Electrical information – American Dryer Corp. T20 User Manual

Page 13

113428-9

Telephone 01422 822282

13

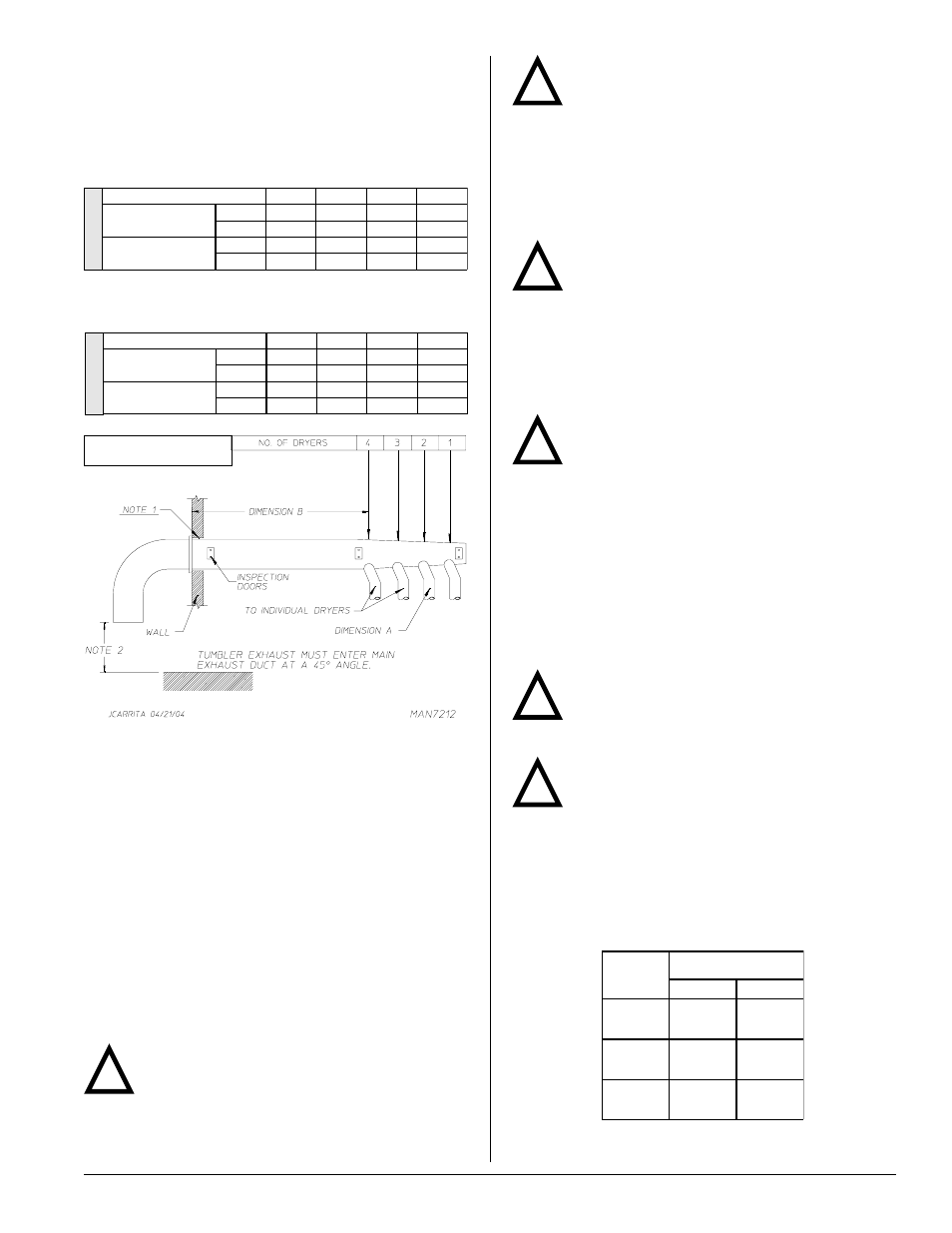

The illustration below shows the minimum cross-sectional area

for multiple dryer round or square venting. These figures must

be increased if the main duct run from the last dryer to where

it exhausts to the outdoors is longer than 12 feet (3.656 meters)

or has more than 1 elbow in it.

Multiple Dryer Venting with 8-Inch (20.32 cm) Diameter

460 cfm (13.03 cmm) Exhaust Connections at Common Duct

Multiple Dryer Venting with 8-Inch (20.32 cm) Diameter

720 cfm (20.39 cmm) Exhaust Connections at Common Duct

NOTE 1 Opening from combustible materials must be 2-inches (5.08 cm) larger

than the duct (all the way around). The duct must be centered within

this opening.

NOTE 2 Distance should be 2 times the diameter of the duct to the nearest

obstruction.

Electrical Information_________________

Electrical Requirements

All electrical connections must be made by a properly licensed

and competent electrician. This is to ensure that the electrical

installation is adequate and conforms to local, state, and

national regulations or codes of the country of origin. In the

absence of such codes, all electrical connections, materials,

and workmanship must conform to the applicable requirements

of the National Electrical Code ANSI/NFPA NO. 70-LATEST

EDITION or in Canada, the Canadian Electrical Codes Parts

1 & 2 CSA C22.1-1990 or LATEST EDITION.

Important

Failure to comply with these codes or ordinances,

and/or the requirements stipulated in this manual

can result in personal injury or component failure.

A = 8-inches (20.32 cm)

B = 12 feet (3.656 meters)

NUMBER OF DRYERS

4

3

2

1

MINIMUM CROSS-

SECTIONAL AREA

SQ IN

120

80

80

54

SQ CM

774.2

516.1

516.1

348.4

MINIMUM ROUND

DUCT DIAMETER

IN

12

10

10

8

CM

30.48

25.4

25.4

20.32

T20 Stack

NUMBER OF DRYERS

4

3

2

1

MINIMUM CROSS-

SECTIONAL AREA

SQ IN

164

120

80

54

SQ CM

1058

774.2

516.1

348.4

MINIMUM ROUND

DUCT DIAMETER

IN

14

12

10

8

CM

35.56

30.48

25.4

20.32

T30 Stack

Note

Component failure due to improper installation will

void the warranty.

Each pocket should be connected to an independently

protected branch circuit. The dryer must be connected with

copper wire only. Do not use aluminum wire, which could cause

a fire hazard. The copper conductor wire/cable must be of

proper ampacity and insulation in accordance with electric

codes for making all service connections.

Note

The use of aluminum wire will void the warranty.

An individual ground circuit must be provided to

each pocket, do not daisy chain.

Component failure due to improper voltage application will

void the warranty.

The manufacturer reserves the right to make changes in

specifications at any time without notice or obligation.

Important

A separate protected circuit must be provided to

each pocket.

It is necessary to have a power disconnect for each pocket.

These disconnects must be located within 9 meters of the

unit and also be identified as being one of two power

sources supplying a dryer.

The dryer must be connected to the electric supply shown

on the data label. In the case of 208 VAC or 240 VAC, the

supply voltage must match the electric service specifications

of the data label exactly.

The wire size must be properly sized to handle the related

current.

Warning

208 VAC and 240 VAC are not the same. Any

damage done to dryer components due to improper

voltage connections will automatically void the warranty.

Warning (Gas Models Only)

Dryers built for use with a voltage between 200 and

240 must verify the input voltage during installation.

If the nominal voltage is outside of the medium tolerances

shown on the diagram below, adjust the autotransformers,

located near the burner assemblies. To adjust the

autotransformer wiring, place the red wire on the

appropriate tap (HIGH, MED, LOW) of the autotransformer.

For additional wiring details, refer to the electrical diagram

located on the inside of the control panel.

!

!

!

TERM

LINE VOLTAGE

50 Hz

60 Hz

HIGH

260

226

283

249

MED

239

208

260

230

LOW

217

189

236

208

!

!

!