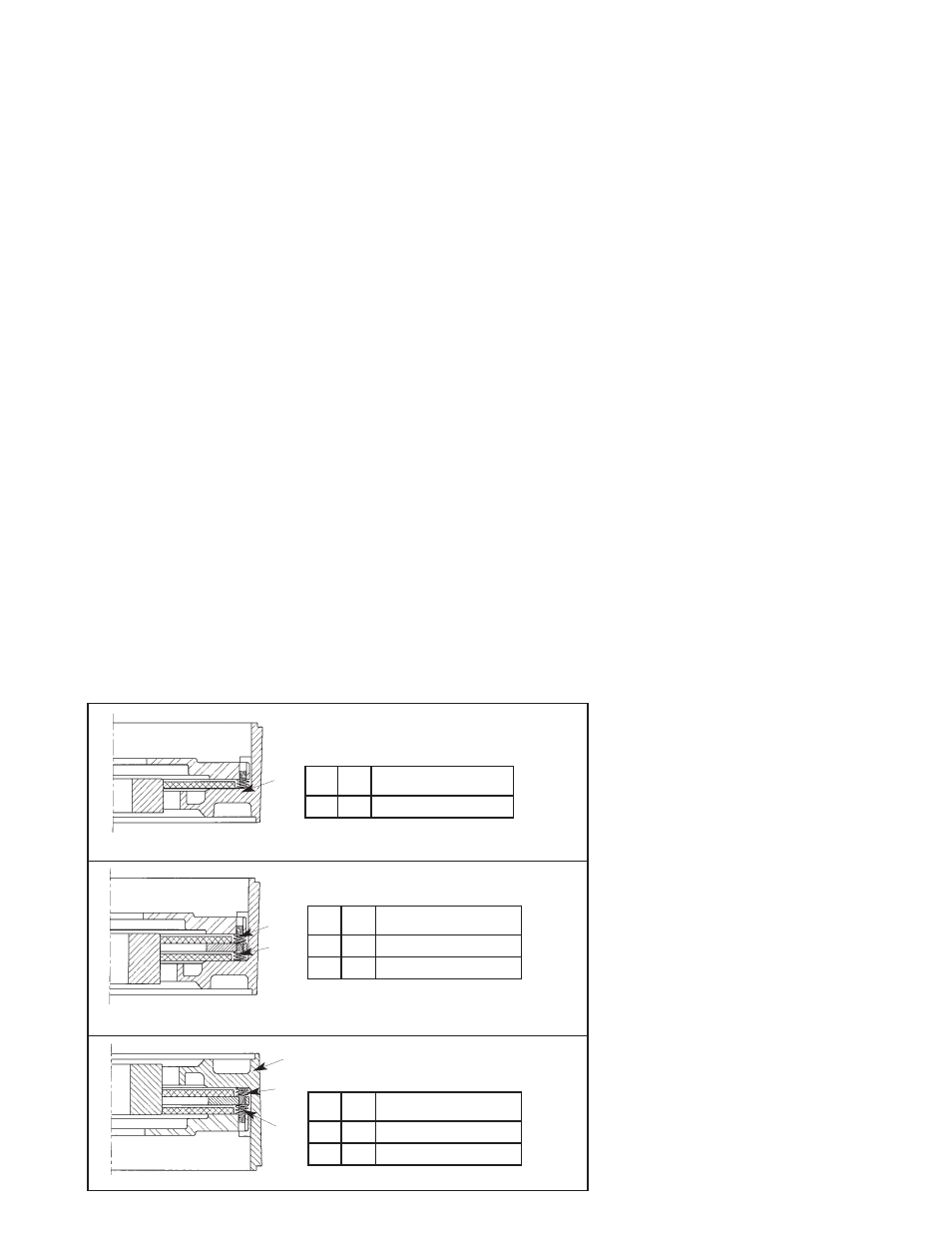

Note 5:

Brakes with a single friction disc do

not have stationary discs. Vertically mounted

brakes will have springs to separate station-

ary discs (except one disc vertical below).

Note color coded sequence of springs (fig-

ures 2A, 2B, & 2C) for proper assembly of

vertical mounting components.

H. Mount support plate assembly, torque

screws to 50 in-lbs in endplate. Conical

spring washer installed under the screw

head. Flat washer used under the

conical spring washer only with

aluminum support plate. Be sure that assem-

bly is mounted with the solenoid

in a vertical position (plunger above frame)

as shown when brake is horizontal. If

plunger is not tied down and has allowed the

mechanism to overadjust, it will have

to be reset before mounting support plate.

In this case the lever arm throat will

be near, or touching, the pinion teeth. Refer

to

Self-Adjust Maintenance

. Loosen pres-

sure spring cap screw (19) until pressure

spring (11) is free, mount support plate

assembly to endplate, and retighten spring

cap screw until snug. Do not overtighten!

Torque to a maximum of

100 in-lbs.

I. Remove plunger tie-down. Manually

lift solenoid plunger to maximum travel

and release. Complete electrical connec-

tions, (See Section on

Electrical

Connection of Brake

.) Depress solenoid

plunger manually or electrically, and allow

it to snap up.

Repeat this process several times to set air

gap on solenoid. (Check

Self-Adjust

Maintenance

Section for proper gap meas-

urement, or corrective action for improper

gap.)

J. See Section on

Electrical Connection of

Brake

.

K. Assemble housing and shaft assembly, rotat-

ing shaft (35) to engage key (35K) into hub

keyway. Be sure housing is assembled with

manual release on right hand (solenoid) side

(looking at output shaft side) or release lever

(148) will not latch. Replace housing bolts

and tighten evenly to 118 lb-ft of torque.

L. Remove access plug (7P). Insert a 3/16

″

hex wrench and tighten the two set screws

to 290 in-lb. (set screws are located 120

°

either side of the keyway).

M. For reducer application, mount and secure

brake/motor combination to mounting face of

reducer.

For alignment when brake shaft is direct-con-

nected to another shaft by a coupling refer to

coupling manufacturer

′s suggested proce-

dure. Side or overhung load is not permitted.

Consult factory for reversing applications.

II. Electrical Connection of Brake

CAUTION 1: Inverter Motor and Special

Control Systems. This brake contains a single

phase AC coil that requires instantaneous

power within

± 10% of rating at the coil. A sepa-

rate power source is required when this brake

is used in conjunction with a motor or control

system that limits voltage or current input (i.e.

inverter motors) or causes a ramping of the

power supply.

Note 1:

Be sure lead wires to coil are not tight

or pinched, and that leads will not be rubbed by

friction disc, trapped between solenoid plunger

and frame, caught between lever arm and end-

plate, or by linkage.

Note 2: See figure 3 for dual voltage coil con-

nection and connect to any two leads of single

or three-phase motor of the same voltage. The

brake can also be wired to external switch con-

tacts providing proper voltage other than that

used to control the motor. Normally, the motor

and brake contacts are interlocked.

Note 3: To use a 230 volt coil (or a 230/460

dual voltage coil connected for 230 volts) with a

230/460 dual voltage three-phase motor, the

brake leads are connected across two motor

terminals as shown, or other equivalent combi-

nations. If a 230 volt brake coil is

2

1 Friction Disc - Vertical Above

Item

No.

No.

Req.

Description

1

3

Blue Vertical Push-in Spring

1

Figure 2A

Figure 2B

2 Friction Discs - Vertical Above

Item

No.

No.

Req.

Description

1

3

Plain Vertical Push-in Spring

2

3

Red Vertical Push-in Spring

2

1

Figure 2C

2 Friction Discs - Vertical Below

Endplate

Item

No.

No.

Req.

Description

1

3

Blue Vertical Push-in Spring

2

3

Red Vertical Push-in Spring

2

1