Ke series, General pump – General Pump KE Owner Manual User Manual

Page 15

GENERAL PUMP

A member of the Interpump Group

D) To Reassemble the valves proceed the

other way around, and tighten the cover

screws with a torque wrench. The table

on page 17 contains the screw tightening

torque values and Fig. 24 indicated the

sequence.

11.2.2 Seals

The replacement of the seals is necessary when water

drips through the holes provided on the crankcase.

For replacement, do as follows:

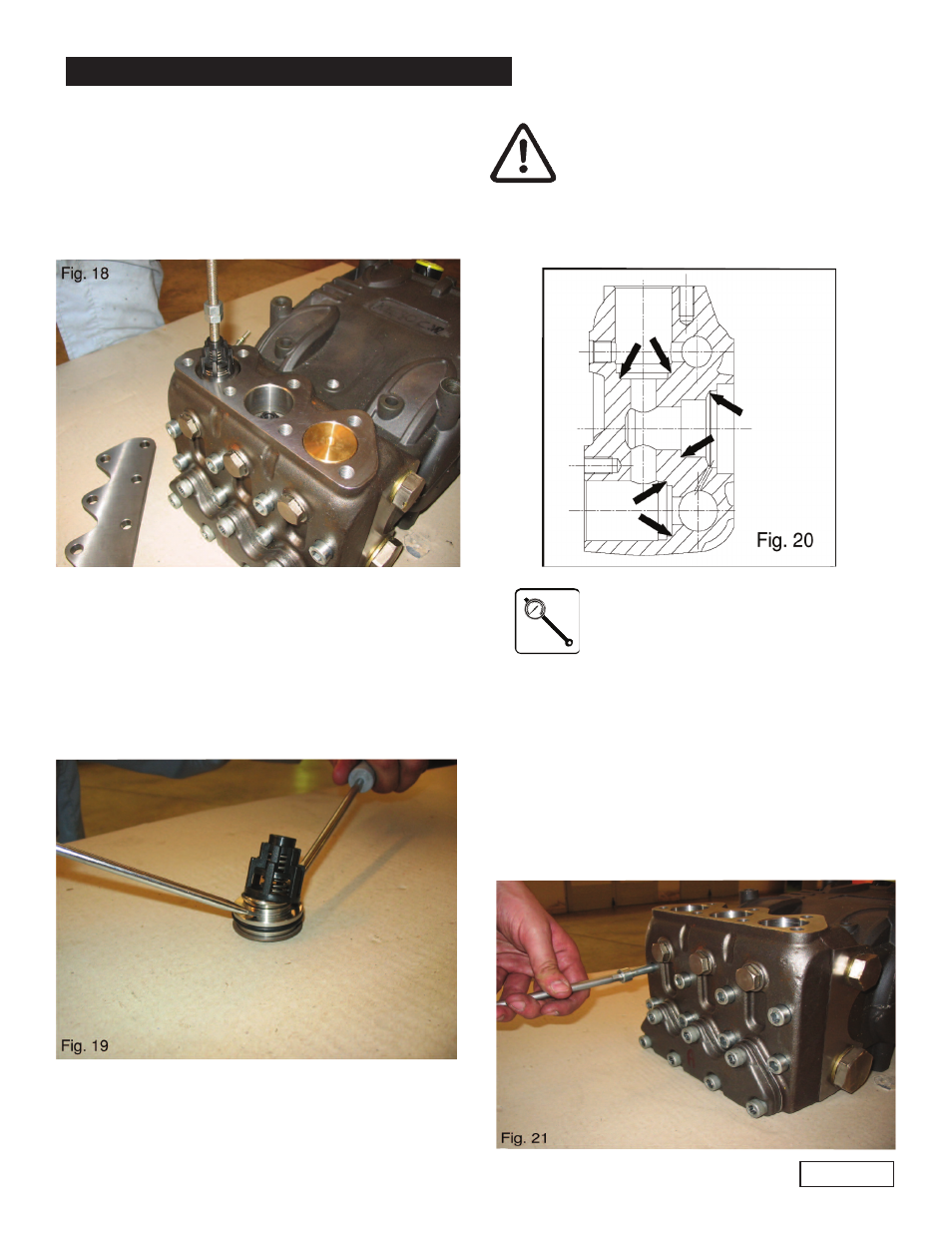

A) Remove the fluid end by loosening the 8 bolts (see

Fig 21).

KE SERIES

Page 15

11.2 Fluid end maintenance

11.2.1 Pump head

The fluid end does not require periodical maintenance.

Service operations are limited to the component

inspection and/or replacement, when necessary.

Valve Units:

A)

Loosen the valve cover screws.

B)

Extract the valve plugs with an extractor or a M8

threaded rod.

C)

Extract the valve unit with the same tool

See Fig. 18)

Valve components of each valve unit are pressed

together and therefore they can be easily replaced and

installed back in place by means of simple tools.

Check the components for wear and replace if necessary.

Replace all o-rings of the valve units and plugs, at

each inspection.

IMPORTANT NOTE:

BEFORE REPOSITIONING THE

VALVE UNITS AND O-RINGS CLEAN

AND PERFECTLY DRY ALL VALVE

HOUSINGS INSIDE THE FLUID END.