Harrington Hoists and Cranes LX Mini Lever Hoist User Manual

Page 3

Page 3 of 6

3.2.3 How to Operate

D N

N

U P

Lever

Select lever

Chain knob

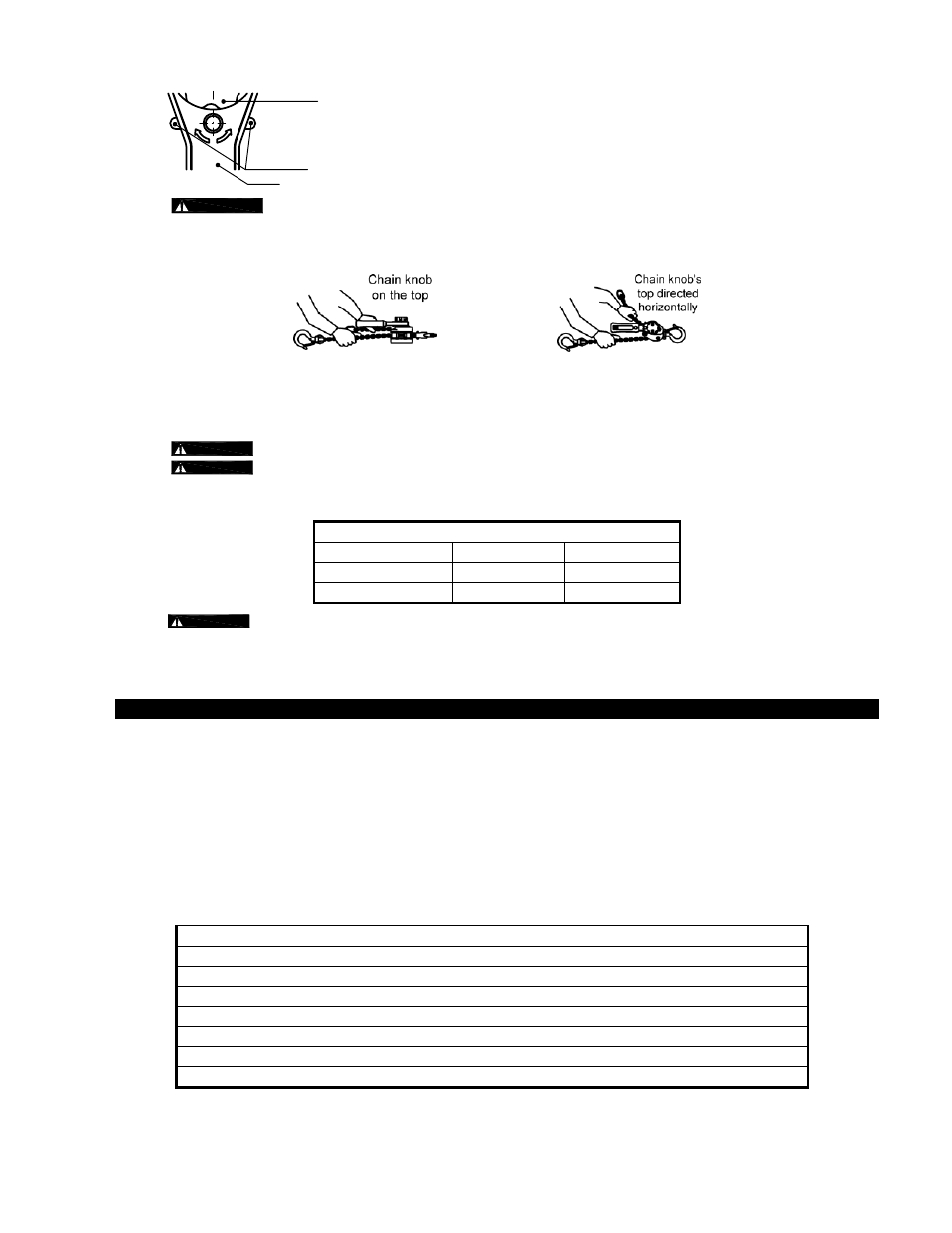

1. Move the select lever to the neutral (‘N’) position as shown in the left picture.

2. With the no-load side chain pulled lightly, turn the chain knob counterclockwise.

3. In this mode, the load chain can be pulled through the hoist to its required length.

If the hoist does not shift into free chaining mode, hold the no-load-side chain and make

some lowering operations to release the brake.

3.2.4

CAUTION

Do not pull the load chain suddenly in free chaining mode. Excessive pulling may set the brake and not allow the

chain to be moved. If this occurs the hoist must be reset.

3.2.5 Free chaining with the chain knob on the top as shown in Figure 3.1 may cause a braking force. In this case, direct the top of the knob

towards the horizontal side as shown in Figure 3.2 in free-chaining mode.

Figure 3-1

Figure 3-2

3.2.6 To reset the hoist for load operation, set the select lever to the lifting (‘UP’) or the lowering (‘DN’) position to eliminate the clearance

to the friction plate and operate the lever.

3.3 Lifting and Lowering Operation

3.3.1

DANGER

Do not operate the chain knob in lifting or lowering.

3.3.2

CAUTION

Before operating, make sure that the hoist is not in free chaining mode and set the select lever to the direction of load

movement desired, then ratchet the lever back and forth.

3.3.3 The following table shows select lever position and lever operation for lifting and lowering.

Table 3-1 Hoist Lever Operation

Select Lever Position

Lever Rotation

Load Movement

UP Clockwise

Lift

DN Counterclockwise

Lower

3.3.4

CAUTION

Under no-load or light load (approx. 6 ½ lbs.) conditions, if the load chain does not move, operate the lever while pulling slightly on

the load-side of the load chain. (Normal Operation)

If a lifting operation does not produce clicking sounds, the brake is released. Perform the lifting operation again with the load-side

chain pulled firmly until clicking sounds are heard.

4.0 Inspection

4.1 Initial

Inspection – prior to initial use, all new, altered, or modified hoists shall be inspected by a designated person to ensure

compliance with the applicable provisions of this manual.

4.2 Inspection

Classification – The inspection procedure herein is based on ANSI/ASME B30.21. Inspections for hoists in regular

service are divided into FREQUENT and PERIODIC groups based upon the intervals at which inspection should be performed. The

intervals in turn are dependent upon the degree of service and usage the hoists are subjected to. FREQUENT intervals range from

monthly to daily and PERIODIC intervals range from quarterly to yearly. Consult Harrington or ANSI/ASME B30.21 for the exact

interval criteria.

4.3 Frequent

Inspection

4.3.1 Inspections should be made on a FREQUENT basis in accordance with Table 4-1, “Frequent Inspection.” Included in these

FREQUENT Inspections are observations made during operation for any defects or damage that might appear between Periodic

Inspections. Evaluation and resolution of the results of FREQUENT Inspections shall be made by a designated person such

that the hoist is maintained in safe working condition.

Table 4-1 Frequent Inspection

All functional operating mechanisms for proper operation and adjustment, maladjustment and unusual sounds.

Hoist braking system for proper operation

Hooks and latches in accordance with ANSI/ASME B30.10

Hook latch operation

Load chain in accordance with Section 4.5

Hoist lever for bends, cracks, etc,

Hoist support for damage