Harrington Hoists and Cranes CX Hand Chain Hoist User Manual

Page 5

Page 5 of 6

Table 5-4 Hoist Inspection Methods and Criteria – Continued

Item

Method

Criteria

Action

Load Sheave

Visual

Pockets of Load Sheave should be clean and free of significant wear.

Replace.

Warning Labels

Visual

Warning Labels should be affixed to the hoist and they should be legible. (see

Section 8.0, Figure Number 33

)

Replace.

Hoist Capacity

Label

Visual

The label that indicates the capacity of the hoist should be legible and securely

attached to the hoist.

Replace.

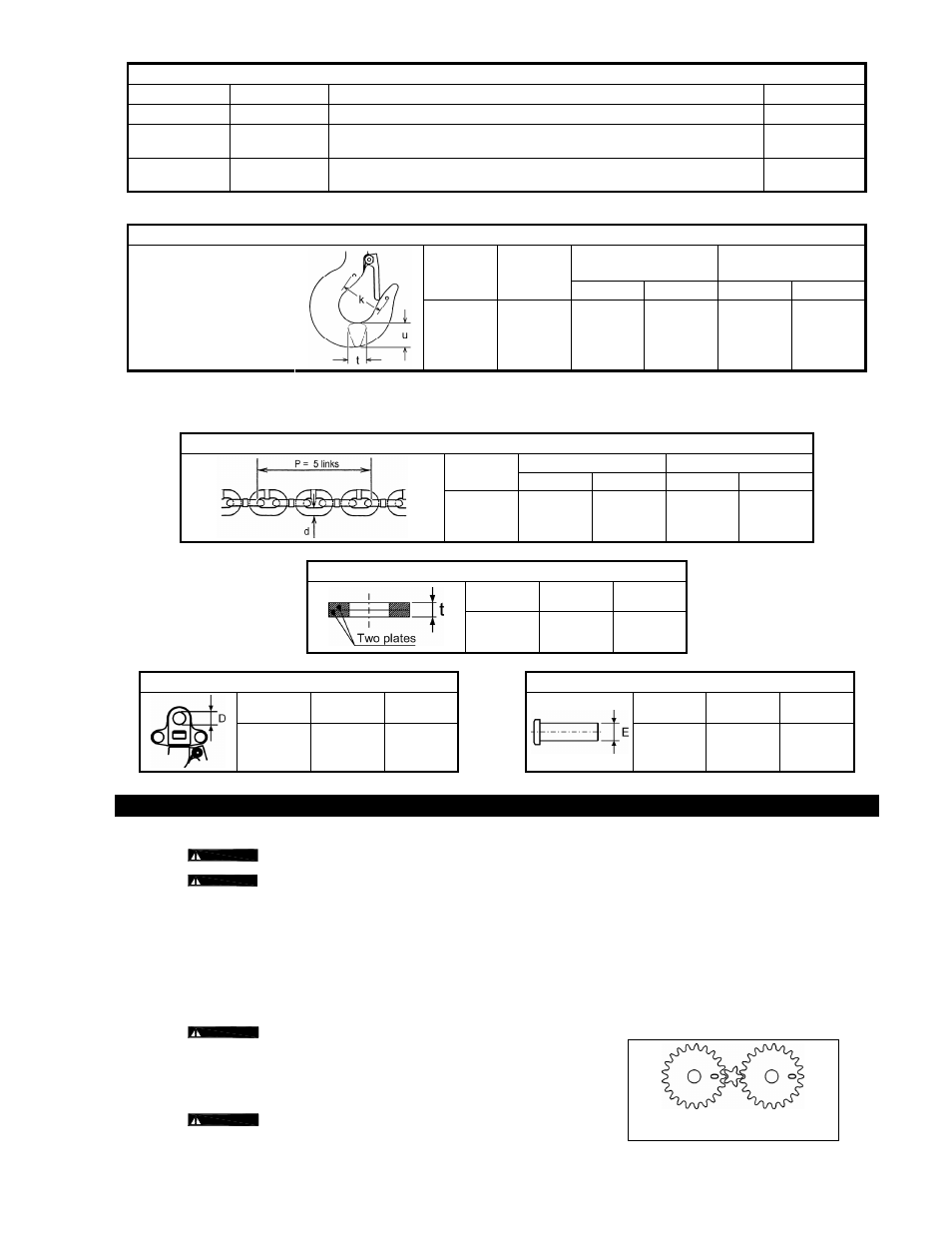

Table 5-5 Top Hook & Bottom Hook Dimensions

"u" Dimension

inch (mm)

"t" Dimension

inch (mm)

Product

Code

Nominal "k"

Dimension*

inch (mm)

Standard Discard Standard Discard

“k” Measured When New:

Top: ___________________

Bottom: _________________

CX003

1.35 (34.4)

0.49 (12.5)

0.47 (11.9)

0.43 (11.0)

0.41 (10.5)

* These values are nominal since the dimension is not controlled to a tolerance. The "k" dimension should be measured when the hook is

new - this becomes a reference measurement. Subsequent measurements are compared to this reference to make determinations about

hook deformation/stretch. See

Section 5-5

, “Hooks - Stretch”.

Table 5-6 Chain Wear Dimensions

"P" inch (mm)

"d" inch (mm)

Product

Code

Standard Discard Standard Discard

CX003

1.79 (45.5)

1.84 (46.8)

0.126 (3.2)

0.11 (2.9)

Table 5-7 Friction Plate Dimension "t"

Product

Code

Standard

inch (mm)

Discard

inch (mm)

CX003 0.20

(5.0)

0.18

(4.5)

Table 5-8 Top Pin Hole Dimensions "D"

Table 5-9 Top Pin Dimension "E"

Product

Code

Standard

inch (mm)

Discard

inch (mm)

Product

Code

Standard

inch (mm)

Discard

inch (mm)

CX003 0.33

(8.3)

0.35

(8.8)

CX003

0.33 (8.3)

0.35 (8.8)

6.0 Maintenance

6.1 For hoist maintenance or storage, comply with the following points.

6.1.1

DANGER

Do not lubricate the friction plate of the mechanical brake.

6.1.2

CAUTION

Always ensure that lubricant is applied to the load chain,

the top pin, the hook necks, the hook latches and the

select lever. Refer to

Section 2.1.4

“Hoist Parts”.

Do not store the hoist under a load.

Remove any dirt or water on the hoist.

Store the hoist in a dry and clean area.

Possibility of corrosion on components of the hoist

increases for installations where salt air and high

humidity are present. Make frequent and regular

inspections of the hoist’s condition and operation.

Perform all inspections given in “

5.0 Inspection

” if

irregularity of the hoist is found after operation

6.2 Disassembly/Assembly

6.2.1 When re-assembling the hoist, refer to parts list figure in

Section 8.0

for the proper component placement and orientation.

6.2.2

CAUTION

Load Limiter – Do NOT attempt to disassemble or adjust the

Load Limiter built into the Hand Wheel Assembly. Replace the Hand wheel

as an assembly with a new, factory adjusted part

6.2.3 Gear timing – Installing the Gear #2's with the timing marks "O" oriented as

shown in

Figure 6-1

.

6.2.4

WARNING

Make certain the no-load end Load Chain is not twisted

when attached to the hoist body. See Section 2-1-4 for attachment point.

Figure 6-1 Gear Timing