Caution – Harrington Hoists and Cranes CX Hand Chain Hoist User Manual

Page 2

Page 2 of 6

• Maintain a firm footing or be otherwise secured when operating

the hoist.

• Check brake function by tensioning the hoist prior to each lift

operation.

• Use hook latches. Latches are to retain slings, chains, etc. under

slack conditions only.

• Make sure the hook latches are closed and not supporting any

parts of the load.

• Make sure the load is free to move and will clear all obstructions.

• Avoid swinging the load or hook.

• Make sure hook travel is in the same direction as shown on

controls.

•

Inspect the hoist regularly, replace damaged or worn parts, and

keep appropriate records of maintenance.

• Use the hoist manufacturer’s recommended parts when repairing

the unit.

• Lubricate load chain per hoist manufacturer’s recommendations.

• NOT allow your attention to be diverted from operating the hoist.

• NOT allow the hoist to be subjected to sharp contact with other

hoists, structures, or objects through misuse.

• NOT adjust or repair the hoist unless qualified to

perform such adjustments or repairs.

• NOT use the hoist load limiting or warning device to measure load.

• NOT operate except with manual power

• NOT permit more than one operator to pull on a single hand chain

at the same time. More than one operator is likely to cause hoist

overload.

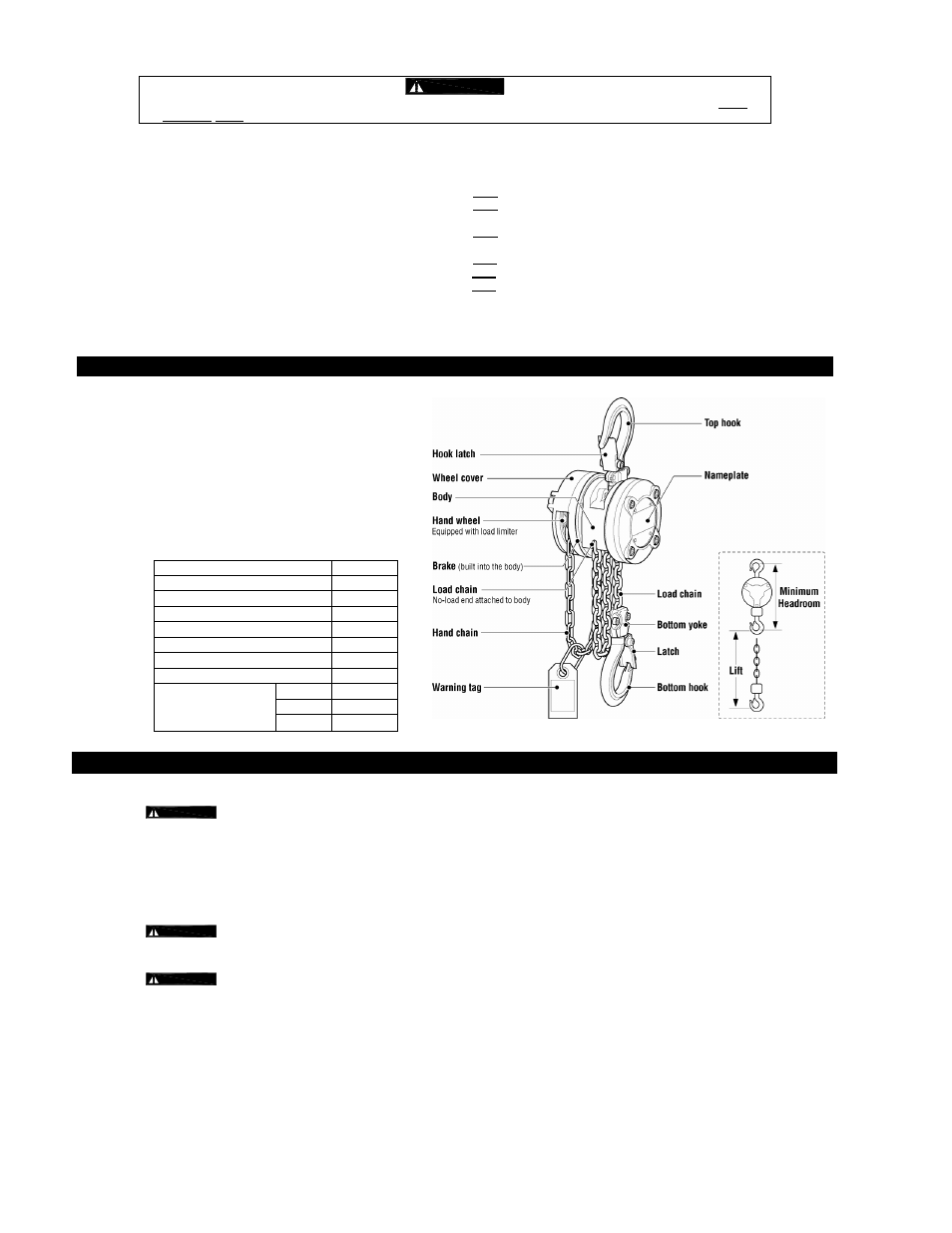

2.0 Technical Information

2.1 Specifications

2.1.1 Operating Conditions and Environment:

Temperature Range: -40° to +140°F

(-40° to +60°C)

Humidity: 100% or less

This is not underwater device.

Material: No special materials such as spark

resistant and asbestos.

Do Not Use: In an alkaline/acidic or an organic

solvent/explosive atmosphere.

2.1.2 Hoist

Specifications:

Product Code

CX003

Capacity (Ton)

1/4

Headroom C (in.)

8.5

Standard Lift (ft)

8, 10 or 20

Pull to Lift Rated Load (lbs)

33

Overhaul Ratio

34

Load Chain Dia. x Pitch (mm)

3.2 x 9.0

Chain Fall Lines

1

8 ft Lift

5.3

10 ft Lift

5.6

Net Weight (lbs)

20 ft Lift

9.5

2.1.3 Hoist

Parts

3.0 Preoperational Procedures

3.1 Mounting

Location

3.1.1

WARNING

Prior to mounting the hoist ensure that the suspension and the supporting structure are adequate to support the hoist

and its loads. If necessary consult a professional that is qualified to evaluate the adequacy of the suspension location and its

supporting structure. The maximum force which can be applied to the supporting structure is 2.4 times the rated capacity.

3.2 Mounting the Hoist

3.2.1 Manual Trolley – Follow instructions in Owner's Manual provided with the trolley.

3.2.2 Hook Mounted to a Fixed Location - Attach the hoist’s top hook to the fixed suspension point.

3.2.3

WARNING

Ensure that the fixed suspension point rests on the center of the hook’s saddle and that the hook’s latch is engaged.

3.3 Preoperational Checks and Trial Operations

3.3.1

WARNING

Confirm the adequacy of the rated capacity for all slings, chains, wire ropes and all other lifting attachments before

use. Inspect all load suspension members for damage prior to use and replace or repair all damaged parts.

3.3.2 Measure and record the “k” dimension of the top and bottom hook. See Table 5-4 under Section 5.0, “Inspection”.

3.3.3 Record the hoist's Code, Lot and Serial Number (from the name plate on the hoist; see Section 2.1.4) in the space provided on the

cover of this manual.

3.3.4 Ensure that the hoist is properly installed to a fixed point.

3.3.5 Ensure that all nuts and bolts are sufficiently fastened.

3.3.6 Confirm proper operation:

•

Before operating read and become familiar with Section 4 - Operation.

•

Before operating ensure that the hoist meets the Inspection, Testing and Maintenance requirements of ANSI/ASME B30.16.

•

Before operating ensure that nothing will interfere with the full range of the hoist’s operation.

CAUTION

Improper operation of a hoist can create a potentially hazardous situation which, if not avoided, could result in minor or

moderate injury, or property damage. To avoid such a potentially hazardous situation THE OPERATOR SHALL: