E. exhaust vent and intake pipe, F. prevent combustion air contamination – HTP MC120 User Manual

Page 13

13

LP-171 Rev. 4.10.14

E. EXHAUST VENT AND INTAKE PIPE

Vents must be properly supported. Heater exhaust and intake connections are not designed to carry heavy weight. Vent support

brackets must be within 1’ of the heater and the balance at 4’ intervals. Heater must be readily accessible for visual inspection for the

first 3’ from the heater.

The heater is rated ANSI Z21.13 Category IV (pressurized vent, likely to form condensate in the vent) and requires a special vent

system designed for pressurized venting.

You must also install air intake piping from outdoors to the heater flue adaptor. The resultant installation is categorized as direct vent

(sealed combustion). NOTE: To prevent combustion air contamination, see Table 1.

Exhaust and intake must terminate near each other and may be vented vertically through the roof or out a side wall. Exhaust vent and

intake piping methods are detailed in the Venting Section. Do not attempt to install the heater using any other means. Be sure to locate

the heater such that the exhaust vent and intake piping can be routed through the building and properly terminated. The exhaust vent

and intake piping lengths, routing and termination method must all comply with the methods and limits given in the venting section.

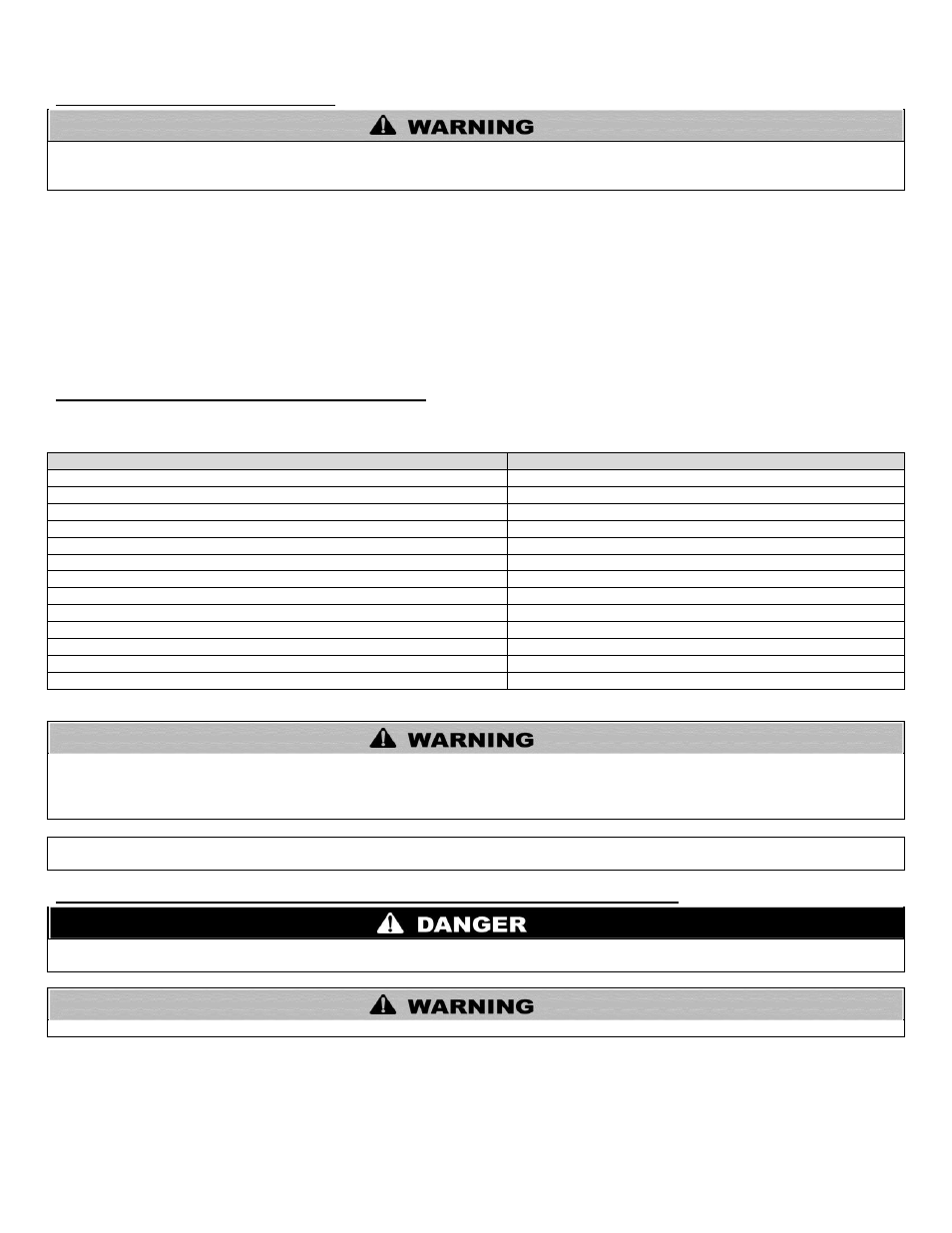

F. PREVENT COMBUSTION AIR CONTAMINATION

Install intake air piping for the heater as described in the Venting section. Do not terminate exhaust in locations that can allow

contamination of intake air.

PRODUCTS TO AVOID

AREAS LIKELY TO HAVE CONTAMINANTS

Spray cans containing fluorocarbons

Dry cleaning/laundry areas and establishments

Permanent wave solutions

Swimming pools

Chlorinated waxes/cleaners

Metal fabrication plants

Chlorine-based swimming pool chemicals

Beauty shops

Calcium chloride used for thawing

Refrigeration repair shops

Sodium chloride used for water softening

Photo processing plants

Refrigerant leaks

Auto body shops

Paint or varnish removers

Plastic manufacturing plants

Hydrochloric or Muriatic acid

Furniture refinishing areas and establishments

Cements and glues

New building construction

Antistatic fabric softeners used in clothes dryers

Remodeling areas

Chlorine-type bleaches, laundry detergents, and cleaning solvents

Garages and workshops

Adhesives used to fasten building products

Table 1 - Contaminant Table

You must pipe outside air to the heater air intake. Ensure that the intake air will not contain any of the contaminants listed in Table 1.

For example, do not pipe intake near a swimming pool. Also, avoid areas subject to exhaust fumes from laundry facilities. These areas

always contain contaminants. Contaminated air will damage the heater, resulting in possible substantial property damage, severe

personal injury, or death.

G. REMOVING AN EXISTING HEATER FROM AN EXISTING COMMON VENT SYSTEM

Do not install the heater into a common vent with any other appliance. This will cause flue gas spillage or appliance malfunction,

resulting in possible substantial property damage, severe personal injury, or death.

Failure to follow all instructions can result in flue gas spillage and carbon monoxide emissions, causing severe personal injury or death.

When removing an existing heater, follow the steps below with each appliance remaining connected to the common venting system in

operation, while other appliances remaining connected to common venting system are not operating.

1. Seal any unused openings in the common venting system.

NOTE: DAMAGE TO THE HEATER CAUSED BY EXPOSURE TO CORROSIVE VAPORS IS NOT COVERED BY WARRANTY.

(Refer to the limited warranty for complete terms and conditions).