Vf series, General pump – General Pump VF Owner Manual User Manual

Page 9

GENERAL PUMP

A member of the Interpump Group

VF SERIES

Page 9

9.4 Hydraulic Connections

In order to isolate the system from the vibrations produced

by the pump, we advise to build the first section of the duct

near the pump (both for intake and delivery) with flexible

hose. The consistency of the intake section must allow to

avoid deformation caused by the depressurization

produced by the pump.

9.5 Pump Feeding

VF pumps require a minimum positive head (NPSH

r

)

ranging between 75 and 100 PSI (5 and 7 bar) measured

at head intake. The booster pump must have the following

characteristics: Flow rate of at least twice the value of the

plunger pump’s rated flow value, with a minimum pressure

of 75 PSI (5 bar). These feeding conditions must be

respected in all running conditions. Booster activation

must be independent from that of the plunger pump.

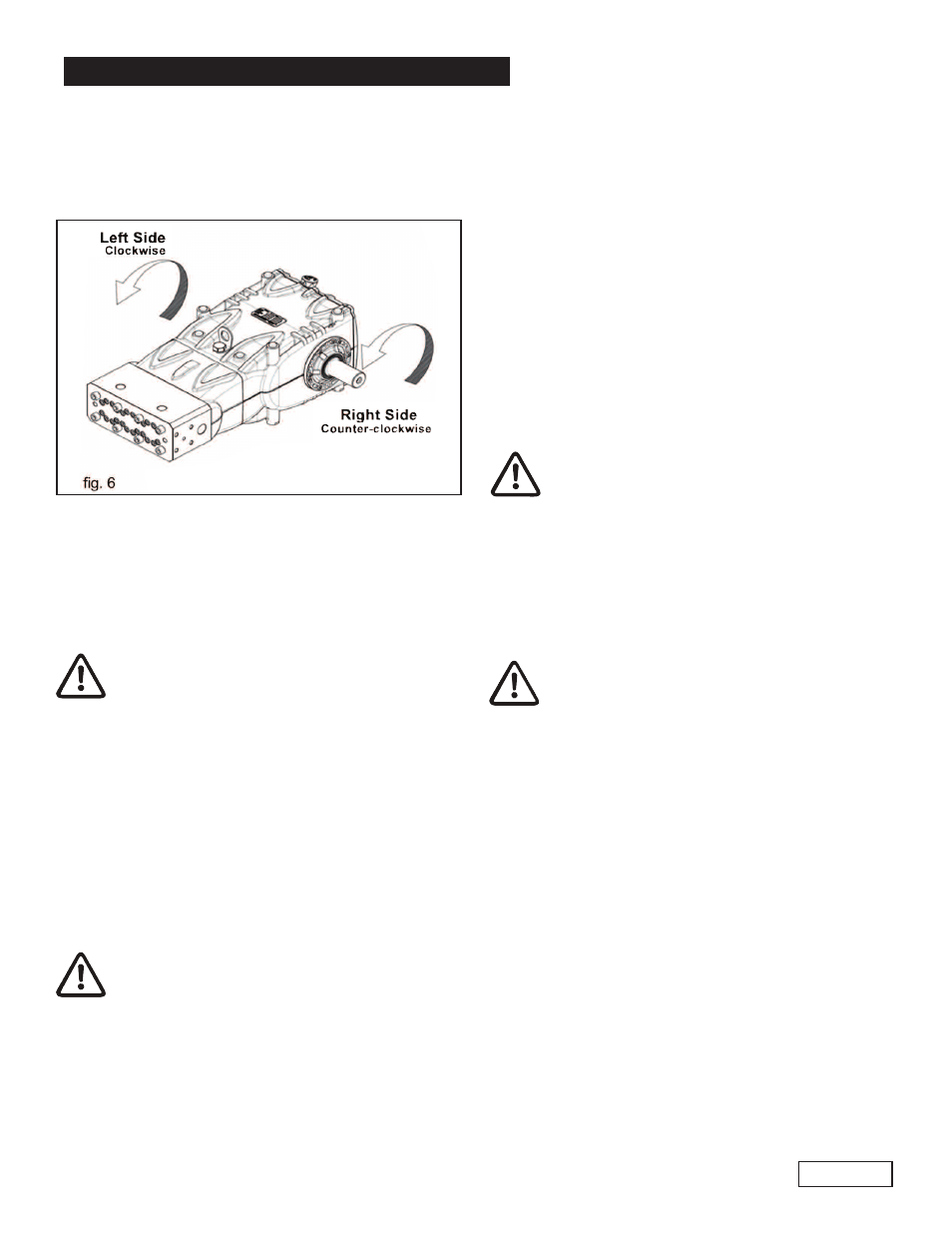

9.2 Direction of Rotation

An arrow situated on the crankcase near the shaft

indicates the correct direction of rotation. Standing in front

of the pump head, the direction of rotation must be as

shown in fig. 6.

9.6 Suction Line

For the pump’s correct operation, the suction line must

have the following characteristics:

1. Minimum internal diameter as indicated in the diagram

in paragraph 9.9, and in any case equal or greater than

the pump head’s value.

Along the duct, avoid localized diameter reductions

that may cause pressure drops with subsequent

cavitation. Absolutely avoid 90

0

elbows, connections with

other hoses, bottlenecks, counter-slopes, upside down “U”

shaped curves, “T” connections.

2. The selected lay-out must allow to avoid cavitation.

3. It should be perfectly airtight, and built in a way that

guarantees perfect sealing over time.

4. Avoid pump emptying when stopping (even partial

emptying).

5. Do not use hydraulic-type fittings,3 or 4 way fittings,

adapters, etc. , since they may hinder the pump’s

performance.

6. Do not install Venturi tubes or injectors for detergent

intake.

7. Avoid the use of standing valves, check valves, or any

other type of one-way valves.

8. Do not connect the by-pass line from the valve directly

to the pump suction line.

9. Provide appropriate baffle plates inside the tank in

order to avoid water that flows coming from both the by-

pass and feeding lines may create turbulence near the

tanks outlet port.

10. Make sure that the suction line is perfectly clean inside

before connecting it to the pump.

9.3 Version Change

A right version pump is defined when: observing the pump

from the head side, the PTO shank of the pump shaft is on

the right side.

A left version pump is defined when: observing the pump

from the head side, the PTO shank is on the left side.

The version may be changed only by

specialized and authorized personnel by care-

fully following the instructions that follow:

1. Separate the hydraulic part from the mechan-

ical part as indicated in Chapter 2, paragraph

2.2.1 of the repair manual.

2. Rotate the mechanical part by 180

0

, and repo-

sition the rear crankcase cover so that the oil

dipstick is facing upwards; reposition the lifting

bracket and the related closing caps in the

upper part of the crankcase; finally, correctly

reposition the identification plate in its

appropriate seat on the crankcase.

Be sure that the lower draining holes on

the crankcase near the plungers are open,

and not closed by the plastic caps that are

supplied.

3. Join the hydraulic part with the mechanical

part as indicated in Chapter 2, paragraph

2.2.2 of the repair manual.

Booster start-up must always precede plunger

pump start-up. In order to protect the pump,

we advise to install a pressure switch on the

feeding line after the filters.

Ref 300662 Rev.C

06-12