Danger – Harrington Hoists and Cranes (N)ERCC Hoist - ((N)ER1) User Manual

Page 8

8

3.5.4

Power Supply Cable Hoist Connection – The Power Supply Cable connects to the hoist via a 4-pin

(4P) plug and socket. Make this connection as follows:

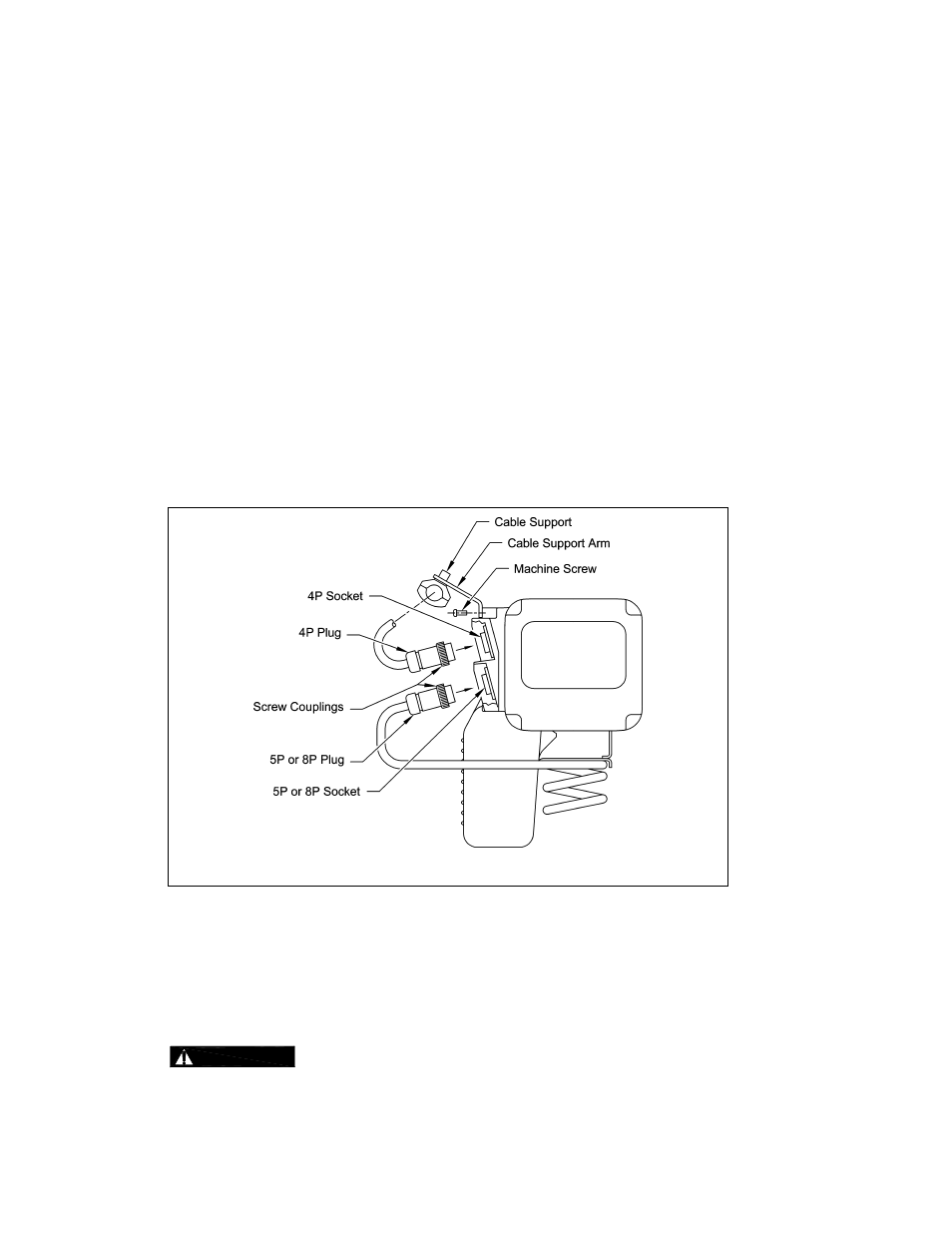

§ Refer to Figure 3-3.

§ Insert the 4P plug of the Power Supply Cable into the 4P Socket on the hoist and hand tighten the

screw coupling.

§ Install the Cable Support Arm (pre-installed on the Power Supply Cable) on to the Socket Holder

using the pre-installed Machine Screws and Lock Washers.

Use care to avoid twisting or kinking the Power Supply Cable.

3.5.5

Power Supply Cable Installation – If the hoist is hook mounted to a fixed support ensure that the

Power Supply Cable is properly installed and supported between the hoist and the electrical

power supply.

If the host is installed on a manual trolley, then the Power Supply Cable must be installed along the

beam that the trolley runs on. For curved beams a special cable suspension system will be

needed, and this instruction does not apply. For straight beams install the Power Supply Cable as

follows:

§ Install a guide wire system parallel to the beam.

§ For a manual trolley the guide wire should be positioned slightly outside the hoist's Cable

Support as shown in Figure 3-3.

§ Use the Cable Trolleys supplied with the hoist to suspend the Power Supply Cable from the

guide wire. Space the Cable Trolleys every 5 feet.

Figure 3-3 Coiled Control Cable and Power Supply Cable Connections

3.5.6

Connection to Electrical Power Source - The red, white, and black wires of the Power Supply Cable

should be connected to an Electric Power Disconnect Switch or Circuit Breaker. This connection

should be made so that the hoist is phased properly. Refer to Section 3.6.11 of the EROM for

instructions on how to check for correct power supply phase connection.

3.5.7

Fuse/Breaker Capacity -The hoist's power supply should be equipped with overcurrent protection such

as fuses, which should be selected for 110% to 120% of total listed full load amperage, and should be

dual element time-delay fuses. Refer to the motor nameplate for the full load amperage draw.

3.5.8

DANGER

Grounding - An improper or insufficient ground connection creates an electrical

shock hazard when touching any part of the hoist or trolley. In the Power Supply Cable the ground wire

will be either Green with Yellow stripe or solid Green. It should always be connected to a suitable

ground connection. Do not paint the trolley wheel running surfaces of the beam as this can affect

grounding.