Ke series, General pump – General Pump KE Repair Manual User Manual

Page 7

GENERAL PUMP

A member of the Interpump Group

KE SERIES

Page 7

B) Disassembly/assembly of the crankshaft with bearing replacement

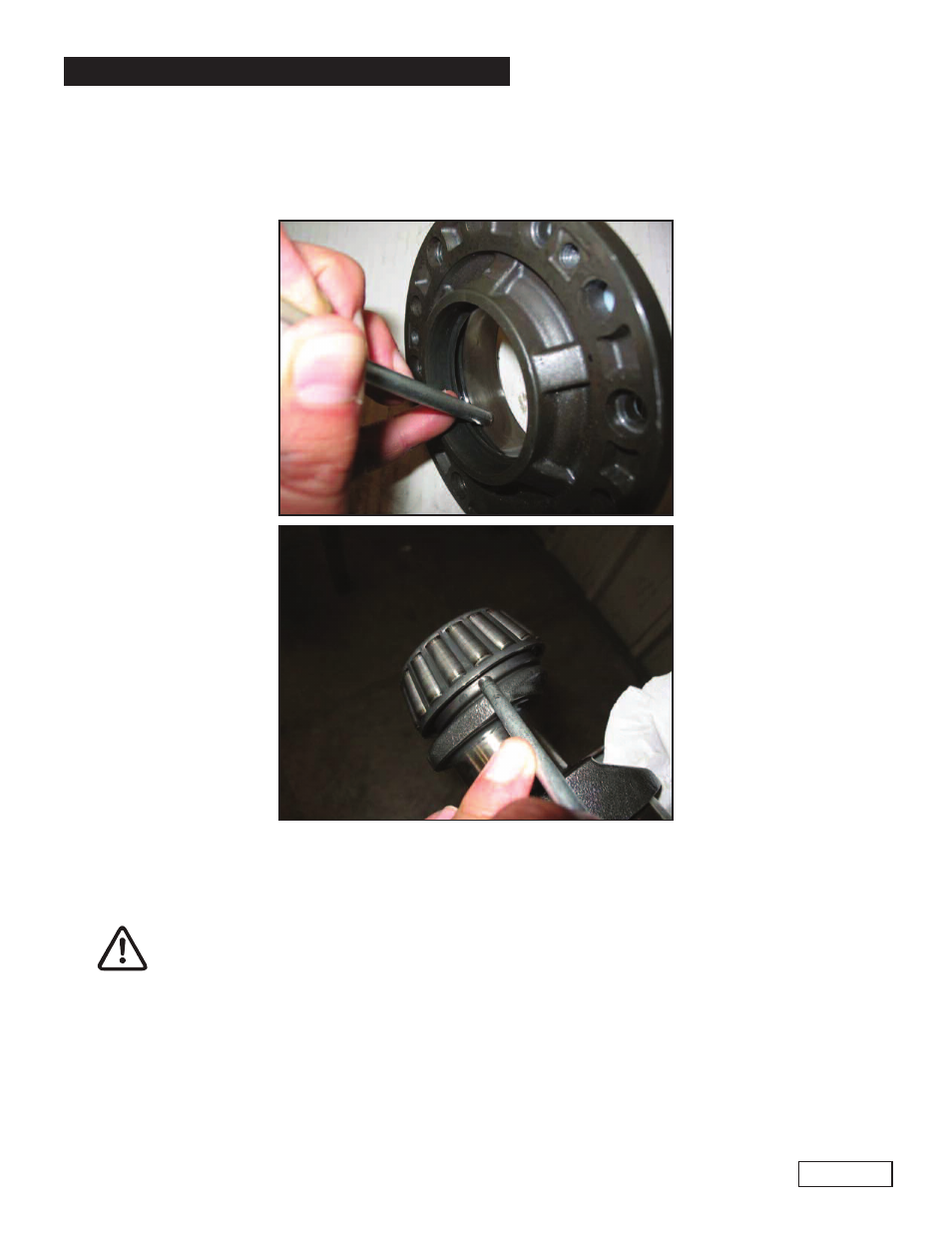

After disassembling the side covers as indicated in paragraph 2.1.1, remove the outer ring nut of the

bearings from their covers and the inner ring nut, with the remaining part of the bearing, from the two shaft

extremeties using a standard pin extractor or similar tool as indicated in figures 8 and 9.

fig. 8

fig. 9

The new roller bearing can be mounted at room temperature with a press or fly press; it is necessary to lay

them on the lateral side of the relevant ring nuts with correct rings. The driving operation can be facilitated

by heating the relevant parts at a temperature ranging between 250

0

-300

0

F (120

0

-150

0

C), making sure

that the ring nuts are correctly fitted into their seats.

Never invert the parts of the two bearings.

The shim pack must be redefined as follows:

A) Insert the crankshaft in the crankcase, being sure that the P.T.O. shank comes out of the correct side.

B) Fit the P.T.O. side flange to the crankcase paying great attention to the seal lip as indicated in paragraph

2.1.2, section C.

C) Position the flange on the sight glass side as indicated in paragraph 2.1.1.

D) Use a thickness gauge (see fig. 10).

Ref 300892 Rev.A

06-12