HTP MC120 User Manual

Page 43

43

LP-171 Rev. 4.10.14

Figure 23

– LP-171-R

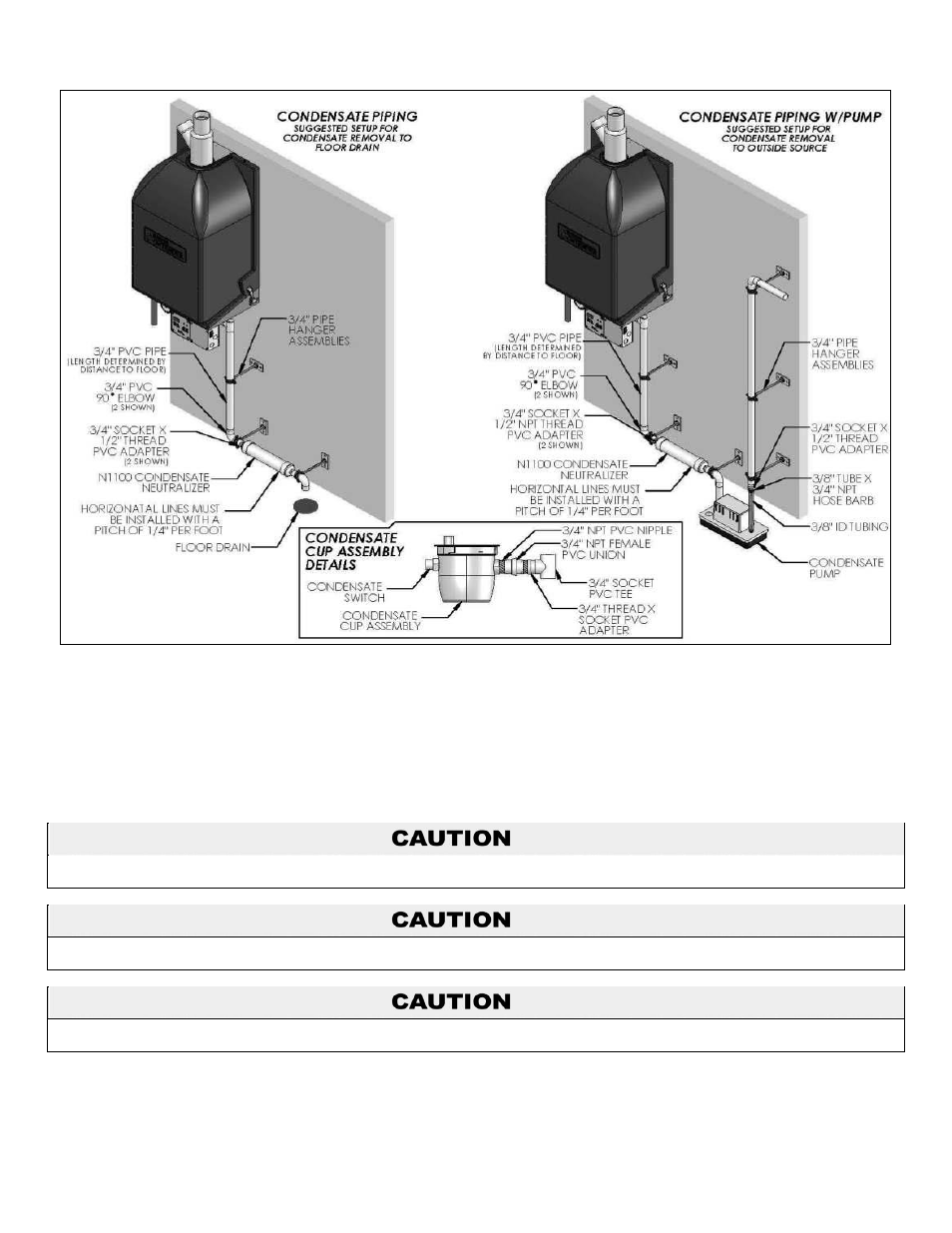

NOTES:

1. Condensate line must be pitched at least 1/4" per foot to properly drain. If this cannot be done, or a very long length of condensate hose is

used, you must

increase the condensate line to a minimum of 1” ID and place a tee in the line after the condensate neutralizer to properly

reduce vacuum lock in the drain line.

2. Plastic pipe should be the only material used for the condensate line. Steel, brass, copper, or other materials will be subject to corrosion or

deterioration.

3. NEVER install condensate lines outside. It is very important that the condensate line is not exposed to freezing temperatures or any type of

blockage. Damages due to frozen or blocked condensate lines ARE NOT covered by warranty.

4. Support of the condensate line may be necessary to avoid blockage of the condensate flow.

If using a condensate pump, select one approved for use with condensing heaters and furnaces. The pump should have an overflow

switch to prevent property damage from condensate spillage.

It is very important that the conden

sate piping be no smaller than ¾”. To prevent sagging and maintain pitch, condensate piping should

be supported with pipe supports, and

pitched ¼” per foot to allow for proper drainage.

The condensate line must remain unobstructed, allowing free flow of condensate. If condensate freezes in the line, or if line is

obstructed in any other manner, condensate can exit from the tee, resulting in potential water damage to property.