Ke series, General pump – General Pump KE Owner Manual User Manual

Page 12

GENERAL PUMP

A member of the Interpump Group

KE SERIES

Page 12

11.1.1 Crank mechanism disassembling

Do as follows:

A) Drain the oil from the pump and remove:

-shaft key

-back cover

-connecting rod cap

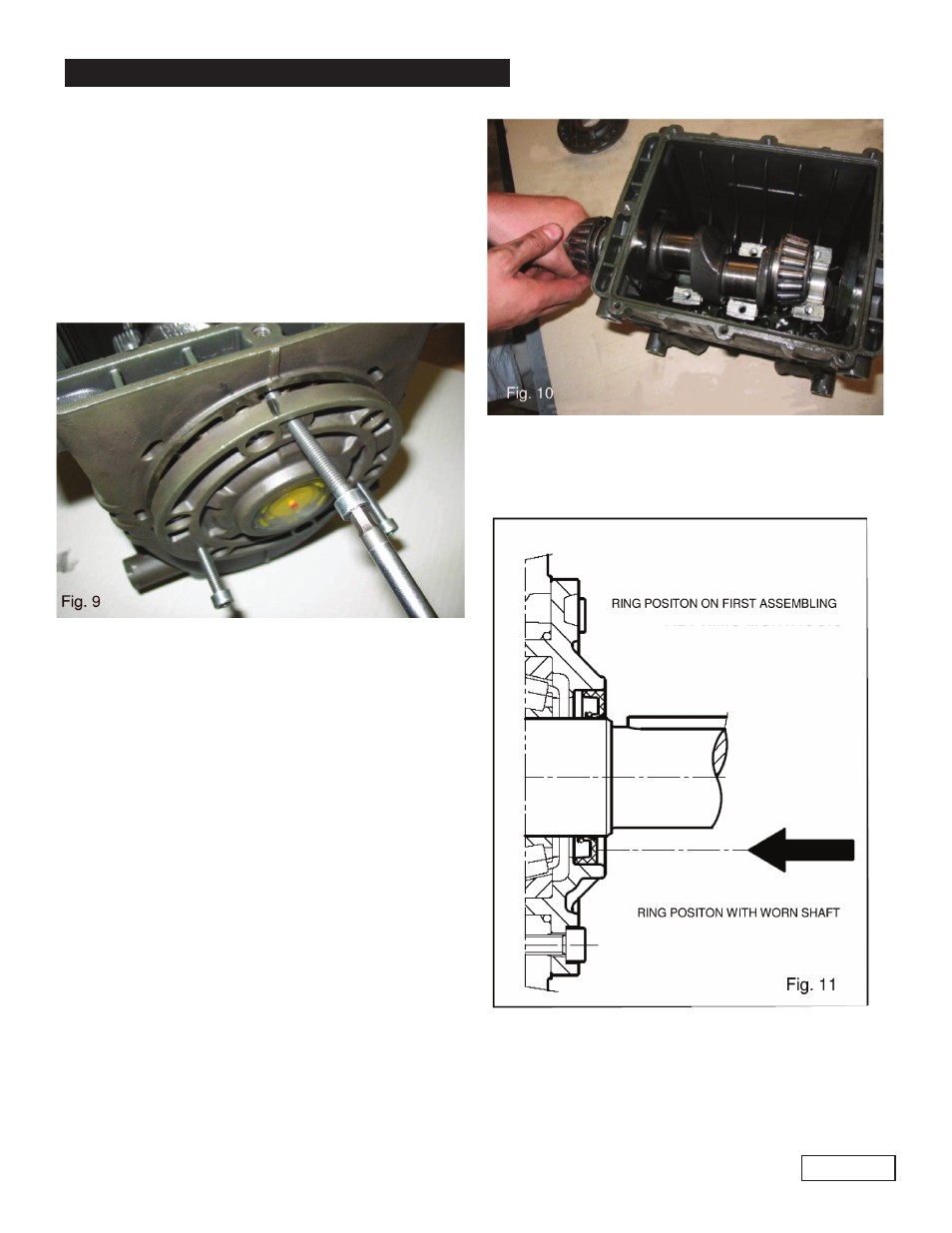

-side covers. To do so, put 3 screws M6 x 50 wholly

threaded into the holes drilled for that purpose. See

fig 9.

B) Push the piston guides and connecting rods forward

so you can remove the pump crankshaft from the side.

Note: to extract the piston guide, it is necessary to

remove the ceramic plunger and wiper first.

C) Disassemble the crankshaft oil seals and the piston

guides using standard tools.

11.1.2 Crank mechanism reassembling

After washing the crankcase, reassemble the power end

as follows:

A) Fit the piston guide seals into their seat thoroughly

making sure they are correctly positioned.

B) Introduce the units piston guide/connecting rod into

their seats (to facilitate the tightening of the connecting

rod cap position the connecting rod so you can easily

read the number). To install the crankshaft, without

key, it is necessary to push the unit piston guide/

connecting rod backward.

C) Before reassembling the side covers, check the seal

lips for wear. If they need replacing, fit the new ring

following the indications in Fig. 11.

Note: Should the shaft show diameter wear where there

is the seal lip, it is possible to avoid grinding by fitting the

seal further as indicated in Fig. 11. Before installing the

cover (sight glass side) check that the shim rings have

been placed. To help the covers fit on the crankcase, you

can use 3 screws M6 x 40, and then finish screwing

them with the original bolts M16 x 16.