Harrington Hoists and Cranes CX Hand Chain Hoist User Manual

Page 3

Page 3 of 6

4.0 Operation

4.1 Introduction

4.1.1

WARNING

HOIST OPERATORS SHALL BE REQUIRED TO READ THE OPERATION SECTION OF THIS MANUAL, THE

WARNINGS CONTAINED IN THIS MANUAL, INSTRUCTION AND WARNING LABELS ON THE HOIST OR LIFTING SYSTEM,

AND THE OPERATION SECTIONS OF ANSI/ASME B30.16 and ANSI/ASME B30.10.

4.2 Lifting

and

Lowering

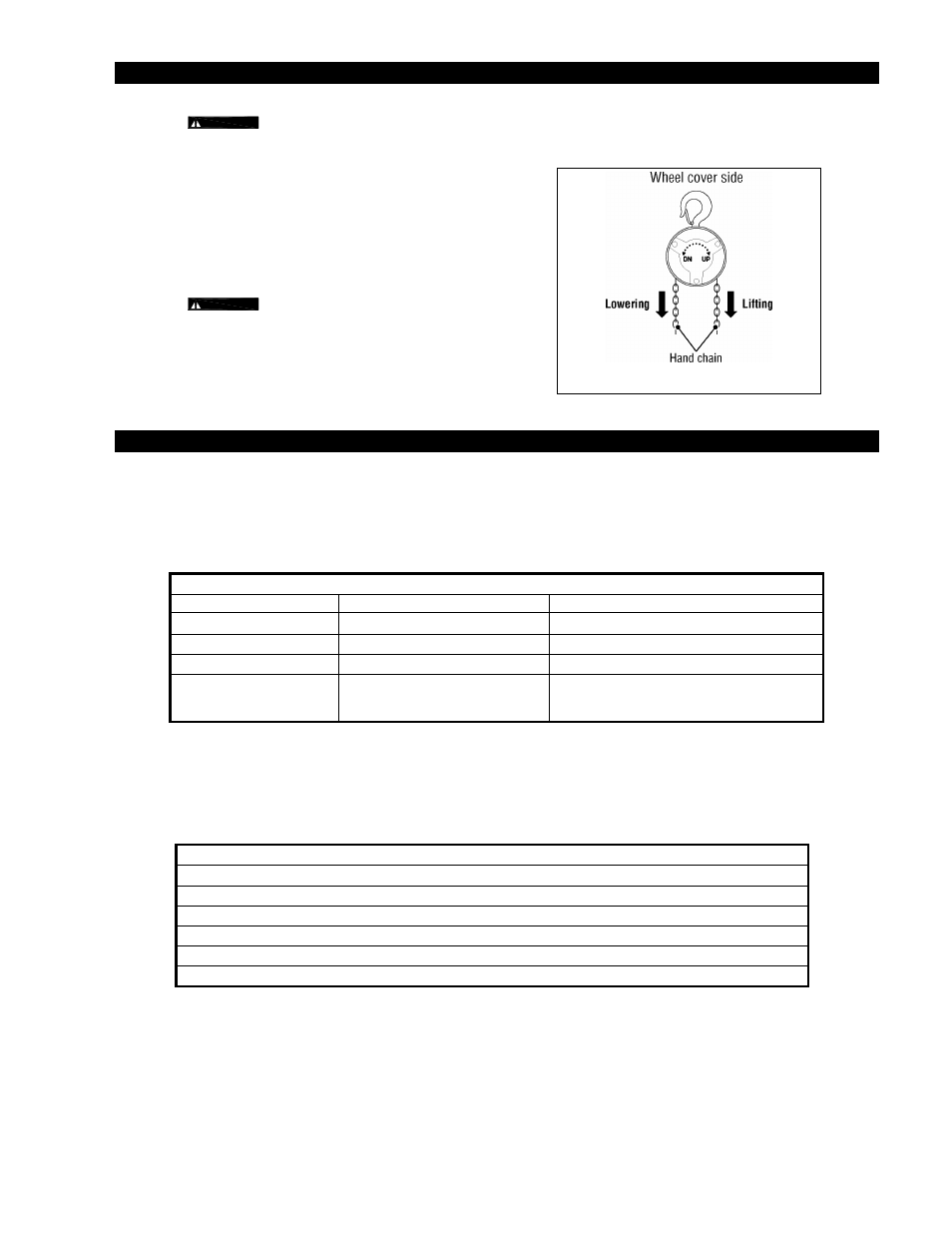

4.2.1 Refer to the arrows and text on the hand wheel cover –

see

Figure 4-1

.

4.2.2 To

LIFT the Load – When facing the hand wheel side of

the hoist, pull down on the RIGHT side hand chain.

4.2.3 To

LOWER the Load – When facing the hand wheel side

of the hoist, pull down on the LEFT side hand chain.

4.2.4

WARNING

This product is designed for a rated load to

be hoisted by pulling the hand chain with a force of 33 lb

(15kg) or less. Do NOT pull on the hand chain with a

force greater than 33 lb (15kgf). Stop using the hoist and

consult a qualified person if the a load of 1/4 Ton or less

cannot be lifted with a pull force of 33 lb (15kgf) or less.

Figure 4-1 Lifting and Lowering

5.0 Inspection

5.1 Initial

Inspection

–

Prior to initial use, all new, altered, or modified hoists shall be inspected by a designated person to ensure compliance

with the applicable provisions of this manual.

5.2 Inspection

Classification – The inspection procedure herein is based on ANSI/ASME B30.16. Inspections for hoists in regular service

are divided into FREQUENT and PERIODIC groups based upon the intervals at which inspection should be performed. The intervals in

turn are dependent upon the degree of service and usage the hoists are subjected to. The two general classifications are herein

designated as FREQUENT and PERIODIC, with respective intervals between inspections as defined in Table 4-1.

Table 5-1 Inspection Intervals

Service

FREQUENT Inspection

PERIODIC Inspection

Normal Service

Monthly

Yearly

Heavy Service

Weekly to Monthly

Semiannually

Severe Service

Daily to Weekly

Quarterly

Special or Infrequent Service

As recommended by a qualified

person before and after each

occurrence.

As recommended by a qualified person before

the first such occurrence and as directed by the

qualified person for any subsequent occurrences.

5.3 Frequent

Inspection

5.3.1 Inspections should be made on a FREQUENT basis in accordance with

Table 5-2

, “Frequent Inspection.” Included in these

FREQUENT Inspections are observations made during operation for any defects or damage that might appear between Periodic

Inspections. Evaluation and resolution of the results of FREQUENT Inspections shall be made by a designated person such that

the hoist is maintained in safe working condition.

Table 5-2 Frequent Inspection

All functional operating mechanisms for proper operation and adjustment, maladjustment and unusual sounds.

Hoist braking system for proper operation

Hooks and latches in accordance with ANSI/ASME B30.10

Hook latch operation

Load chain in accordance with

Section 5.5

Hoist support for damage

5.4 Periodic

Inspection

5.4.1 Inspections should be made on a PERIODIC basis in accordance with

Table 5-3

, “Periodic Inspection.” Evaluation and resolution of

the results of PERIODIC Inspections shall be made by a designated person such that the hoist is maintained in safe working

condition.

5.4.2 For inspections where load suspension parts of the hoist are disassembled, a load test per ANSI/ASME B30.16 must be performed

on the hoist after it is re-assembled and prior to its return to service.