Vf series, General pump – General Pump VF Owner Manual User Manual

Page 8

GENERAL PUMP

A member of the Interpump Group

VF SERIES

Page 8

9. PUMP INSTALLATION

9.1 Installation

The pump must be installed in a horizontal position using

the correct threaded feet M16 x 1.5; fasten the screws with

a torque value of 155 ft. lbs. (210 Nm). The base must be

perfectly flat and sufficiently rigid in order to avoid bending

and misalignments on the pump/transmission coupling axis

due to the torque applied during operation. The unit must

not be rigidly fixed to the pavement, but requires the use of

anti-vibration elements. For special applications, please

contact the Customer Service Department.

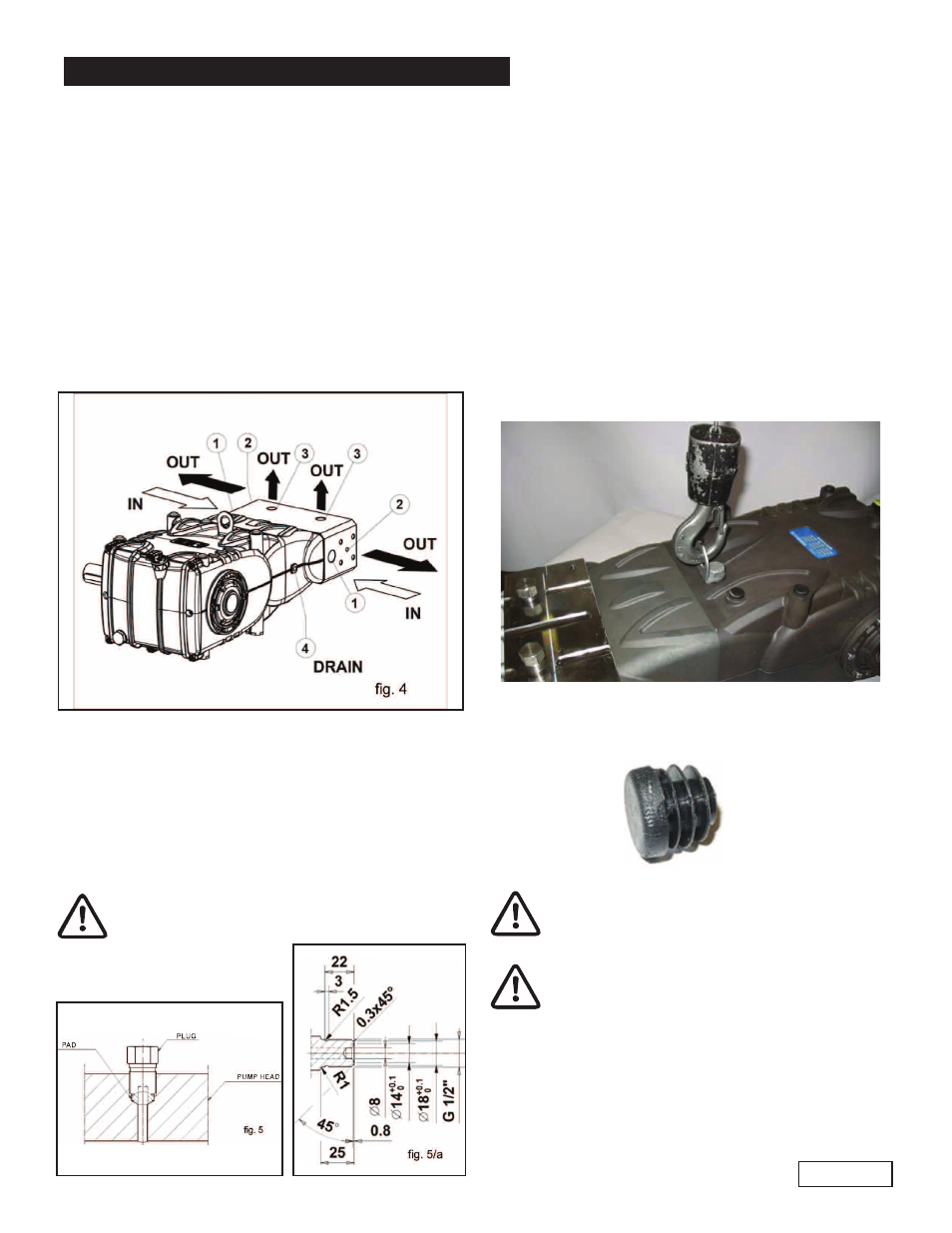

The pump is equipped with a lifting bracket to facilitate

installation as shown in the following figure.

8. PORTS AND CONNECTIONS

VF Series pumps (see fig. 4) are provided with:

1. 2 inlet ports “IN”, 3/4” Gas. The line can be connected

to either of the two inlet ports; the ones not being

used must be hermetically sealed.

2. 2 outlet ports “OUT”, Ø 8 mm

3. 2 auxiliary ports, 1/2” gas; they can be used for the

pressure gauge and the safety valve.

4. 1 drain port “DRAIN” supplied with an adjustable 90

0

rapid fitting for Ø 10 mm polyimide hoses; it is

needed to recover the fluid drained from the packing

cooling circuit, and must be connected to the outlet

port being careful to avoid counter-pressure.

8.1 Conic sealing pads

The VF pumps are equipped with 4 conic steel pads to be

used in correspondence of the pump’s delivery ports (fig. 5)

or in the optional fitting flanges. Their function is to guaran-

tee the sealing of the connection. The seat of the pump’s

delivery port is already machined in order to hold the conic

pad; if necessary, the connections for the delivery fitting or

the closing plug must be correctly machined as indicated in

fig. 5/a.

At each disassembly, the conic pad must be

replaced.

In case of disassembly, to avoid letting dirt inside the front

part of the crankcase, close the threaded hole with the

appropriate cap, supplied.

Replace the crankcase cap with the oil dipstick

and check oil level. The oil dipstick must always

be accessible, even when the unit is assembled.

The pump’s shaft (PTO) must not be rigidly

connected to the motor unit. The following

transmission

types

are

suggested:

• hydraulic by means of flange; for correct

application, please contact the Customer

Service Department

• Belts

• Cardan Joint (please respect the maximum

working angles indicated by the manufacturer)

• Flexible joint

Ref 300662 Rev.C

06-12