Harrington Hoists and Cranes LX Mini Lever Hoist User Manual

Page 4

Page 4 of 6

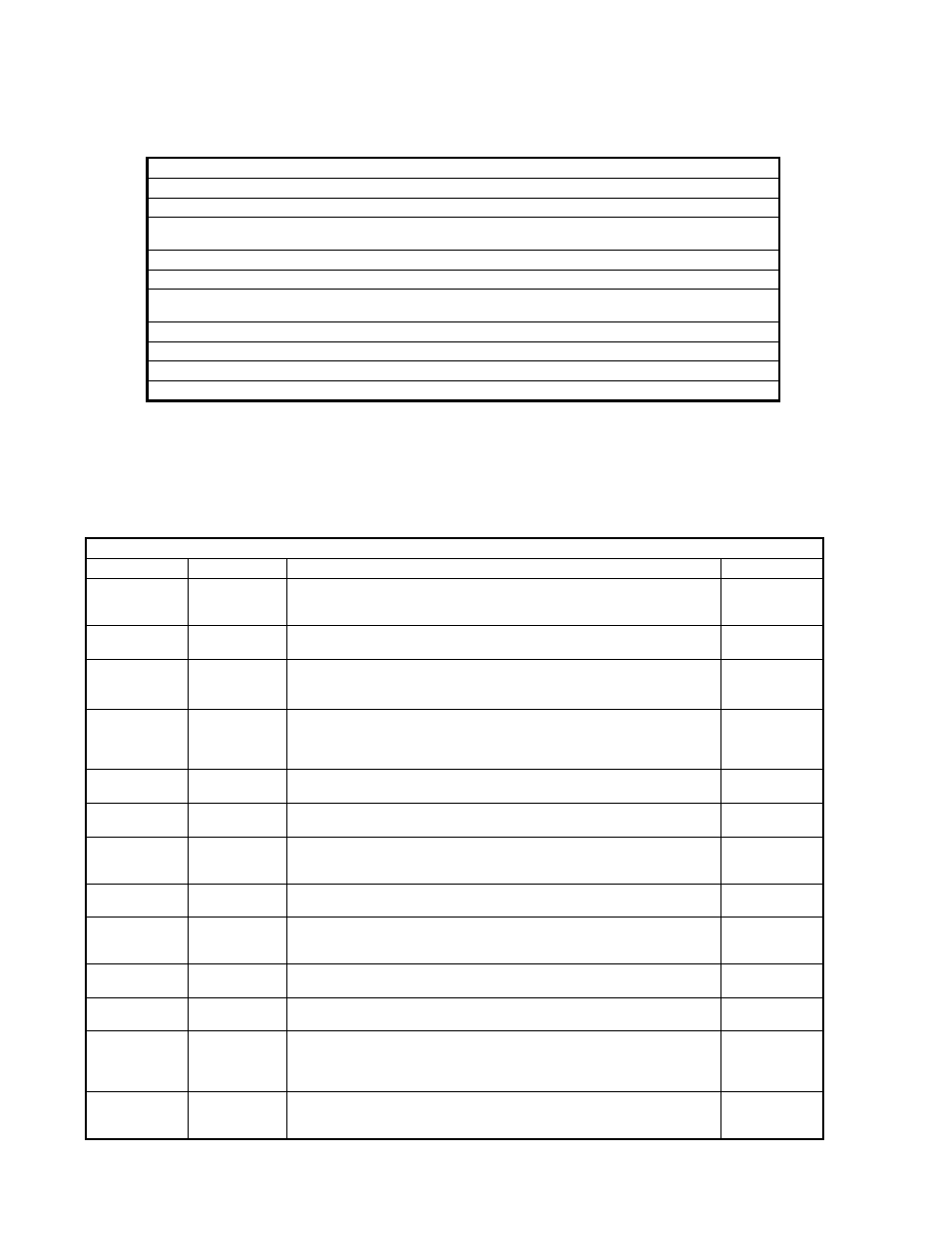

4.4 Periodic

Inspection

4.4.1 Inspections should be made on a PERIODIC basis in accordance with Table 4-2, “Periodic Inspection.” Evaluation and

resolution of the results of PERIODIC Inspections shall be made by a designated person such that the hoist is maintained in

safe working condition.

4.4.2 For inspections where load suspension parts of the hoist are disassembled, a load test per ANSI/ASME B30.21 must be

performed on the hoist after it is re-assembled and prior to its return to service.

Table 4-2 Periodic Inspection

Requirements of frequent inspection.

Evidence of loose bolts, nuts, or rivets.

Evidence of worn, corroded, cracked, or distorted parts such as suspension housing, chain attachments, yokes,

suspension bolts, shafts, gears, bearings, pins, rollers and locking and clamping devices.

Evidence of damage to hook retaining nuts or collars and pins, and welds or rivets used to secure the retaining members.

Evidence of damage or excessive wear of load sheave.

Evidence of worn, glazed or oil contaminated friction disks; worn pawls, cams or ratchet; corroded, stretched, or broken pawl

springs in brake mechanism.

Evidence of damage to supporting structure.

Function label on hoist for legibility.

Warning label properly attached to the hoist and legible (see Section 7, Fig. No. 37).

End connections of load chain stopper link.

4.5 Inspection Methods and Criteria

4.5.1 This section covers the inspection of specific items. The list of items in this section is based on those listed in ANSI/ASME

B30.21 for the Frequent and Periodic Inspection.

4.5.2 Frequent Inspection - Not intended to involve disassembly of the hoist. Disassembly for further inspection would be required

if only if frequent inspection results so indicate. Disassembly and further inspection should only be performed by a qualified

person trained in the disassembly and re-assembly of the hoist.

4.5.3 Periodic Inspection - Disassembly of the hoist is required. Disassembly should only be performed by a qualified person

trained in the disassembly and re-assembly of the hoist.

Table 4-3 Hoist Inspection Methods and Criteria

Item

Method

Criteria

Action

Functional

operating

mechanisms.

Visual, Auditory

Mechanisms should be properly adjusted and should not produce unusual sounds

when operated. Components should not be deformed, scarred or show significant

wear.

Repair or replace

as required.

Braking System

– Components

Visual

Brake Pawl, Pawl Shaft, Pawl Spring, Friction Disc and Ratchet Disc should not

be deformed scarred or show significant wear.

Replace

Braking System

– Friction Plate

Visual, Measure

The surface of the friction plate should be free of grease, oil, scars, gouges and

wear and have uniform thickness. The thickness of both plates together should

not be less than the discard value listed in Table 4-6.

Replace

Housing

Mechanical and

Lifting System –

Components

Visual, Auditory,

Function

Hoist components including load blocks, suspension housing, chain attachments,

clevises, yokes, suspension bolts, shafts, gears, bearings, pins and rollers should

be free of cracks, distortion, significant wear and corrosion. Evidence of same

can be detected visually or via detection of unusual sounds during operation.

Replace.

Hooks –

Condition

Visual

Should be free of gouges, dents, weld splatter, significant corrosion, twists,

deformations, significant wear, dirt and grime. Hook should swivel freely.

Replace.

Hooks – Fretting

wear

Measure

The "u" and "t" dimensions should not be less than the discard value listed in

Table 4-4.

Replace.

Hooks – Stretch

Measure

The "k" dimension should not be greater than 1.05 times that measured and

recorded at the time of purchase (See Section 3.1). If recorded "k" values are not

available for hooks when new, use nominal "k" values from Table 4-4.

Replace.

Hooks – Hook

Latches

Visual, Function

Latch should not be deformed. Attachment of latch to hook should not be loose

or stiff. Latch spring should not be missing and should not be weak.

Replace.

Hooks – Yoke

Assembly

Visual

Should be free of significant rust, weld splatter, nicks, gouges. Holes should not

be elongated, fasteners should not be loose (Refer to figure in Section 7.0), and

there should be no gap between mating parts.

Torque or

replace as

required.

Yoke – Hole

Deformation

Visual, Measure

The "d" dimension of the chain pin hole and "D" dimension of the top pin hole

should not be greater than the discard value listed in Table 4-7.

Replace Hook

Set

Chain Pin & Top

Pin – Deformation

Visual, Measure

The chain pin and top pin should be free of scars or significant deformation. The

"d" and "D" dimension should not be less than discard value listed in Table 4-8.

Replace

Load Chain –

Surface

Condition,

Lubrication

Visual

Should be free of gouges, nicks, dents, weld splatter and corrosion. Links should

not be deformed, and should not show signs of abrasion. Surfaces where links

bear on one another should be free of significant wear. Entire surface should be

coated with lubricant and should be free of dirt and grime.

Replace (only

with load chain

listed in parts

list).

Load Chain –

Pitch and Wire

Diameter

Measure

The "P" dimension should not be greater than discard value listed in Table 4-5.

The "d" dimension should not be less than discard value listed in Table 4-5.

Replace (see

above). Inspect

load sheave.