Operation, Arc gouging, Wire welding-cv – Lincoln Electric AIR VANTAGE IM10065 User Manual

Page 27

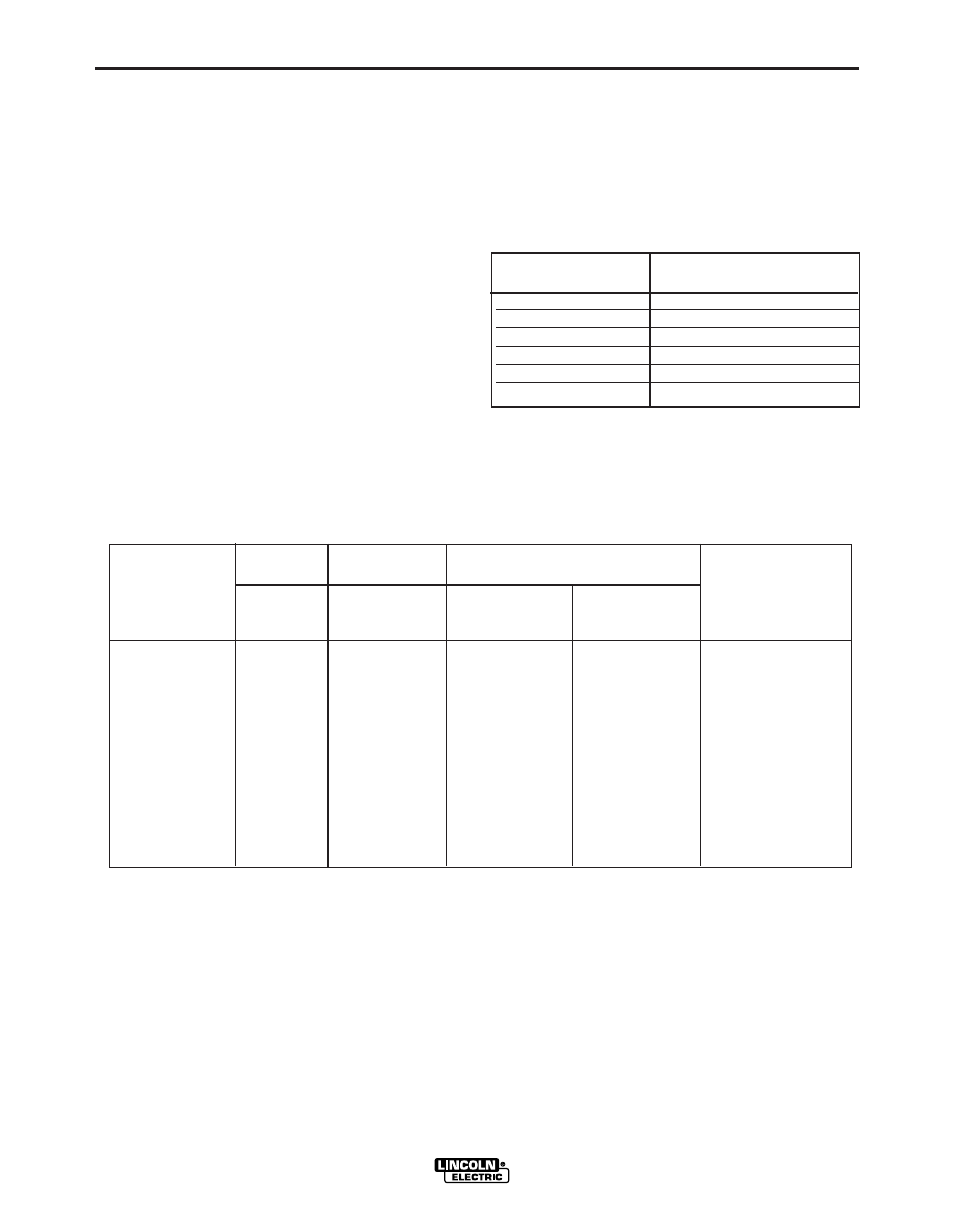

ARC GOUGING

For optimal performance when arc gouging, set the

AIR VANTAGE® 500 CUMMINS “WELD MODE”

switch to the “CC - STICK” position, and the “ARC

CONTROL” to 10.

Set the “OUTPUT” knob to adjust output current to the

desired level for the gouging electrode being used

according to the ratings in the following Table B.2.

NOTE: If desired the CV mode can be used for Arc Gouging.

* Maximum current setting is limited to the AIR VANTAGE® 500 CUMMINS

maximum of 575 Amps.

WIRE WELDING-CV

Connect a wire feeder to the AIR VANTAGE® 500

CUMMINS according to the instructions in INSTALLA-

TION INSTRUCTIONS Section.

The AIR VANTAGE® 500 CUMMINS in the ”CV-

WIRE” position, permits it to be used with a broad

range of flux cored wire (Innershield and Outershield)

electrodes and solid wires for MIG welding (gas metal

arc welding). Welding can be finely tuned using the

“ARC CONTROL”. Turning the ARC CONTROL clock-

wise from -10(soft) to +10(crisp) changes the arc from

soft and washed-in to crisp and narrow. It acts as an

inductance/pinch control.

The proper setting depends on the procedure and

operator preference. Start with the knob set at 0.

For any electrodes, including the above recommenda-

tions, the procedures should be kept within the rating

of the machine. For additional electrode information,

See www.lincolnelectric.com or the appropriate

Lincoln publication.

Carbon Diameter

Current Range (DC, elec-

trode positive)

1/8"(3.2mm)

30-60 Amps

5/32"(4.0mm)

90-150 Amps

3/16"9(4.8mm)

200-250 Amps

1/4"(6.4mm)

300-400 Amps

5/16"(8.0mm)

350-450 Amps

3/8"(10.0mm)

450-575 Amps*

TAbLE b.2

b-8

OPERATION

b-8

AIR VANTAGE® 500 CUMMINS

Table b.3 TYPICAL CURRENT RANGES

(1)

FOR TUNGSTEN ELECTRODES

(2)

DCEN (-)

DCEP (+)

Approximate Argon Gas Flow Rate

l/min (c.f.m.)

Tungsten

Electrode

1%, 2%

1%, 2%

TIG TORCH

Diameter

Thoriated

Thoriated

Aluminium

Stainless Steel

Nozzle

mm (in)

Tungsten

Tungsten

Size (4), (5)

.25 (0.010)

2-15

(3)

2-4 (3-8)

2-4 (3-8)

#4, #5, #6

.50 (0.020)

5-20

(3)

3-5 (5-10)

3-5 (5-10)

1.0 (0.040)

15-80

(3)

3-5 (5-10)

3-5 (5-10)

1.6 (1/16)

70-150

10-20

3-5 (5-10)

4-6 (9-13)

#5, #6

2.4 (3/32)

150-250

15-30

6-8 (13-17)

5-7 (11-15)

#6, #7, #8

3.2 (1/8)

250-400

25-40

7-11 (15-23)

5-7 (11-15)

4.0 (5/32)

400-500

40-55

10-12 (21-25)

6-8 (13-17)

#8, #10

4.8 (3/16)

500-750

55-80

11-13 (23-27)

8-10 (18-22)

6.4 (1/4)

750-1000

80-125

13-15 (28-32)

11-13 (23-27)

(1)

When used with argon gas. The current ranges shown must be reduced when using argon/helium or pure helium shielding gases.

(2)

Tungsten electrodes are classified as follows by the American Welding Society (AWS):

Pure

EWP

1% Thoriated

EWTh-1

2% Thoriated

EWTh-2

Though not yet recognized by the AWS, Ceriated Tungsten is now widely accepted as a substitute for 2% Thoriated Tungsten in AC and DC applica-

tions.

(3)

DCEP is not commonly used in these sizes.

(4)

TIG torch nozzle “sizes” are in multiples of 1/16ths of an inch:

# 4 =

1/4 in.

6 mm

# 5 =

5/16 in.

8 mm

# 6 =

3/8 in.

10 mm

# 7 =

7/16 in.

11 mm

# 8 =

1/2 in.

12.5 mm

#10 =

5/8 in.

16 mm

(5)

TIG torch nozzles are typically made from alumina ceramic. Special applications may require lava nozzles, which are less prone to breakage, but can-

not withstand high temperatures and high duty cycles.