Heating cable installation – King Electric SRP self-reg, preassembled User Manual

Page 2

Pipe

Type*

5

‘

10’ 15’ 20’ 25’ 30’ 35’ 40’ 45’ 50’ 55’ 60’ 65’ 70’ 75’ 80’ 85’ 90’ 95’

100’

½”

M

A

B

C

D

E

E

E

E

E

E

F

F

F

F

F

G

G

G

G

G

P

A

B

C

D

E

E

E

E

E

F

F

F

F

F

G

G

G

G

G

G

1”

M

A

B

C

D

E

E

E

E

E

E

F

F

F

F

F

G

G

G

G

G

P

B

B

C

D

E

E

E

E

E

F

F

F

F

F

G

G

G

G

G

G

1 ½”

M

A

B

C

D

E

E

E

E

E

E

F

F

F

F

F

G

G

G

G

G

P

B

C

D

E

E

E

E

F

F

G

G

G

G

G

-

-

-

-

-

-

2”

M

A

B

C

D

E

E

E

E

E

F

F

F

F

F

F

G

G

G

G

G

P

B

C

E

E

E

F

F

G

G

G

G

-

-

-

-

-

-

-

-

-

2

½”

M

A

C

C

D

E

E

E

E

E

F

F

F

F

F

G

G

G

G

-

-

P

B

D

E

E

F

F

F

G

G

-

-

-

-

-

-

-

-

-

-

-

A

SRP12-6

B

C

D

E

F

G

SRP12-18

SRP12-24

SRP12-50

SRP12-75

SRP12-100

SRP12-12

Heating Cable Selection Table for Pipe Freeze Protection

* Type: M = Metal Pipe, P = Plastic Pipe

- Add 1 foot to the cable length for each valve or spigot.

- Chart is based on the lowest outside temperature of 0

º

F (-18

º

C) with a minimum of

½” thick insulation. Use 1” insulation for protection in temperatures down to -20

º

F (-29

º

C).

GENERAL NOTES

1. Verify that the heating cable is the correct length, wattage and

voltage prior to installation.

2. All welding, hydrostatic testing, and painting of the pipe

should be completed before the heating cable installation.

3. The piping system must be inspected to ensure that it is clean,

dry and has no sharp or jagged edges that could potentially

damage the heating cable.

4. Do not install the heat tracing before completion of the entire

piping system.

5. The cables must be installed a minimum of 10 inches away

from wood or any other combustible materials.

6. The minimum cable bending radius is 1/2 inch.

PREPARE FOR INSTALLATION

1.

Store the heating cable in a clean, dry place.

2.

Perform a pressure test on the pipe prior to cable installation.

3. Remove any sharp surfaces on the pipe that could potentially

damage the outer jacket of the heating cable.

4. Walk the pipe system and plan the routing of the heating cable

on the pipe.

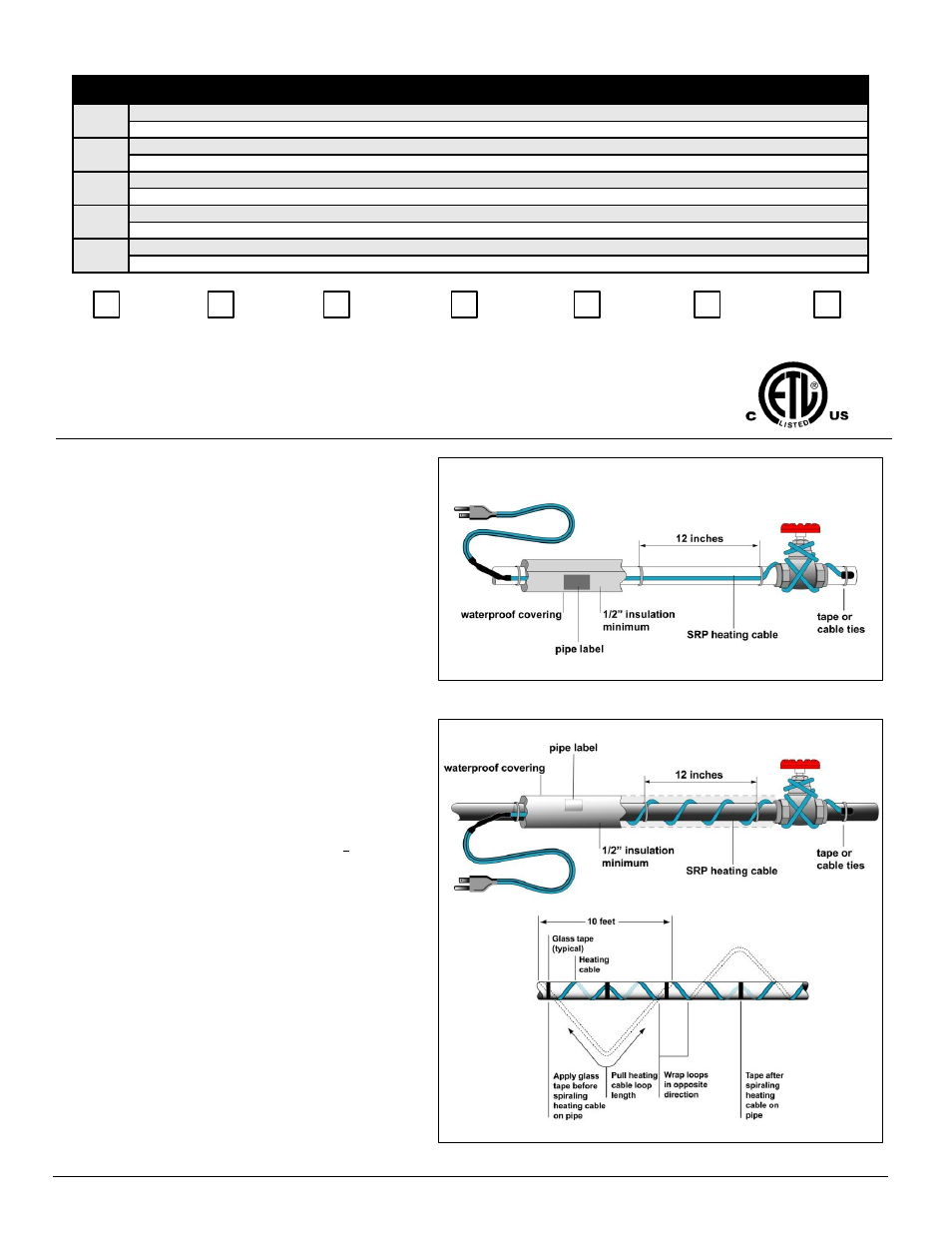

ATTACH THE HEATING CABLE TO THE PIPE

1

. Verify pipe to be traced is completely dry.

2. For straight tracing, install the heating cable on a the lower

half of the pipe; for example, in the 4 o

’clock

or 8 o

’clock

position as shown

in Figure

1.

3. For spiral tracing, install the cable as shown

in Figure 2.

4. Install the extra heating cable required for valves, flanges,

etc.

5. When applying spiral tracing, begin by suspending a loop of

cable every 10 feet as shown in Figure 2. To determine the

loop length, divide the length of pipe length and multiply by

10.

6.

For example, if you are using a 50 ft heating cable on a 40

foot pipe, leave a 12 foot loop of heating cable at every 10-foot

section of pipe. Grasp the loop in its center and wrap it around

the pipe. Even out the distance between spirals by sliding the

wraps along the pipe. Use glass tape (SRK03) to secure the

center of the loop to the pipe.

7. Fasten

the heating cable to the pipe at 1 foot intervals using

SRK03 fiberglass tape or nylon cable ties. Do not use vinyl

electrical tape, duct tape, metal bands or wire.

8. If there is excess cable at the end of the pipe, double

remaining cable back

along the pipe.

Heating Cable Installation

Figure 1: Straight Tracing

Figure 2: Spiral Tracing

Rev 8.19.12

www.king-electric.com

2