Vh series, General pump – General Pump VH User Manual

Page 11

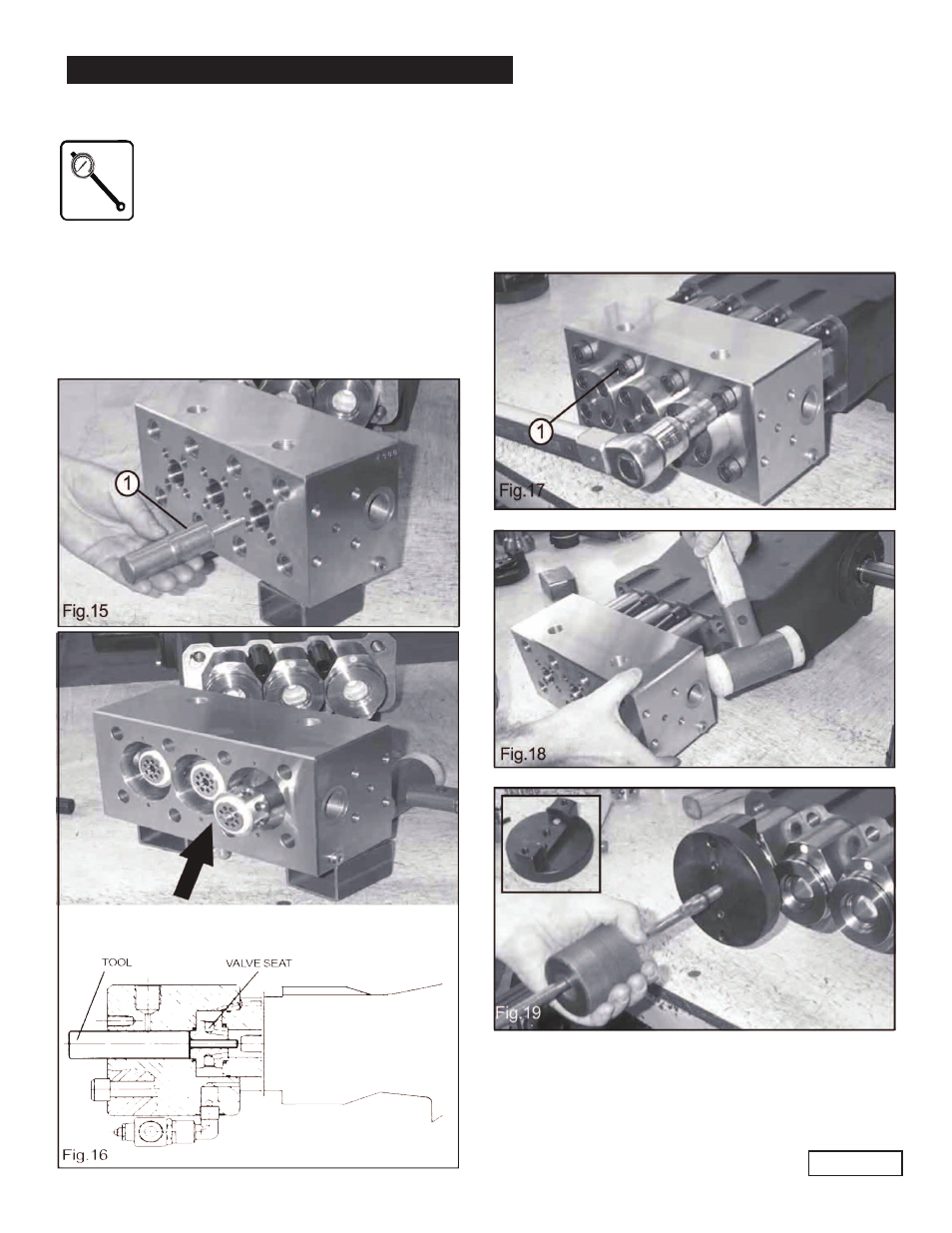

Remove the eight head screws (1, Fig. 17).

Once the head is removed the cylinders are free to be

taken out of the crankcase. Tapping the cylinders all

around with a plastic hammer helps loosen them from

possible scaling or deposit accumulated during use.

In order to facilitate the extraction of the cylinder the

tool p/n F200000180, or equivalent, is recommended

(Fig. 19).

Remove the pump head (see chapter 11.2).

GENERAL PUMP

A member of the Interpump Group

VH SERIES

Page 11

Reassemble valves and head back in place

by following the disassembling steps in the

opposite sequence and use a torque wrench

at the following settings for valve cover

screws and head screws:

-Valve cover screw: 54.2 ft. lbs.

-Head screws: 144.6 ft. lbs.

NOTE:

In order to facilitate reassembling operation use our tool

(1, Fig. 15) p/n F200000170, or equivalent, able to hold the

valve seat and valve poppet in place when mounting the

head on the pump (see arrow Fig. 16).

11.3 Pumping unit maintenance.

The only maintenance operation required for the pumping

unit is the visual check of the amount of water drained out

by the cooling system through the hole provided

underneath the head (Fig. 7, page 9). It clearly shows

the pressure packing state of wear. Pressure packings

should be replaced when vibration and/or drop in the

operating pressure start to occur during operation.