Ransburg, Mma-303 test station - introduction – Ransburg MMA-303 Direct_Ind Test Stand User Manual

Page 10

Ransburg

5

10

80

90

10

0

11

0

12

0

13

0

15

20

40

50

60

70

5

10

80

90

10

0

11

0

12

0

13

0

15

20

40

50

60

70

ATOMIZER

SPEED

TURBINE

x1000 RPM

DRIVE

BRAKE

TEST POINTS

2

1

ATOMIZER

+

+

-

-

ENABLE3

ENABLE1

ENABLE4

ENABLE2

SPEED SELECT

SPEED SELECT(X1000)

ON

ON

SPEED

ENTER

SELECT

ATOMIZER

1

2

3

4

CPU

ACTIVE

RDY

ON

ADJ

KV

A

REMOTE

LOCAL

OFF

SET

OVER

FAULT

FB

MICROPAK

ADJ

OFF

ON

CONTROLLER

ADAPTER+

NODE

5

10

80

90

10

0

11

0

12

0

13

0

15

20

40

50

60

70

5

10

80

90

10

0

11

0

12

0

13

0

15

20

40

50

60

70

BEARING AIR

ATOM AIR

OUTER SHAPING AIR

INNER SHAPING AIR

P

-

O

U

H

S

- L

C

K

+

P

-

O

U

H

S

- L

C

K

+

P

-

O

U

H

S

- L

C

K

+

APPLICATOR ENABLE

PAINT TRIGGER

SOLVENT

CUP WASH

SHAPING AIR

OUTER

INNER

SHAPING AIR

AIR

CUP WASH

DUMP

FLUID ENABLE

SOLVENT IN

PAINT IN

CUP WASH

AIR IN

CUP WASH

BRAKE

MANUAL

AIR

BEARING AIR

DESC

MANUFACTURER

CAT

SHAPING AIR

100

0

OUTER

100

0

INNER

SHAPING AIR

ON

HIGH VOLTAGE

MANUFACTURER

CAT DESC

OFF

R

CONTROL

POWER

DESC

MANUFACTURER

CAT

FIBER OPTIC

TRANSCEIVER VOLTAGE

100

0

100

0

ATOMIZING AIR

LEAK TEST

0

160

FLUID

OFF

WATER

0

160

SUPPLY AIR

4

6

1

2

3

5

7

9

10

11

8

12

13

14

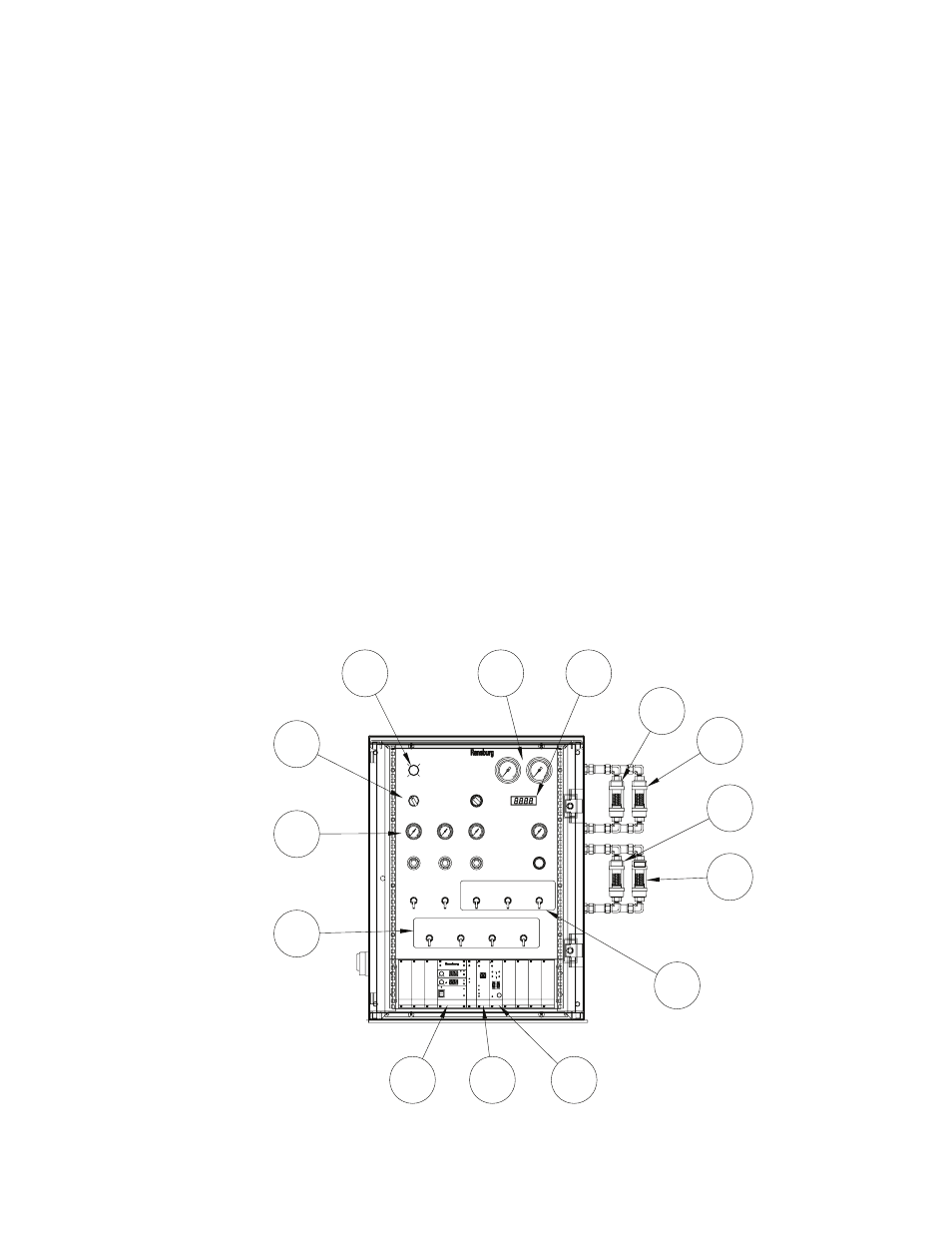

MMA-303 Test Station - Introduction

7

Figure 1b: Basic Station Features

1 Power Control - On/Off Button

2 Main Air Gauges - Leak Down, Supply Air

3 Fiber Optic Voltage Readout

4 Air Flow Meter - Atom Air

5 Air Flow Meter - Outer Shaping Air

6 Air Flow Meter - Bearing Air

7 Air Flow Meter - Inner Shaping Air

8 Fluid Enable - Paint In, Cup Wash Solvent In, Cup Wash Air In

9 Atomizer Speed Select Card

10 Atomizer Card

11 MicroPak Power Supply

12 Applicator Enable, Paint Trigger, Cup Wash Solvent, Cup Wash Air, Dump

13 Regulated Function Gauges - Bearing Air, Outer Shaping Air, Inner Shaping Air

14 High Voltage - On/Off Switch

LN-9255-06.2