Water information, Operating steam pressure – American Dryer Corp. T20 User Manual

Page 22

22

JLA Limited

113428-9

!

!

!

!

!

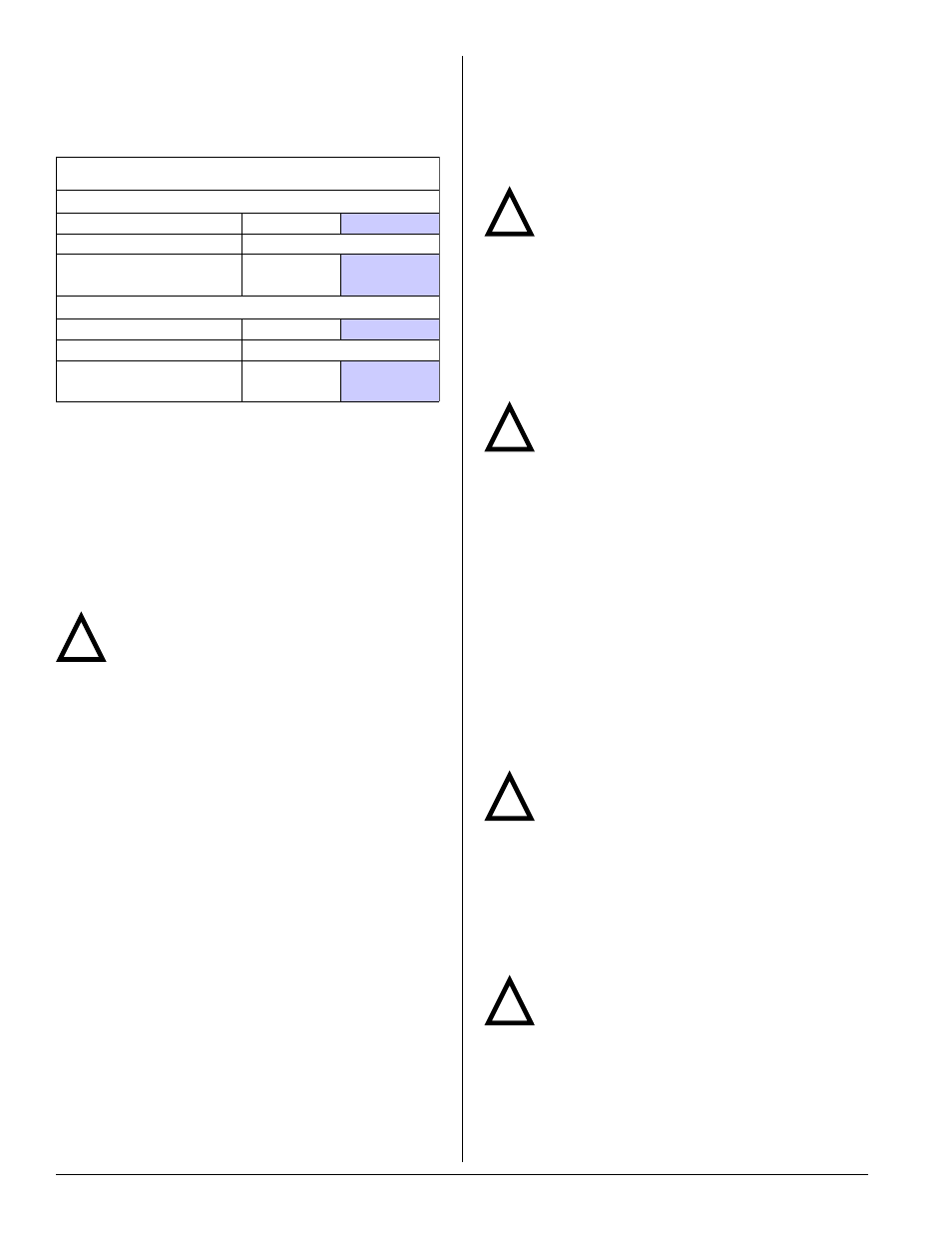

Steam Requirements – High Pressure

Inlet ---------- 1/2” N.P.T. supply line connection

1 at top manifold

Return ------- 1/2” N.P.T. return line connection

1 at bottom manifold

Shaded areas are stated in metric equivalents

* The minimum operating pressure for optimum results is 100 psig (689.47

kPa).

Installation Instructions

To ensure an adequate supply of steam is provided, be sure

that the steam supply lines and steam return lines are sized

and laid out as stipulated in this manual. Inadequate steam

supply lines and steam return lines or improper steam plumbing

will result in poor performance and can cause component

failure. Clean, dry steam must be provided to the dryer.

Important

Steam coil failure due to water hammer by wet

steam will void the warranty.

The presence of condensate in the steam supply line will cause

water hammer and subsequent heat exchanger (steam coil)

failure. The steam supply connection into the main supply

line must be made with a minimum 10-inch (25.4 cm) riser.

This will prevent any condensate from draining towards the

dryer.

The steam supply line to the dryer must include a 12-inch

(30.48 cm) riser along with a drip trap and check valve. This

will prevent any condensate from entering the steam coil.

Flexible hoses or couplings must be used. The dryer vibrates

slightly when it runs and this will cause the steam coil

connections to crack if they are hard piped to the supply and

return mains.

Shutoff valves for each dryer should be installed in the supply

line, return line, and drip trap return line. This will allow the

dryer to be isolated from the supply main and the return main

if the dryer needs maintenance work.

Install an inverted bucket steam trap and check valve at least

12-inches (30.48 cm) below the steam coil as close to the coil

as possible. A trap with a minimum capacity of 100 lb (45.35

kg) of condensate per hour at 125 psi (8.62 bar) is needed for

each unit. (Based on 2 times the steam consumption per hour.)

The supply line and the return line should be insulated. This

will save energy and provide for the safety of the operator and

maintenance personnel.

Operating Steam Pressure

T20 Stack

Maximum 150 psig

*

1.0 MPa

Heat Input (Normal Load)

1.2

Bhp

Consumption (Approximate)

@ 125 psi (8.6 bar)

45 lb/hr

20.41 kg/hr

T30 Stack

Maximum

150 psig

*

1.0 MPa

Heat Input (Normal Load)

1.75

Bhp

Consumption (Approximate)

@ 125 psi (8.6 bar)

63 lb/hr

28.58 kg/hr

Water pockets in the supply line, caused by low points, will

provide wet steam to the coil possibly causing steam coil

damage. All horizontal runs of steam supply piping should be

pitched 1/4-inch (6.35 mm) for every 1 foot (0.31 meters) back

towards the steam supply header causing the condensate in

the line to drain to the header. Install a bypass trap in any low

point to eliminate wet steam.

Important

Flexible hoses/couplings must be used. Coil failure

due to hard plumbing connections will void the

warranty.

Water Information_____________________

Before You Start

Check Local Codes and Permits

Call your local water company or the proper municipal authority

for information regarding local codes.

Important

It is your responsibility to have all plumbing

connections made by a qualified professional to

ensure that the plumbing installation is adequate and

conforms to local, state, and federal regulations or codes.

It is the installer’s or owner’s responsibility to see that the

required water pressure, pipe size, or connections are

provided. The manufacturer assumes no responsibility if the

fire suppression system is not connected, installed, or

maintained properly.

Installation

Water Supply

The fire suppression system must be supplied with a minimum

water pipe size of 1/2-inch (12.7 mm) and be provided with 40

psi +/- 20 psi (2.75 bar +/- 1.37 bar) of pressure.

If the rear area of the dryer or the water supply is located in an

area where it will be exposed to cold/freezing temperatures,

provisions must be made to protect these water lines from

freezing.

Warning

If the water in the supply line or water solenoid

valve freezes, the fire suppression system will be

inoperative!!

Water Connections

The water connection is made to the 3/4”-11.5 NH hose

adaptor, which is shipped in the tumbler and must be installed

to the 1/2” N.P.T. water connection, located at the upper rear

of the dryer. A flexible supply line/coupling must be used in an

effort to avoid damaging the electric water solenoid valve.

Note

The 3/4”-11.5 NH is a standard hose coupling

screw thread. It is not to be confused with 3/4”

N.P.T. The sealing of an NH connection is made with a

washer opposed to the mating threads of an N.P.T.

assembly. The 2 thread designs are not compatible.

It is recommended that a filter or strainer be installed in the

water supply line.