Dr-1 fluid regulator - safety – Ransburg DR-1 Fluid Regulator 74151 User Manual

Page 7

4

DR-1 Fluid Regulator - Safety

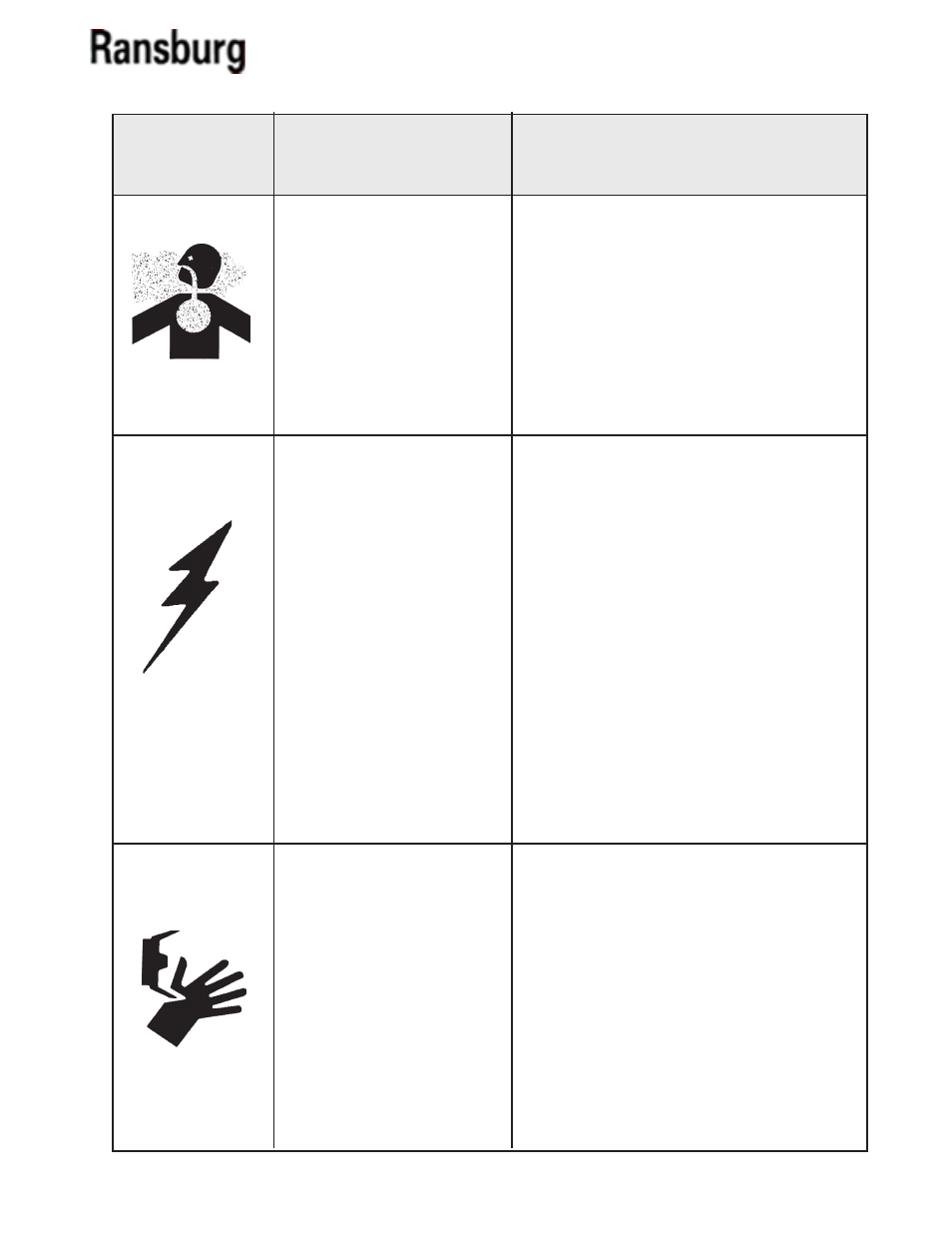

AREA

Tells where hazards

may occur.

HAZARD

Tells what the hazard is.

SAFEGUARDS

Tells how to avoid the hazard.

Spray Area /

High Voltage

Equipment

Personnel Safety/

Mechanical

Hazards

This is a high voltage device that

can produce electrical arcs capable

of igniting coating materials.

Parts being sprayed must be supported on conveyors

or hangers and be grounded. The resistance between

the part and ground must not exceed 1 megohm.

(Reference NFPA-33.)

A safe distance must be maintained between the parts

being coated and the atomizer bell. A distance of at least

1 inch for each 10 kV of power supply output voltage is

required at all times.

Parts must be supported so that they will not swing and

reduce the clearance specified above.

All electrically conductive objects in the spray area, with

the exception of those objects required by the process

to be at high voltage, must be grounded.

Unless specifically approved for use in hazardous loca-

tions, the power supply and other electrical equipment

must not be used in Class I, Division 1 or 2 locations.

The bell atomizer can rotate at

speeds up to 55,000 rpm. At these

speeds, the edge of the applicator

can easily cut into skin. Loose articles

of clothing can also be caught by the

rotating bell.

Personnel must stay clear of the bell whenever it is

rotating.

Before touching the bell, the turbine air must be shut

off.

If the bell has been rotating, allow at least two minutes

for it to come to a complete stop before touching it.

Toxic Substances

Certain material may be harmful if

inhaled, or if there is contact with

the skin.

Follow the requirements of the Material Safety Data

Sheet supplied by coating material manufacturer.

Adequate exhaust must be provided to keep the air free

of accumulations of toxic materials.

Use a mask or respirator whenever there is a chance of

inhaling sprayed materials. The mask must be compat-

ible with the material being sprayed and its concentra-

tion. Equipment must be as prescribed by an industrial

hygienist or safety expert, and be NIOSH approved.

LN-9223-00.10